Countercurrent cooler

A counter-current cooling and shell technology, applied in heat exchanger types, direct contact heat exchangers, lighting and heating equipment, etc., can solve problems such as poor cooling uniformity, uneven airflow, and material accumulation, and achieve reliability High, uniform flow field distribution, good transmission rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is further explained:

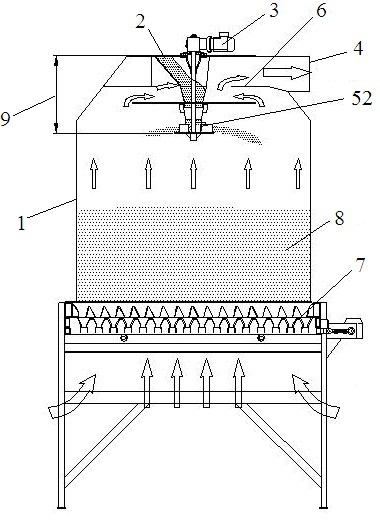

[0019] Such as figure 1 As shown, the counterflow cooler includes a circular shell 1 with an inner chamber, a feed port 2, a motor 3 and a discharge structure 7; the feed port 2 is arranged on the upper part of the shell 1, preferably at the top; the air suction port 4 can be It is arranged on the side of the upper part of the casing 1; the motor 3 can be arranged on the casing 1, or it can be separated from the casing 1 in a split manner, and the discharge mechanism 7 is arranged at the bottom of the casing 1.

[0020] A feed pipe 11 is provided in the housing 1 to communicate with the feed port 2, a rotating shaft 34 is provided in the feeding pipe 11 to connect with the motor 3, and a material uniform distribution mechanism 5 is provided at the bottom of the rotating shaft 34.

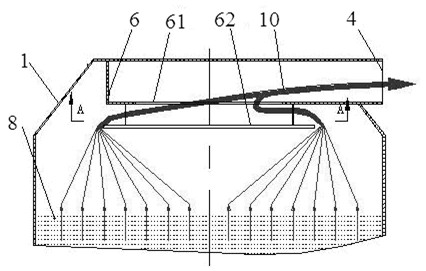

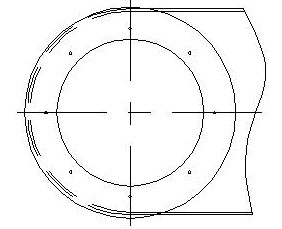

[0021] Such as figure 2 with image 3 As shown, the air duct 6 is arranged in the housing 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com