4-dimethylaminopyridine supported catalyst used for preparation of menthol ester lactate

A technology of dimethylaminopyridine and supported catalysts, applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, carboxylate preparation, etc., can solve the problem of not giving yield, not giving Synthetic reaction details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

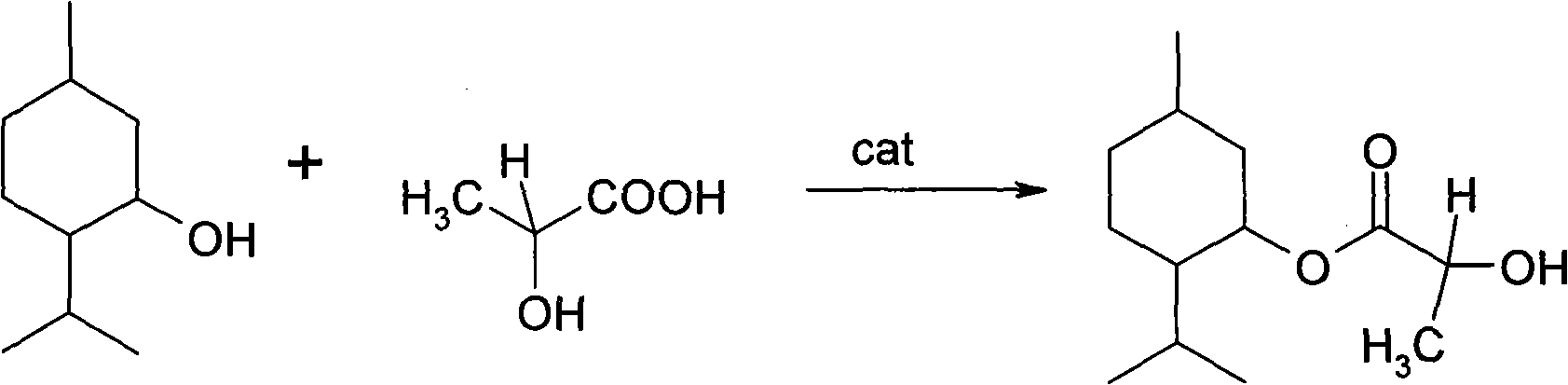

Method used

Image

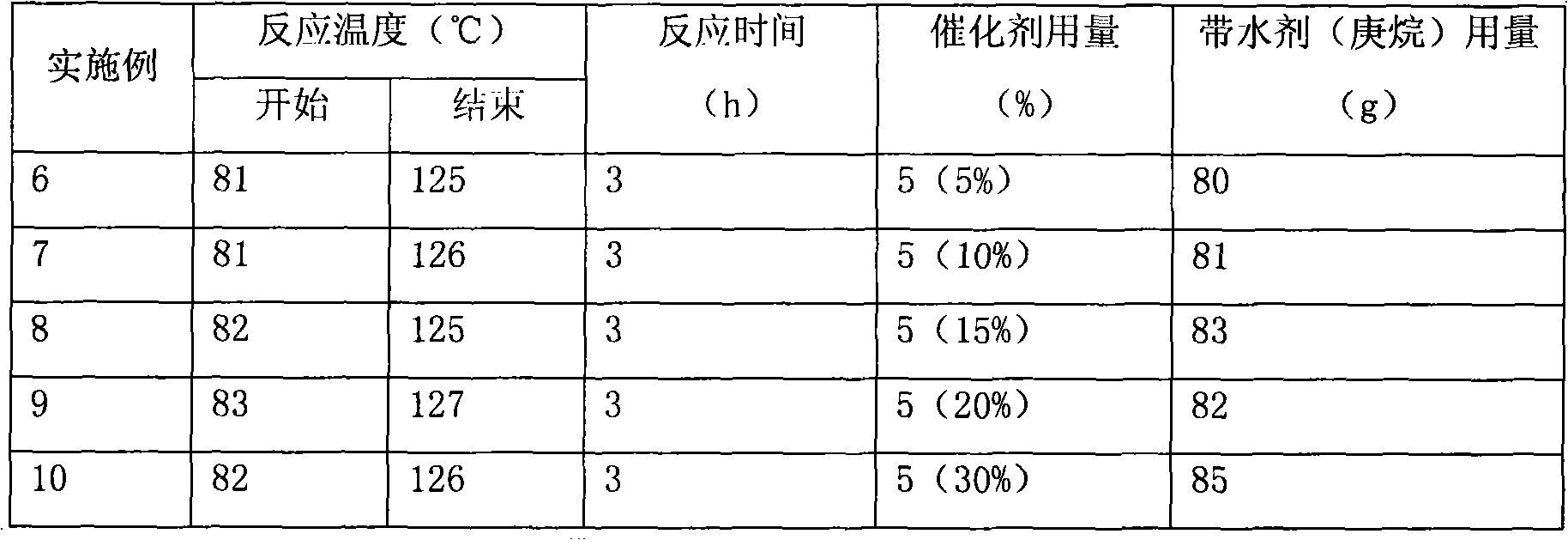

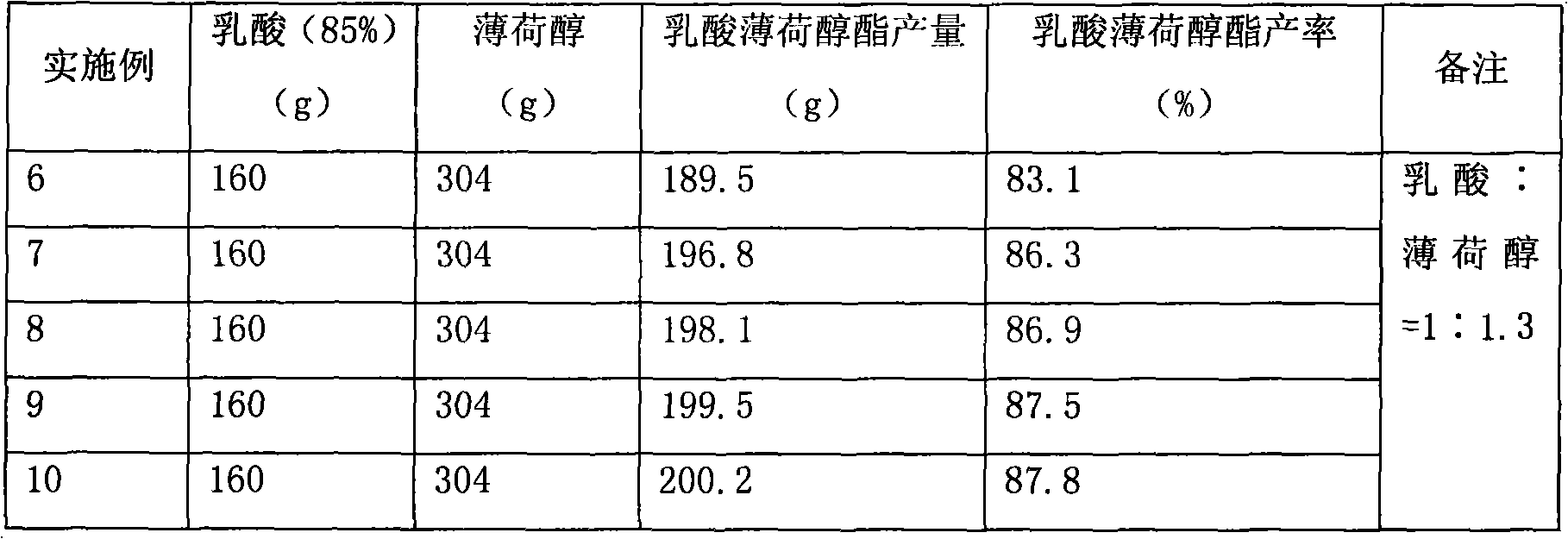

Examples

Embodiment 1

[0023] Preparation of 5% 4-dimethylaminopyridine / attapulgite catalyst

[0024] Weigh 4-dimethylaminopyridine (C 7 h 10 N 2 ) 1g, be dissolved in 95% ethanol, take by weighing attapulgite 19g roasted at 150 ℃ for 4 hours and mix with 4-dimethylaminopyridine solution, the impregnation medium is 95% ethanol, solid-to-liquid ratio (impregnation medium volume and carrier Mass ratio) 1mL / g. Stir at room temperature for 20 minutes, let stand for 1 hour, and then stir for 10 minutes; after the catalyst filter cake is air-dried, keep it in an oven at 80°C for 1 hour, and then activate it at 160°C for 2 hours to obtain 5% 4-dimethylaminopyridine / Attapulgite catalyst.

Embodiment 2

[0026] Preparation of 10% 4-dimethylaminopyridine / attapulgite catalyst

[0027] Weigh 4-dimethylaminopyridine (C 7 h 10 N 2 ) 2g, be dissolved in 95% ethanol, take by weighing attapulgite 28g roasted at 200 ℃ for 3 hours and mix with 4-dimethylaminopyridine solution, the impregnation medium is deionized water, solid-to-liquid ratio (impregnation medium volume and carrier Mass ratio) 3mL / g. Stir at room temperature for 20 minutes, let stand for 1 hour, and then stir for 10 minutes; after the catalyst filter cake is air-dried, keep it in an oven at 85°C for 2 hours, and then activate it at 150°C for 1.5 hours to obtain 10% 4-dimethylaminopyridine / Attapulgite catalyst.

Embodiment 3

[0029] Preparation of 15% 4-dimethylaminopyridine / attapulgite catalyst

[0030] Weigh 4-dimethylaminopyridine (C 7 h 10 N 2 ) 4g, be dissolved in 95% ethanol, take by weighing attapulgite 16g roasted 2 hours at 220 ℃ and mix with 4-dimethylaminopyridine solution, impregnation medium is 95% ethanol, solid-to-liquid ratio (impregnation medium volume and carrier Mass ratio) 5mL / g. Stir at room temperature for 20 minutes, let stand for 1 hour, and then stir for 10 minutes; after the catalyst filter cake is air-dried, keep it in an oven at 90°C for 2.5 hours, and then activate it at 140°C for 2 hours to obtain 20% 4-dimethylaminopyridine / Attapulgite catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com