Light emitting diode and manufacturing process thereof

A technology for light-emitting diodes and manufacturing processes, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as increased manufacturing costs, reduced manufacturing efficiency, and inability to perform rapid drilling, so as to reduce manufacturing costs and reduce substrate waste. , The effect of improving the utilization rate of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A first preferred embodiment of the manufacturing process of the light-emitting diode of the present invention includes the following steps:

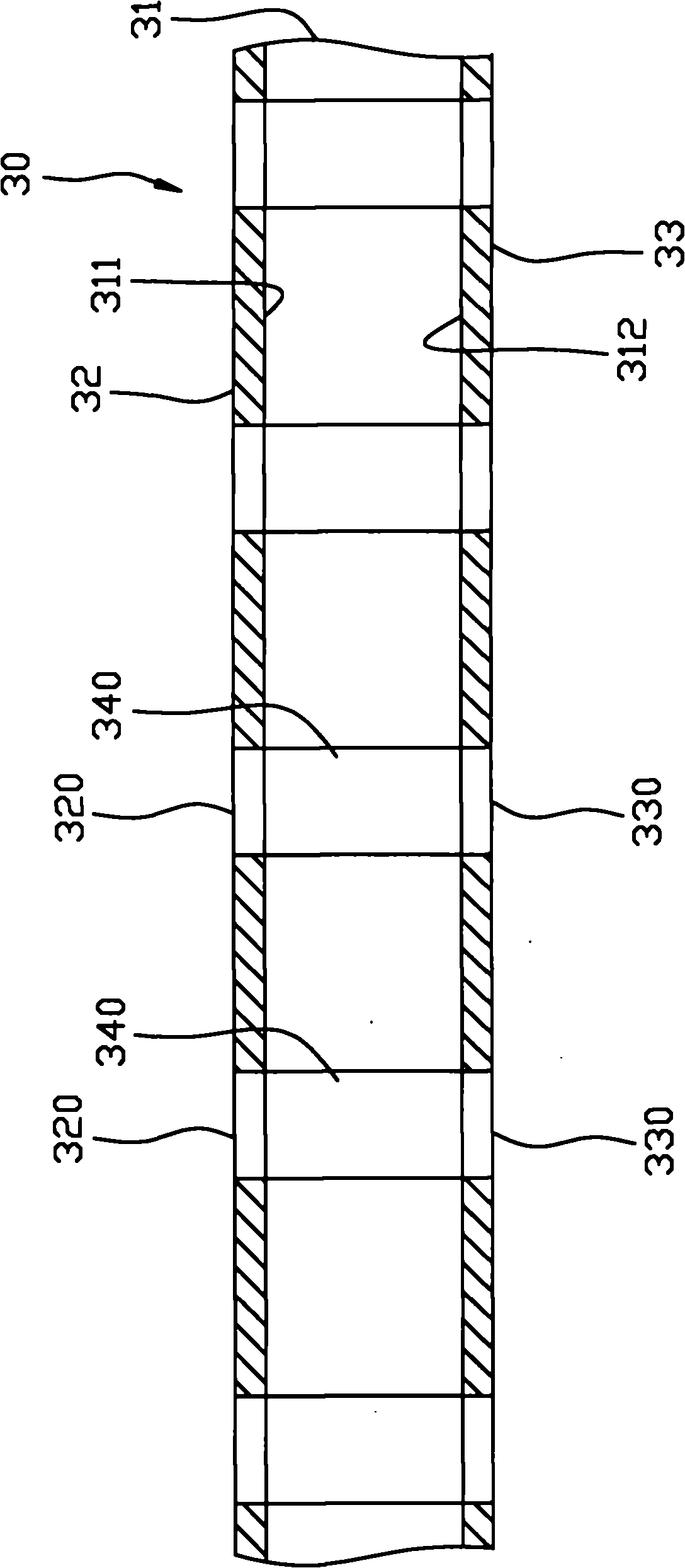

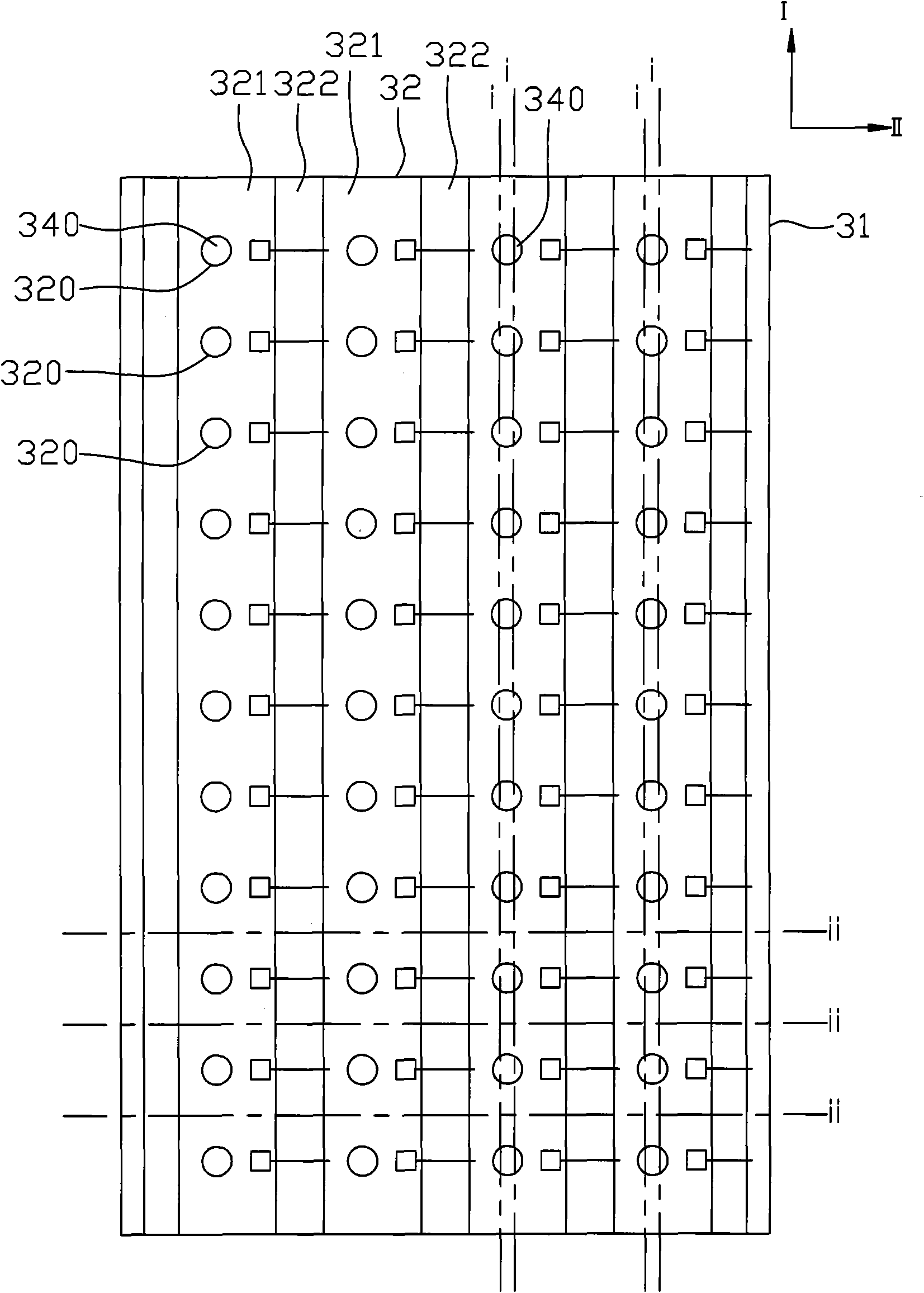

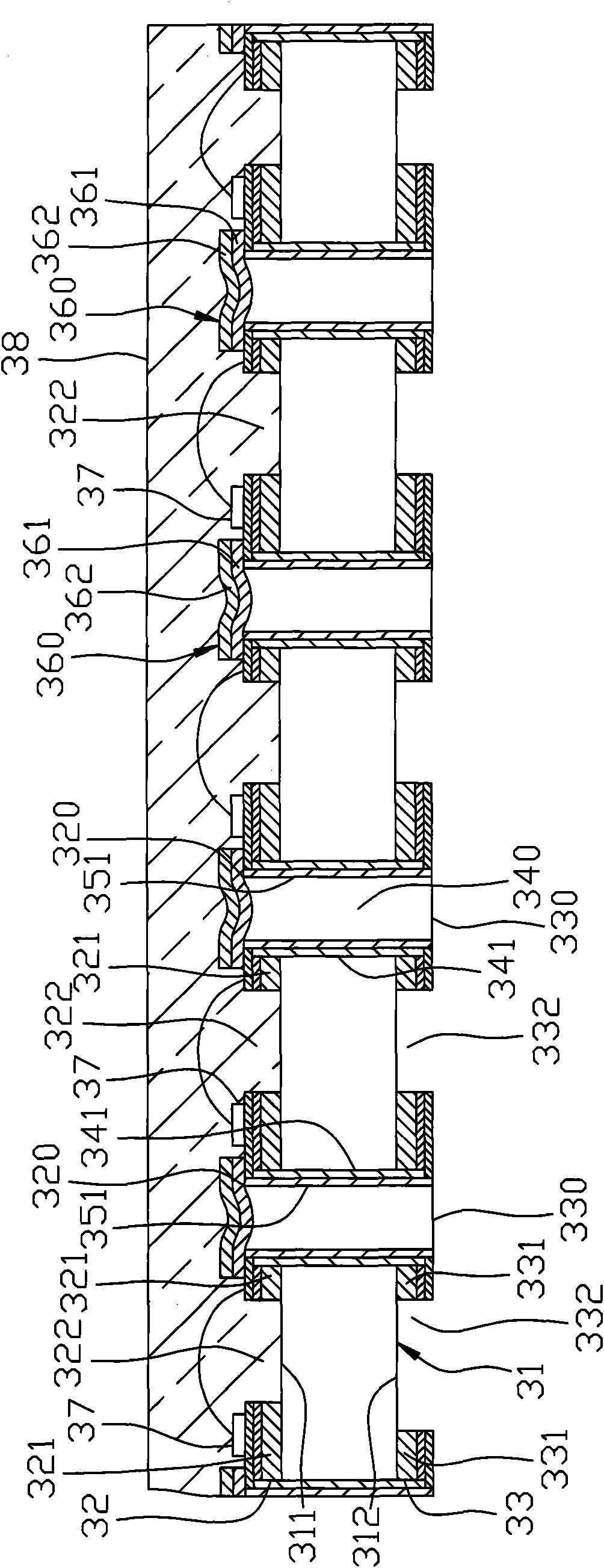

[0039] refer to figure 1 , figure 2 and image 3 , step 301 is to provide a substrate assembly 30, the substrate assembly 30 has a substrate 31, a plurality of upper electrode portions 321 arranged on an upper surface 311 of the substrate 31 at intervals along a first direction I, a plurality of interlayers The upper etched portion 322 between the upper electrode portions 321, a plurality of lower electrode portions 331 arranged at intervals along the first direction I on the lower surface 312 of the substrate 31, and a plurality of lower electrode portions 331 interposed between the lower electrode portions 331 The lower etching portion 332, a plurality of holes 340 spaced apart and penetrating the substrate 31 and the upper and lower electrode portions 321, 331, the holes 340 are respectively defined in the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com