Method for distinguishing temperature of submersible motor based on lumped parameter model

A thermal network model, submersible motor technology, applied in the temperature measurement of moving solids, electrical digital data processing, special data processing applications, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

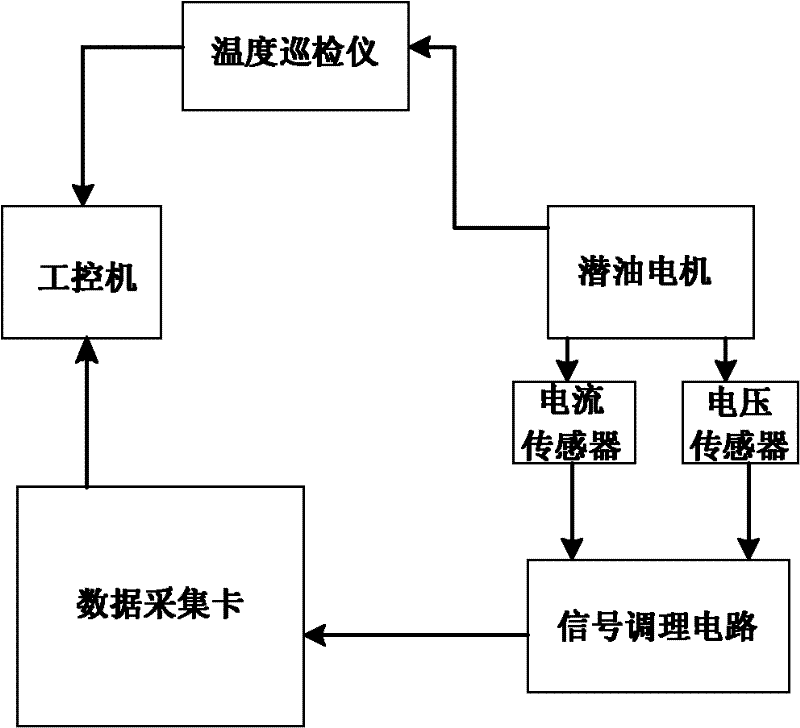

[0029] Specific implementation mode one: the following combination Figure 1 to Figure 13 Describe this implementation mode, this implementation mode comprises the following steps:

[0030] Step 1: collecting the three-phase stator voltage and three-phase stator current of the submersible motor;

[0031] Step 2: respectively process the three-phase stator voltage and the three-phase stator current through the signal conditioning circuit, and use the processed signals as the stator original current input signal and the stator original voltage input signal;

[0032] Step 3: Calculate the total calorific value u of the submersible motor by using the industrial computer according to the stator original current input signal and the stator original voltage input signal;

[0033] Step 4: in the industrial computer, distribute the total heating value u of the submersible motor to the components of the submersible motor according to the geometric dimensions and energy consumption rati...

specific Embodiment approach 2

[0042] Specific implementation mode two: the following combination Figure 12 and Figure 13 Illustrate this embodiment, this embodiment is the further explanation to embodiment one, adopt industrial computer in step 3 to calculate the total calorific value u of submersible motor according to stator original current input signal and stator original voltage input signal as follows: The total calorific value u of the submersible motor is the iron loss W i , stator copper loss W s and rotor copper loss W r and its expression is u=W i +W s +W r ,

[0043] W i = [ 1 cR m - R d cX m ( X m + 2 ...

specific Embodiment approach 3

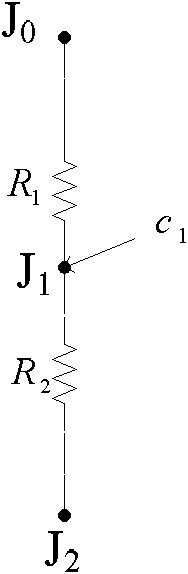

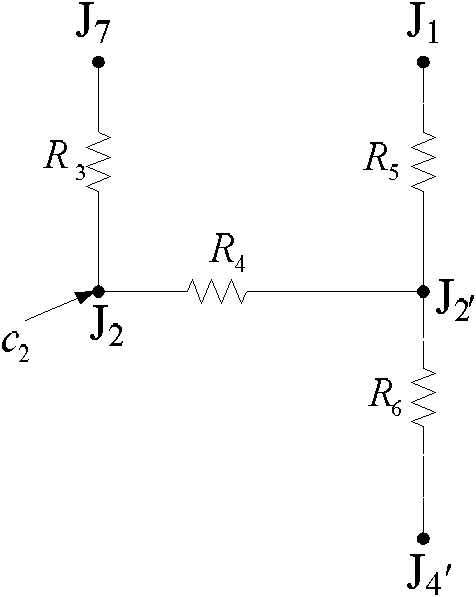

[0050] Specific implementation mode three: the following combination Figure 2 to Figure 11 Describe this embodiment, this embodiment is the further explanation to Embodiment 2, the equivalent circuit of each part of submersible motor described in step 4 is to simulate and reduce the thermal convection and thermal contact resistance of its various parts,

[0051] 41): Calculate the thermal contact resistance of the base as the resistance R 1 and R 2 consists of a resistor network in which resistor R 1 and R 2 in series at node J 0 and J 2 Between, R 1 and R 2 The connection point of is node J 1 , R 1 Obtained for direct measurement,

[0052] R 2 = 1 π h c Lr 1 ,

[0053] where h c is the contact coefficient between the base and the iron core, L is the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com