Cavity filter and manufacturing method thereof, communication equipment and radio-frequency communication device

A cavity filter and radio frequency communication technology, which is applied in the field of communication, can solve the problems that screws affect the signal processing of the entire cavity filter, time-consuming assembly, high cost, and complicated process, and achieve low cost, good contact, and optimized communication The effect of indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

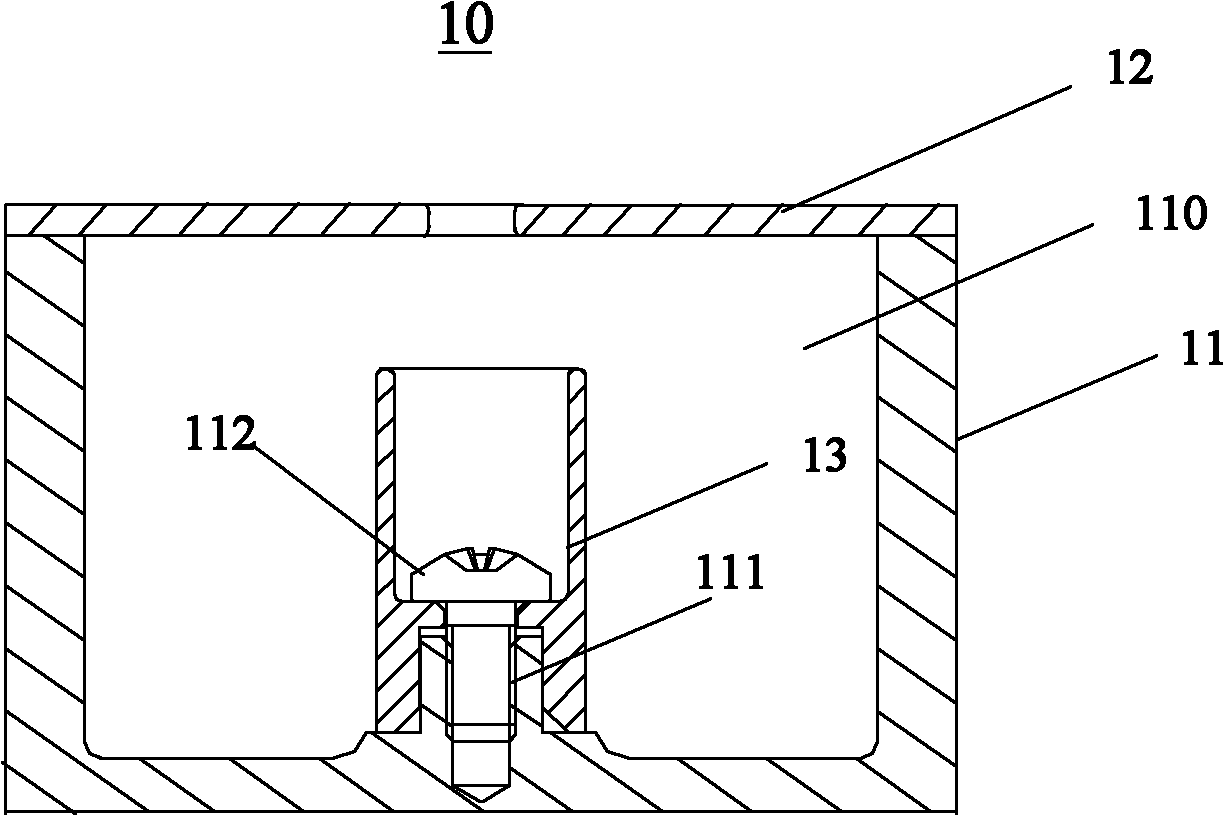

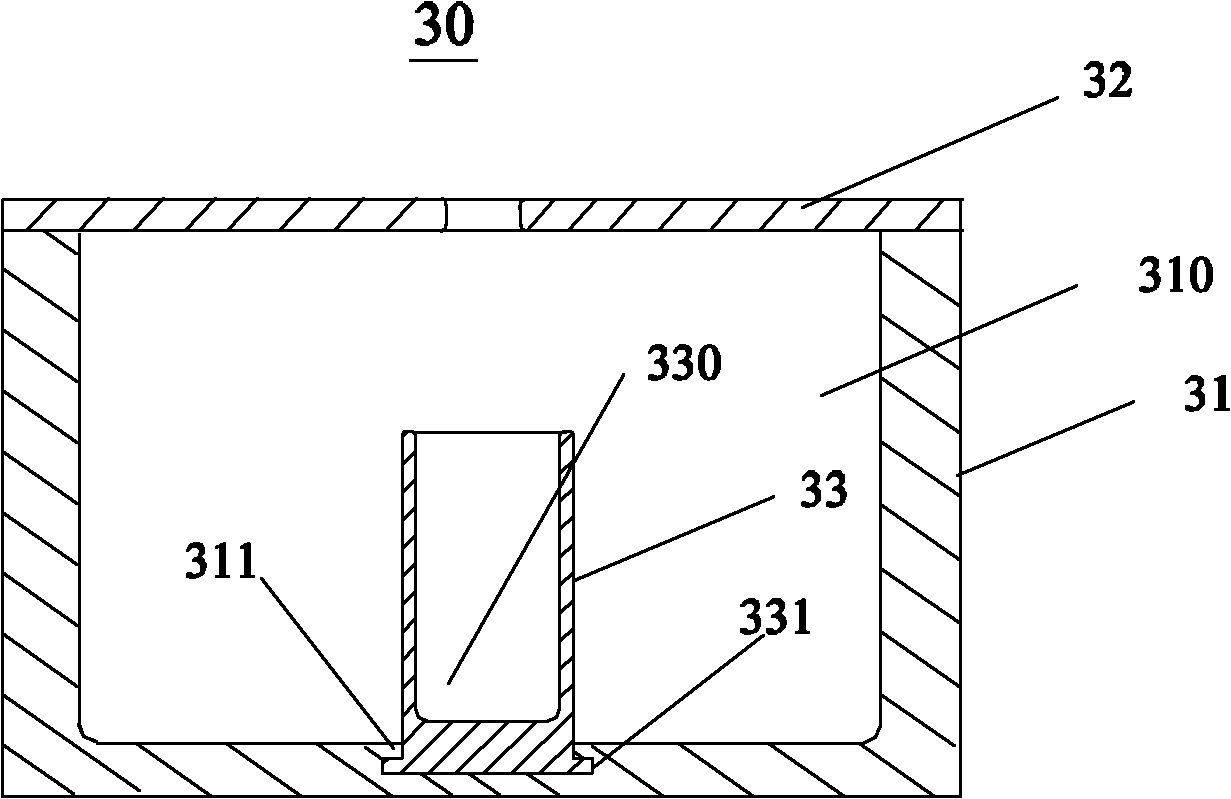

[0032] A cavity filter 30, such as image 3 As shown, the cavity filter 30 includes a cavity 31 , a cover plate 32 and a resonant rod 33 . The cover plate 32 covers the cavity body 31 to form a resonant cavity 310 . The resonant rod 33 is die-cast together with the cavity 31 or the cover plate 32 as an insert, and the resonant rod 33 is located at the bottom of the cavity 31 and has an integral structure with the cavity 31 .

[0033] In this embodiment, the bottom of the resonant rod 33 is embedded in the cavity 31, that is, the resonant rod 33 is integrally die-cast with the cavity 31 as an insert.

[0034] Specifically, the resonant rod 33 is first formed into an insert by stamping, die-casting or machining, and then the resonant rod 33 is used as an insert to die-cast together with the cavity 31, so that the resonant rod 33 and the cavity 31 are tightly embedded. connected into a single structure.

[0035] It is easy for those skilled in the art to understand that the re...

Embodiment 2

[0039] A cavity filter 40, such as Figure 4 As shown, the cavity filter 40 includes a cavity 41, a cover plate 42, and a resonant rod 43. In this embodiment, the general structure of the cavity filter 40 is the same as that in Embodiment 1, and the difference lies in the resonance The die-cast joint between the rod and the cavity is provided with a groove 432 for limiting the resonant rod inside the cavity. In order to facilitate the positioning of the resonant rod during the die-casting process, the resonant rod 43 may pass through the bottom of the cavity 41 and be arranged flush with the bottom surface of the cavity 41 .

[0040] Specifically, the recessed portion of the cavity filter 40 also has a second flange 412, and the resonant rod 43 also has a groove 432 matching the second flange 412, so that the resonant rod 43 communicates with the first flange 431 through the protruding portion 431. The matching of the flange 411 and the matching of the groove 432 and the seco...

Embodiment 3

[0042] A cavity filter 50, such as Figure 5 As shown, the cavity filter 50 includes a cavity 51 , a cover plate 52 and a resonant rod 53 . The cover plate 52 covers the cavity body 51 to form a resonant cavity 510 . The resonant rod 53 is die-cast in the resonant cavity 510 as an insert, and the resonant rod 53 is located at the bottom of the cavity 51 and has an integral structure with the cavity 51 .

[0043] In this embodiment, the resonant rod 53 and the cavity 51 can be made of different materials, for example, the resonant rod 53 can be made of copper or iron material, and the cavity 51 can be made of aluminum alloy or other materials, depending on the signal transmission characteristics and mechanical strength of the material. and material costs etc.

[0044] In a preferred embodiment, the thickness of the resonant rod 53 is smaller than the thickness of the cover plate 52 and the cavity 51, and the resonant rod 53 can be stamped from a thin plate. The resonant rod 53 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com