Method for obtaining highly purified and intact soybean hypocotyls

A technology of soybean germ and soybean germ meal, which is applied in the field of preparing soybean germ oil and/or food, soybean hypocotyl, and soybean germ enrichment, and can solve the problems of excessive impurities in the germ, low germ recovery, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

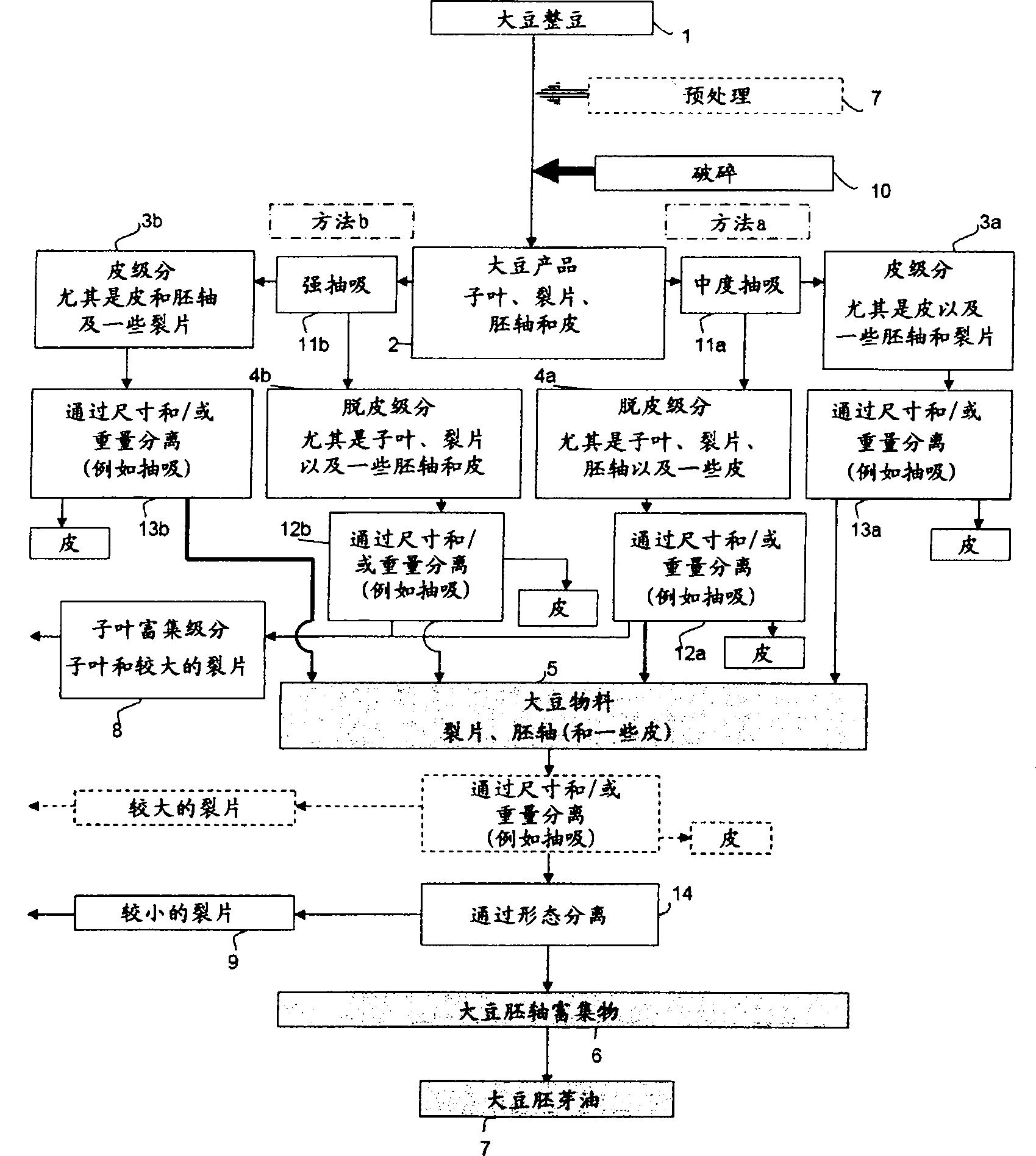

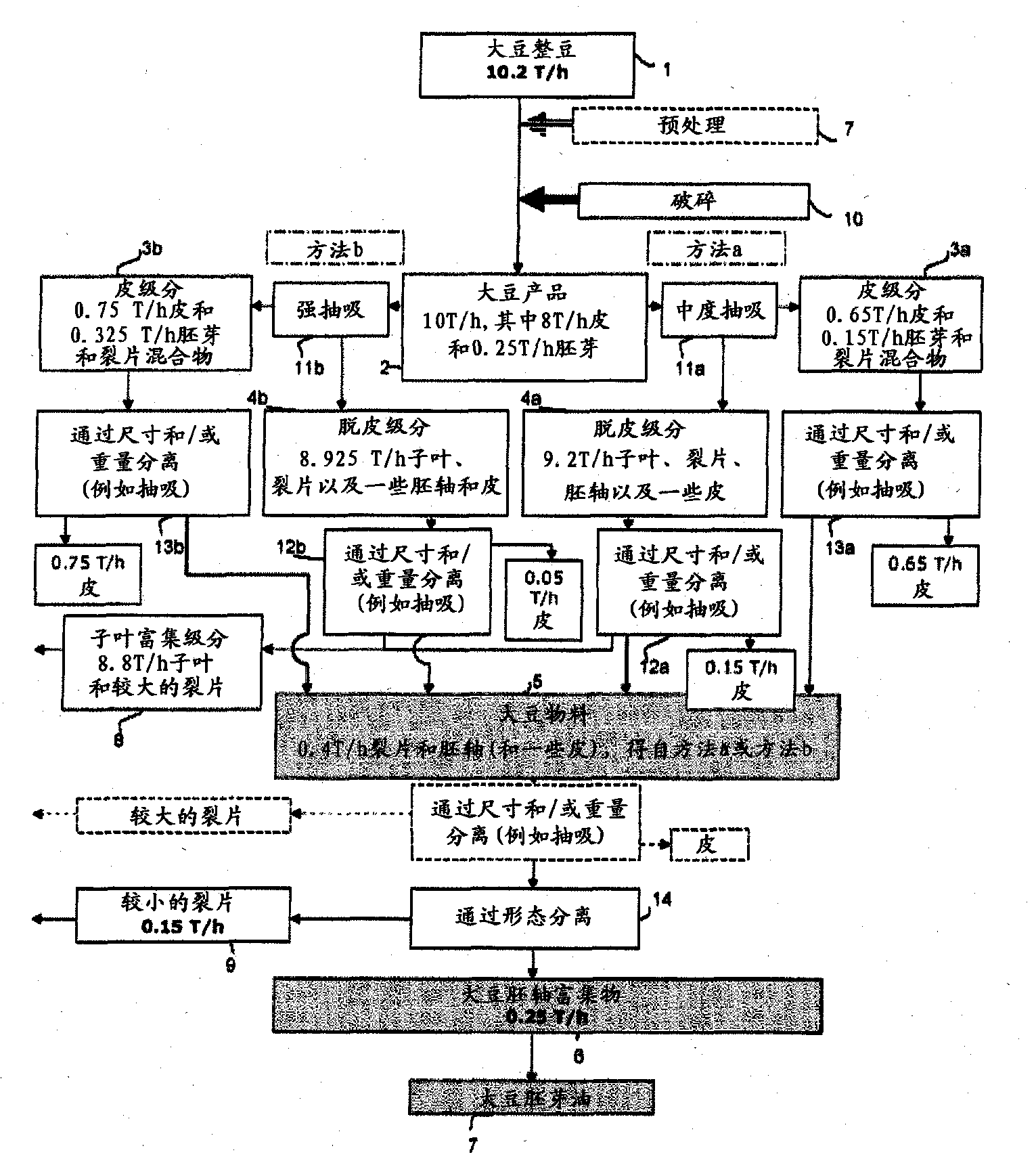

[0122] Embodiment 1: the preparation of soybean germ enrichment

[0123] This example illustrates one method of the invention.

[0124] Whole soybeans are carefully selected and impurities such as stems, stones, etc. are removed. The cleaned soybeans are then heated for 5 minutes to about 75°C and then crushed using an impact mill to about 1 / 2 the size of their original state (cotyledons or watercress formed) to obtain a mixture of skins, germs, lobes and cotyledons . The skin fraction was removed from the mixture using moderate suction (method a) to obtain a dehulled fraction producing mainly cotyledons, lobes and germ.

[0125] The dehulled fraction was further enriched in smaller lobes and germs by sieving the leaflets (and larger lobes) and aspirating the remaining skins. Size / weight / gravity differences were used to separate the dehulled fraction, from which a mixture of embryos and smaller lobes of approximately equal density was obtained.

[0126] A dimpled cylinde...

Embodiment 2

[0128] Embodiment 2: Preparation & composition of soybean hypocotyl oil & meal

[0129] This example illustrates the preparation & composition of soybean germ oil. The soybean germ oil is hexane or supercritical CO 2 Obtained by extracting the soybean hypocotyl enrichment in Example 1.

[0130] Soybean germ oil extracted from hexane contained 5.2% total phytosterols (by weight) and 21.3% linolenic acid (C18:3), based on total fatty acid weight. The oil also contains other fatty acids based on total fatty acid weight such as C16:0 (13.8%); C18:0 (3.5%); C18:1 (7.2%); C18:2 (53.5%); 0.7%). The oil also contained 2230 ppm (by weight) of total tocopherols.

[0131] Before extraction, the germ is ground to a diameter of less than 750 μm. with supercritical CO 2 (250 bar; 40°C) extracted (6h) soybean germ oil contained 7.2% total sterols (by weight) and 22.1% linolenic acid (C18:3) based on total fatty acid weight. The oil also contains other fatty acids based on total fatt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com