Diazotization continuous tubular reactor

A tubular reactor, diazotization technology, applied in chemical instruments and methods, chemical methods for reacting liquids with liquids, organic chemistry, etc. to reduce separation and discharge, improve efficiency, and increase temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

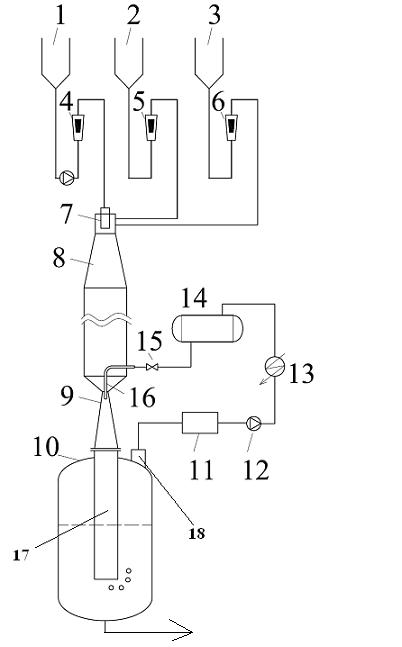

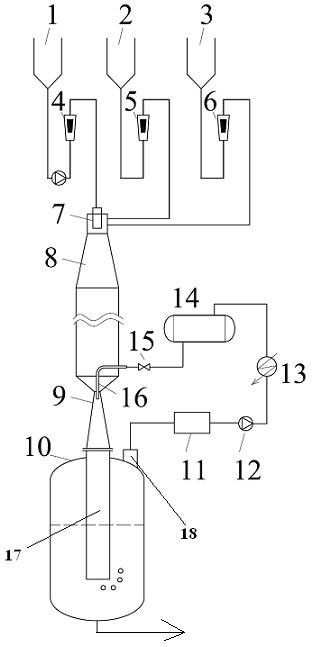

[0017] With reference to accompanying drawing, further illustrate the present invention:

[0018] The diazotization continuous tubular reactor includes a plurality of storage tanks 1, 2, and 3 for separately storing the reaction materials, and a tubular reactor 8 for performing the diazonium reaction, and obtains and stores the diazotization salt of the diazotization salt solution Separation storage tank 10, and cooling the circulating cooling system of the diazotization salt solution that reacts to generate in the tubular reactor 8;

[0019] All liquid storage tanks 1, 2, 3 are connected with the described tubular reactor 8 through a mixer 7 that can fully mix all the reaction materials and send them into the tubular reactor 8, and each liquid storage tank 1 , 2, 3 and the mixer 7 are provided with flow controllers 4, 5, 6, and the mixer 7 is sealed with the tubular reactor 8;

[0020] Described circulating cooling system comprises the quick cooler 9 that connects the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com