Deep-sea underwater direct current brushless motor for integrated driver

An integrated driver, DC brushless technology, applied in the direction of electric components, casing/housing/support, control of mechanical energy, etc., can solve the problems of not too long cable length, increased system cost, and high price of watertight connectors. Achieve the effects of large torque, large power volume ratio, and low system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In conjunction with the accompanying drawings, the present invention will be described in detail below through specific embodiments.

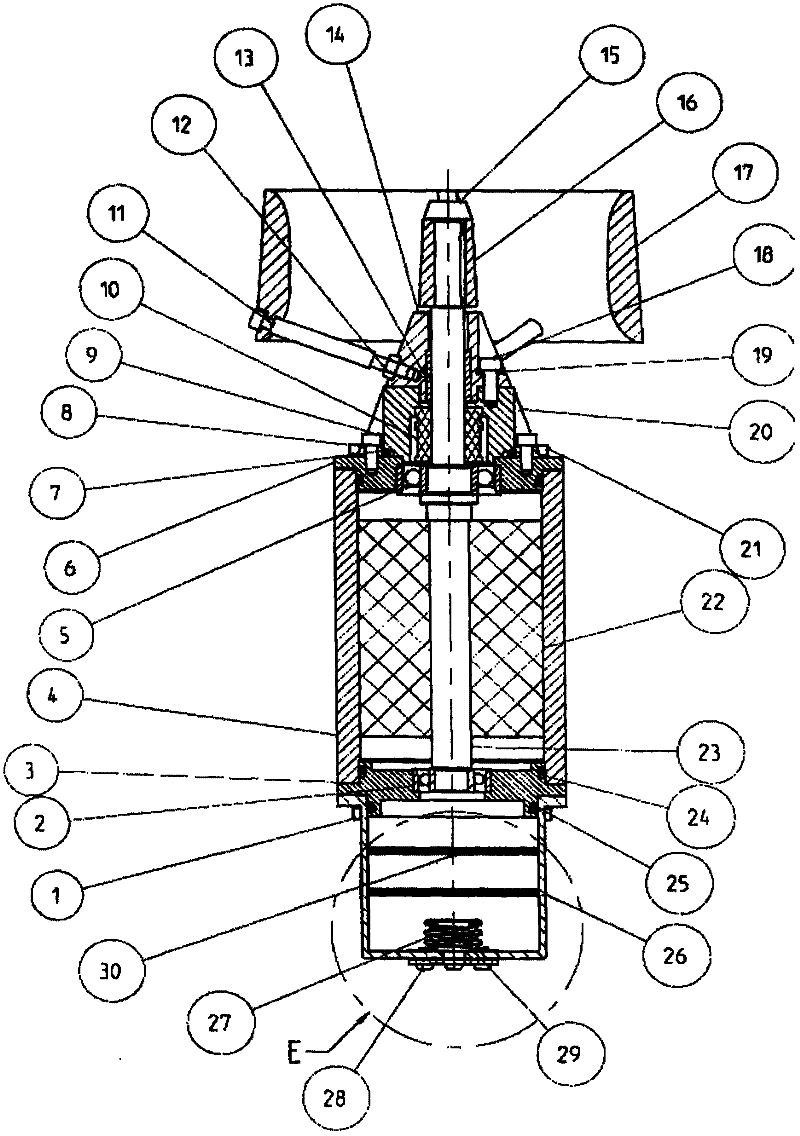

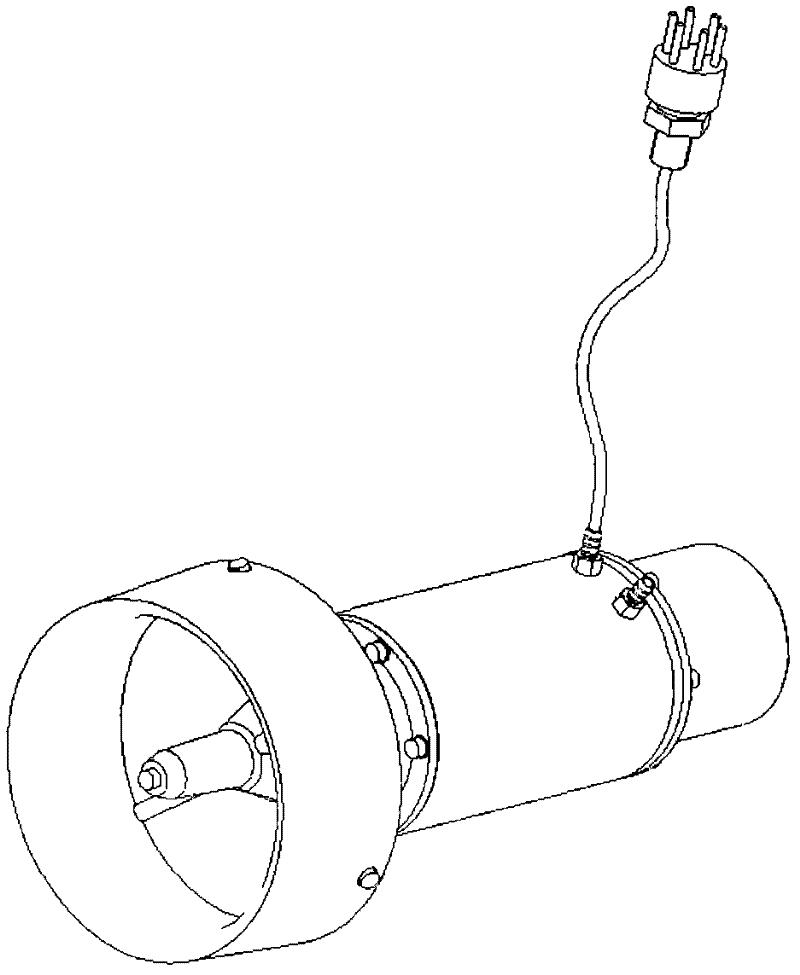

[0028] Such as figure 1 As shown, the brushless DC motor in the present invention is mainly composed of the following parts: brushless DC motor stator, rotor, sealing shell, output shaft end cover, terminal end cover, transition flange, mechanical seal and Mechanical seal compartment, driver compartment, watertight connector half-cable, etc.

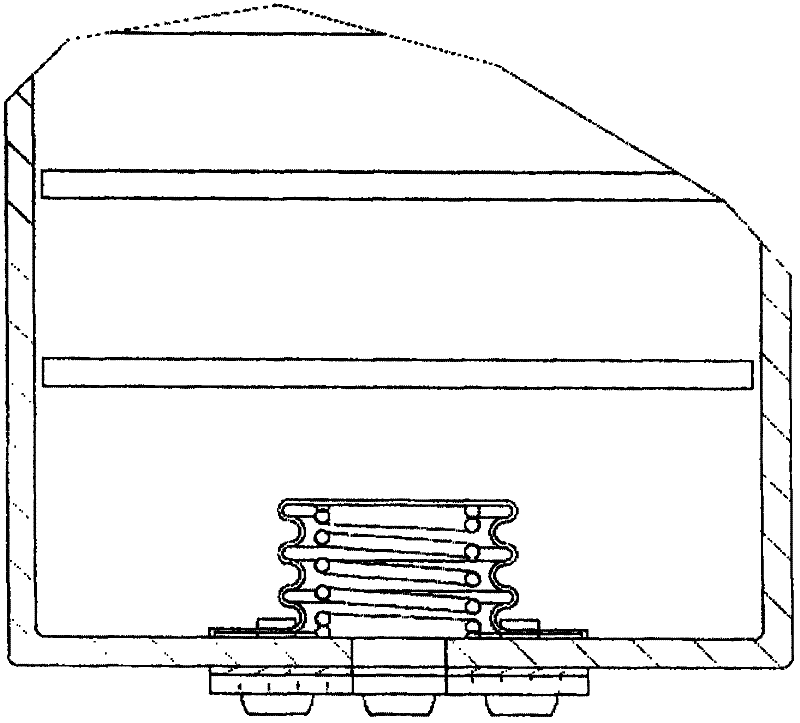

[0029] Both the DC brushless motor driver and the pressure compensator are placed in the driver cabin 26 , and the cables of the driver are inserted into the stator 22 through holes on the terminal cover 3 between the sealed housing 4 and the driver cabin 26 . There are two hose connectors on the sealed housing 4, one of which is used for connecting the hoses for power supply and control cables, and the other is used as an oil filling port. The cavity in the sealed case 4 is also communicated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com