Porous electric brush

A technology of porous brushes and brushes, which is applied to circuits, current collectors, electrical components, etc., can solve the problems of increased heat generation of electric brushes, electric brushes, and shortened service life of the whole machine, so as to suppress the increase of discharge sparks, The effect of suppressing discharge arcs and reducing galvanic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

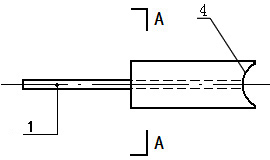

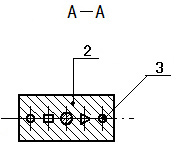

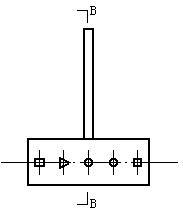

[0060] As attached figure 1 , 2 , 3, 4, the present invention includes a brush body 2 and a wire 1 fixedly connected to the brush body 2, characterized in that the brush body 2 is provided with a through hole 3, the through hole 3 is a through hole The arc bottom surface 4 of the brush body 2 and the connecting holes on the opposite surface thereof. The brush body 2 is provided with 1-20 through holes 3. The cross-sectional shape of the through hole 3 is a circle, an ellipse, a triangle, a quadrilateral, a pentagon, and a hexagon. The cross-sectional area of the through hole 3 is 0.5-1.5 square millimeters.

[0061] As attached figure 1 , 2 Shown as the first embodiment of the present invention, the present invention is that the wire 1 is in the vertical direction, the brush body 2 is provided with 4 circular, rectangular, triangular and elliptical cross-sectional through holes 3 For carbon graphite brushes, one brush can be provided with through holes 3 of the same shape; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com