Weir-pivoted decanter

A plate weir decanter and flap technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of expensive manufacturing and maintenance costs, limited decanting load, problems such as poor decanting effect, to achieve the effect of reducing maintenance costs, small sludge disturbance, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

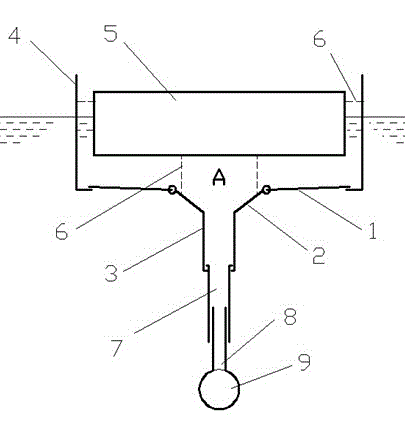

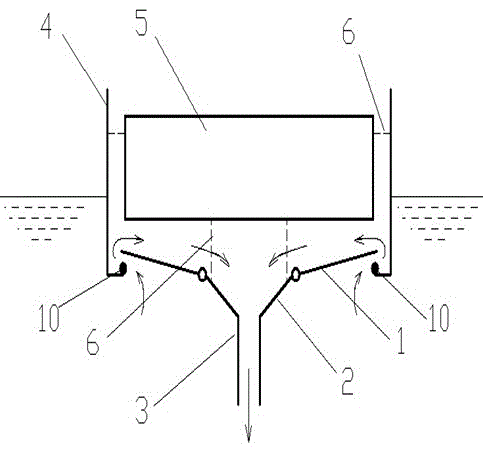

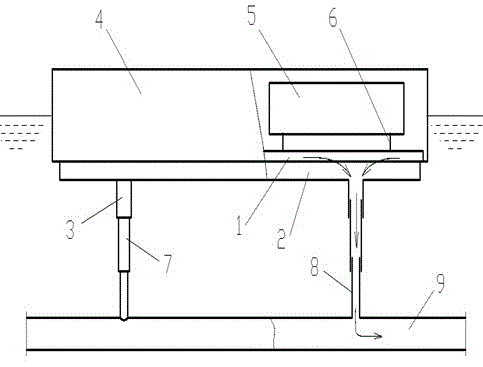

[0031] Example 1 as Figure 1 to Figure 4As shown, the flap weir decanter of the present invention includes an outer barrel box 4, the bottom of the outer barrel box 4 is connected with a diversion cone groove 2, and the lower end of the diversion cone groove 2 is connected with a drainage branch pipe 3, The drainage branch pipe 3 is set on the support pipe 8, and the support pipe 8 is connected to the drainage pipe 9. It is characterized in that: the outer barrel box 4 is connected with a buoyancy tank 5, and the diversion cone groove 2 The upper end of the tank is movably connected with a flap 1, and the flap 1 cooperates with the inner bottom of the outer barrel box 4 to form a decanting weir. The buoyant tank 5 is connected to the inner side wall of the outer tank 4 through the connecting rod 6 , and there is a gap between the buoyant tank 5 and the inner side wall of the outer tank 4 . The connecting pipe 7 is set inside the drainage branch pipe 3, and the connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com