Original olive fruit powder and preparation method thereof

A technology for olive fruit powder and olive fruit, which is applied in powder transportation, pharmaceutical formulations, plant raw materials, etc., can solve the problems of hardening of epidermal tissue structure, large changes in product quality, loss of effective components, etc., to prevent enzymatic browning, The effect of improving palatability and reducing loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

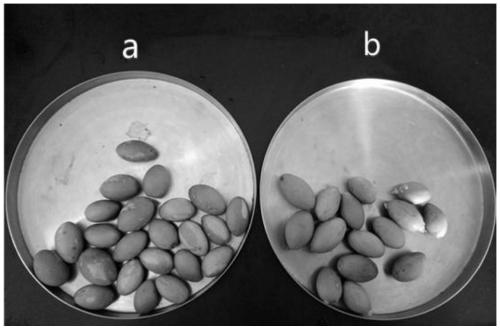

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of original flavor olive fruit powder, comprises the following steps:

[0022] The olive fruit is sequentially blanched to eliminate enzymes, vacuum freeze-dried, pitted and pulverized to obtain the original flavor olive fruit powder.

[0023] In the invention, the olive fruit is blanched to inactivate the enzyme to obtain the inactivated olive fruit. In the present invention, the blanching enzyme preferably includes boiling water blanching and warm water cooling in sequence; the temperature of the boiling water blanching is preferably 90°C to 95°C, more preferably 92°C to 95°C; the boiling water The blanching time is preferably 8s to 13s, more preferably 8s to 11s; the warm water cooling temperature is preferably 20°C to 25°C, more preferably 23°C to 25°C; the warm water cooling time is preferably 25s ~30s, more preferably 25s~27s. After the warm water is cooled, the present invention preferably drains the olive fru...

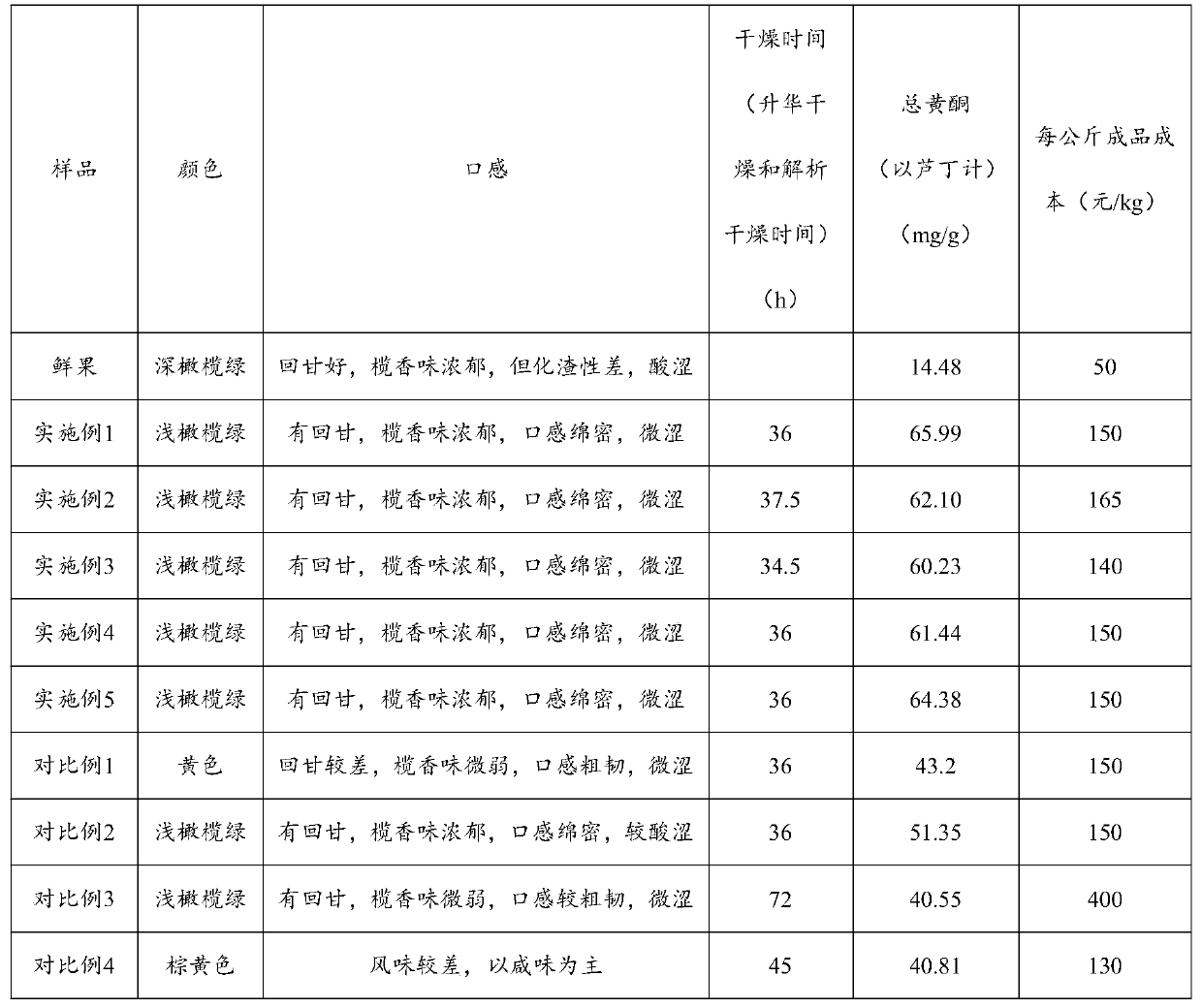

Embodiment 1

[0037] The preparation process of original flavor olive fruit powder:

[0038] (1) Select mature olive fruits with large and plump grains, smooth surface, no disease spots, no insect eyes, and yellow-green color, and wash the olive surface stains with water.

[0039] (2) After blanching the above-mentioned olive fruit in boiling water at 95°C for 10 seconds, cooling in a warm water bath at 25°C for 25 seconds, and draining naturally for 30 minutes, the enzyme-inactivated olive fruit was obtained.

[0040] (3) Place the enzyme-inactivated olive fruit in a 6°C refrigerator for precooling for 5 hours to obtain the precooled olive fruit.

[0041] (4) Turn on the vacuum freeze dryer. When the temperature of the layers reaches -33°C, arrange the pre-cooled olives in a single layer in the drying chamber. When the temperature of the layers reaches -50°C, the pre-freezing is completed.

[0042] (5) When the absolute pressure of the vacuum freeze dryer system is 80 Pa, increase the tem...

Embodiment 2

[0047] The preparation process of original flavor olive fruit powder:

[0048] (1) Select mature olive fruits with large and plump grains, smooth surface, no disease spots, no insect eyes, and yellow-green color, and wash the olive surface stains with water.

[0049] (2) After blanching the above-mentioned olive fruit in boiling water at 95°C for 10 seconds, cooling in a warm water bath at 25°C for 25 seconds, and draining naturally for 30 minutes, the enzyme-inactivated olive fruit was obtained.

[0050] (3) Place the enzyme-inactivated olive fruit in a 6°C refrigerator for precooling for 5 hours to obtain the precooled olive fruit.

[0051] (4) Turn on the vacuum freeze dryer. When the temperature of the layers reaches -33°C, arrange the pre-cooled olives in a single layer in the drying chamber. When the temperature of the layers reaches -50°C, the pre-freezing is completed.

[0052] (5) After the system absolute pressure of the vacuum freeze dryer is 80 Pa, raise the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com