Lubrication structure of active valve mechanism

A lubricating structure and moving valve technology, applied in the lubrication of valve accessories, etc., can solve problems such as increased capacity, achieve the effects of reduced oil capacity and shortened oil return time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

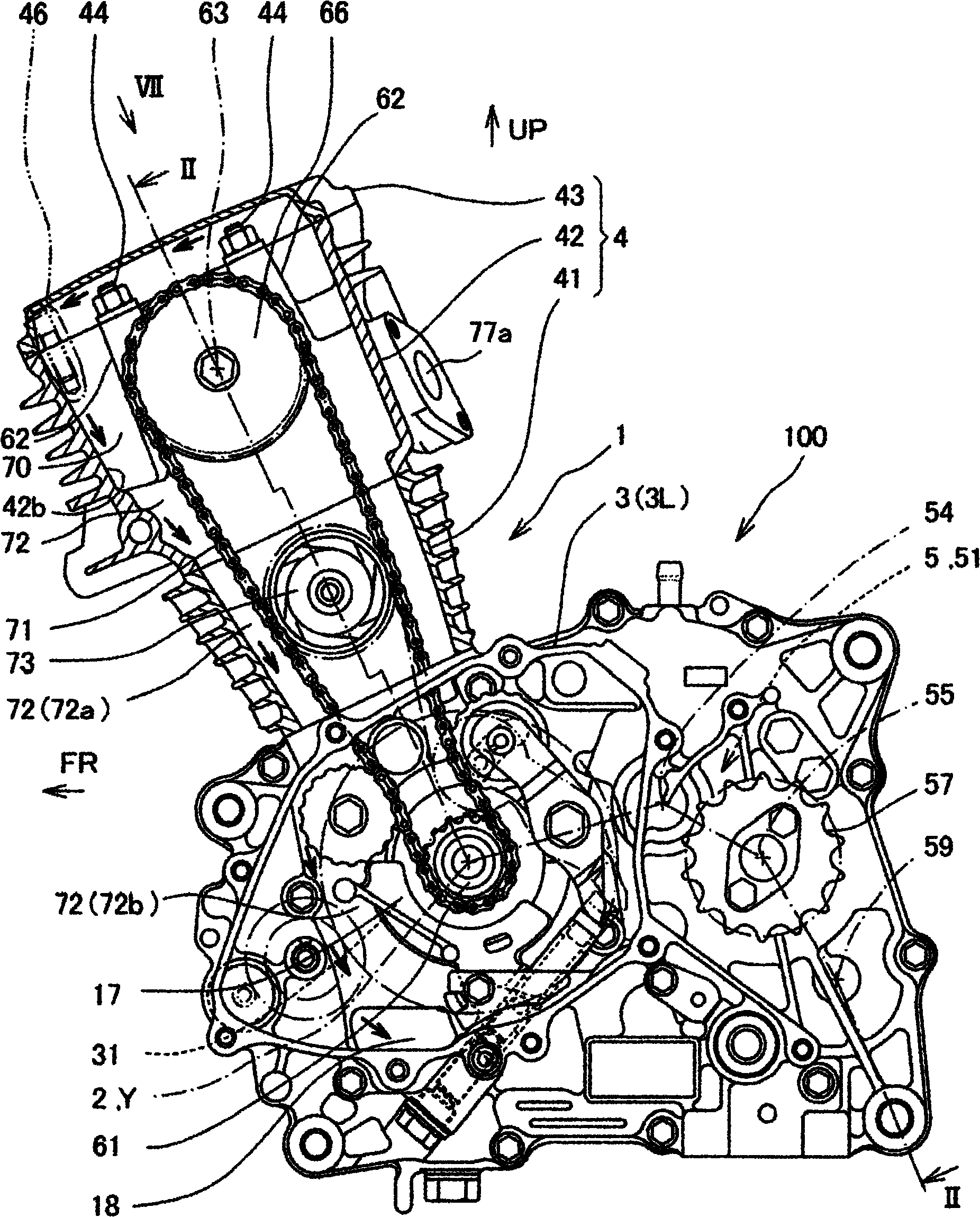

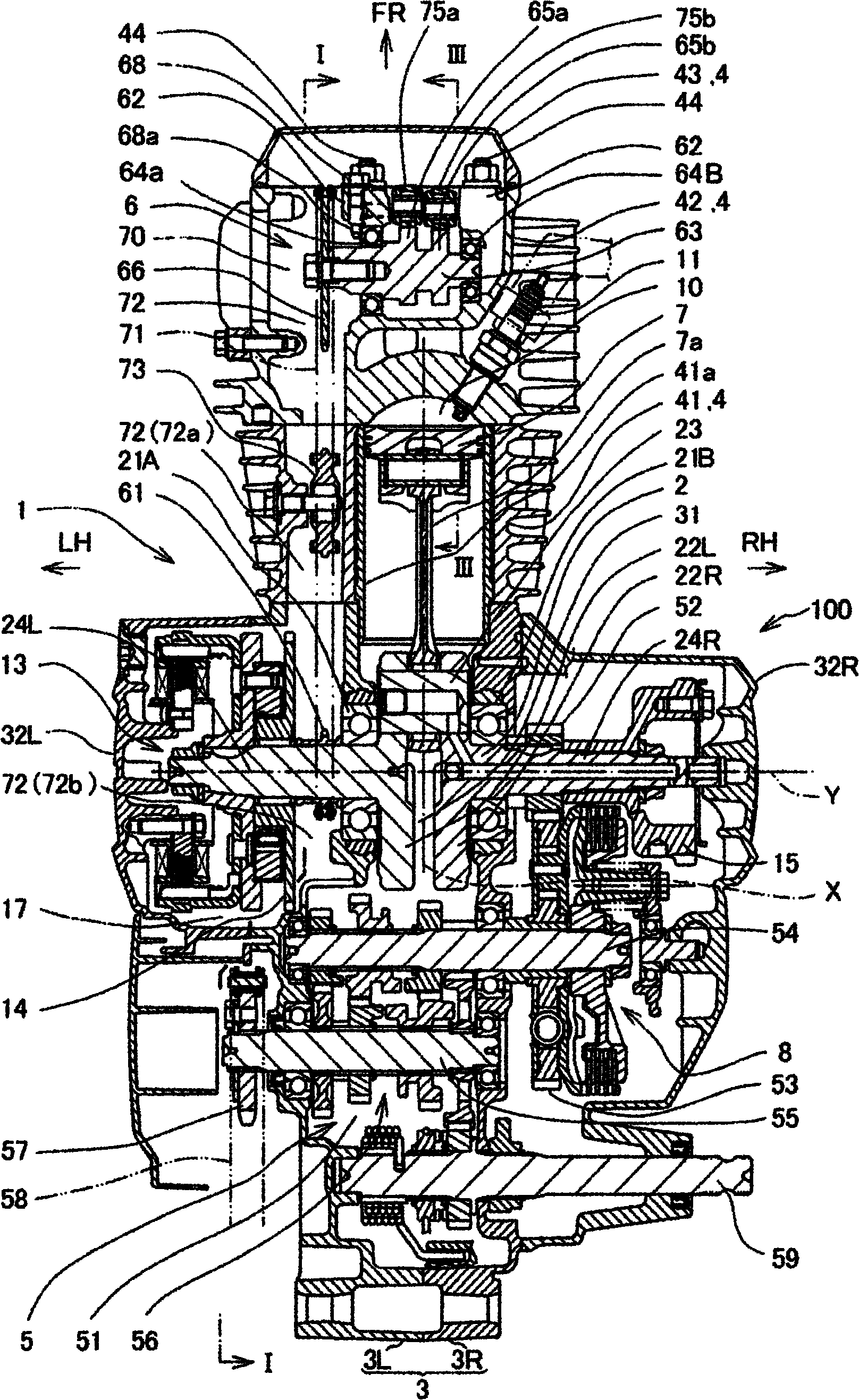

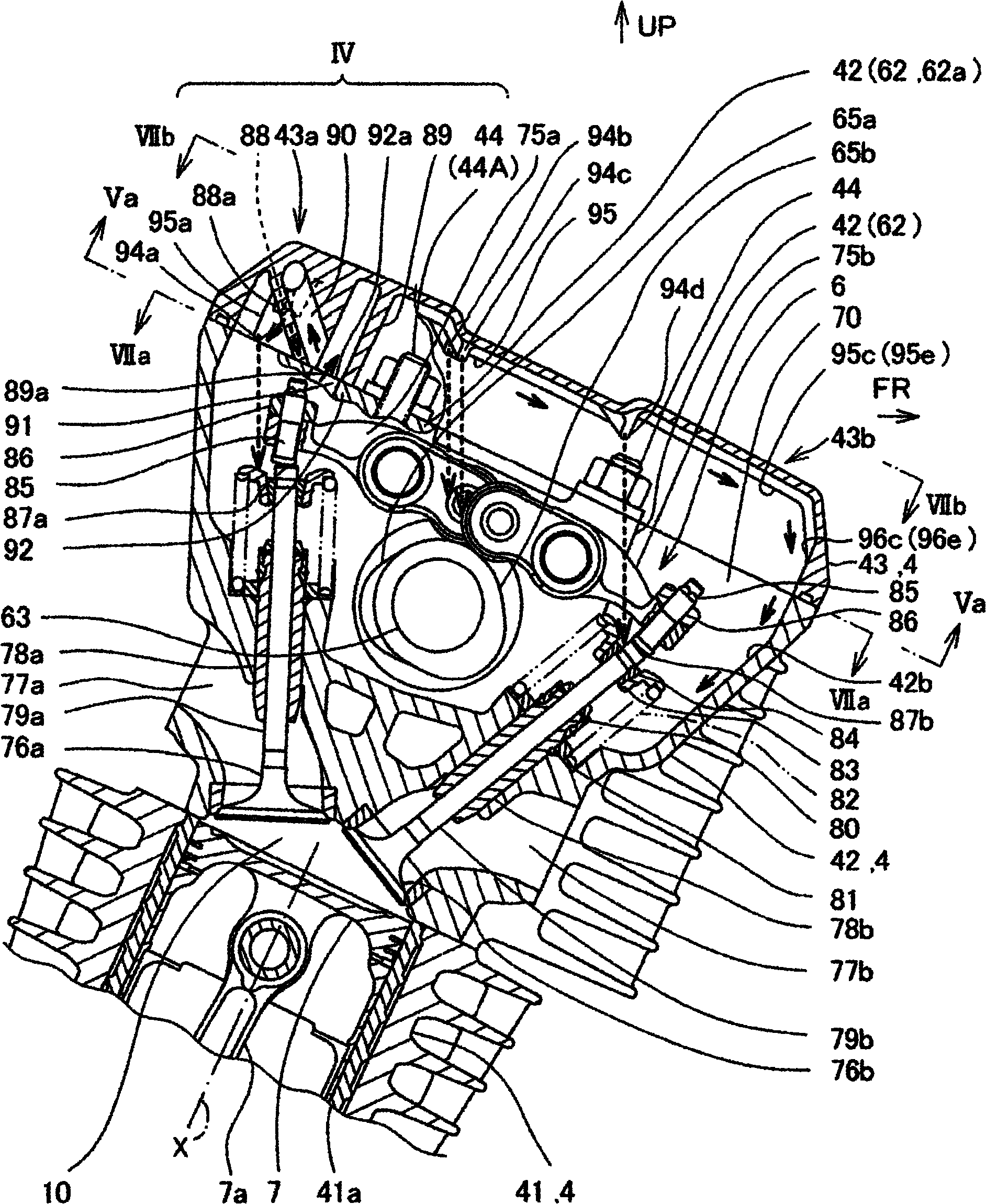

[0037] according to Figure 1 to Figure 11 , the lubricating structure of the movable valve mechanism of the internal combustion engine according to the first and second embodiments of the present invention, and the lubricating structure of the movable valve mechanism of other embodiments related to the present invention studied by the present inventors will be described.

[0038] Small arrows attached to devices and structural parts in each figure schematically indicate the flow of lubricating oil.

[0039] In addition, directions such as front, rear, left, right, up and down in this specification correspond to the direction of the vehicle in a state where the internal combustion engine of each embodiment is mounted on a vehicle such as a motorcycle.

[0040] In the drawings, an arrow FR indicates the front of the vehicle, an arrow LH indicates the left side of the vehicle, an arrow RH indicates the right side of the vehicle, and an arrow UP indicates the upper side of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com