Method and device for electronically grading eggs through three-dimensional lifting

A technology of a lifting device and a grading method, which is applied in poultry farming, application, animal husbandry, etc., can solve problems such as difficulty in greatly increasing output, limited production capacity, and increased damage, and achieves improved grading efficiency and accurate weighing , the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

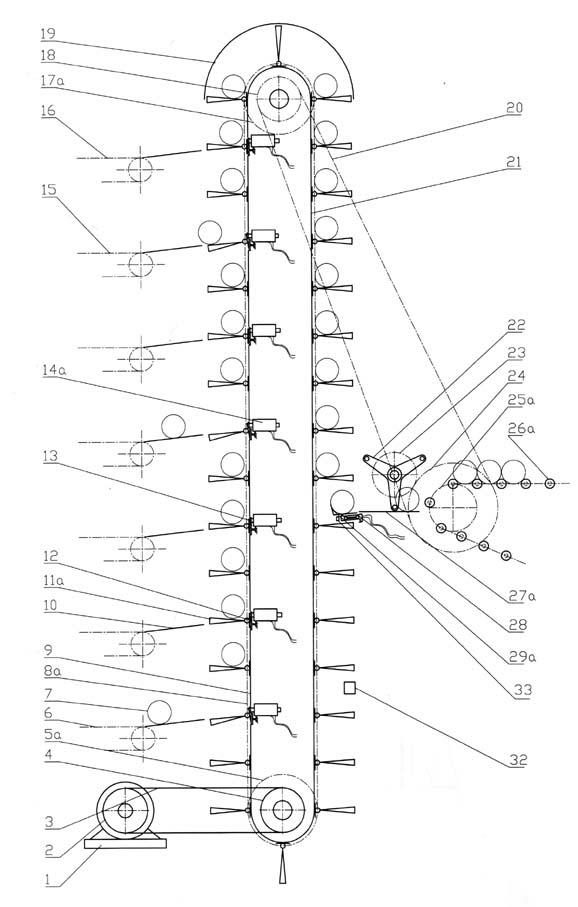

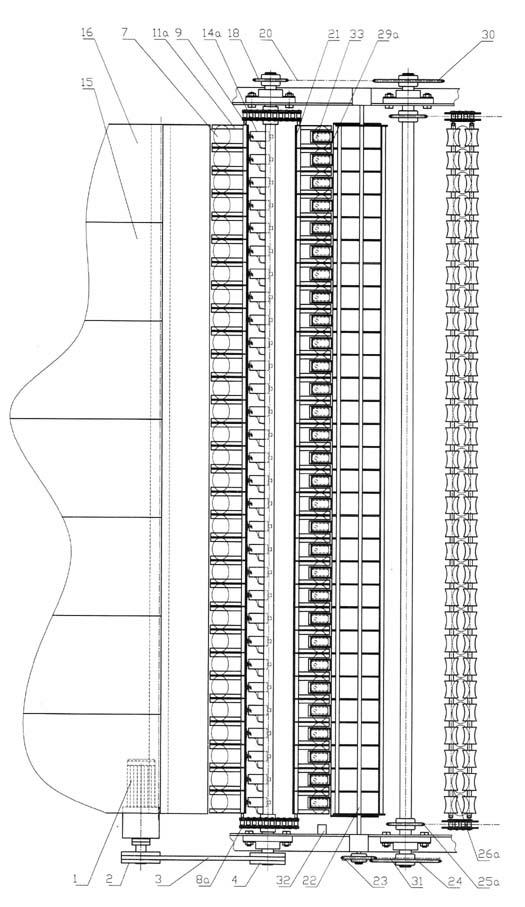

[0056] A three-dimensional lifting electronic grading device for poultry eggs, comprising a lower sprocket 5a of the three-dimensional lifting device, a chain 8a of the three-dimensional lifting device, a moving egg tray 11a on the chain, a short rod egg unloading electromagnet 14a, a chain drive driving sprocket 18, and a three-dimensional lifting Device upper sprocket 17a, weight sensor 28, fixed egg holder 29, it is characterized in that:

[0057] The motor 1 drives the V-belt driving driving pulley 2, the V-belt driving driving pulley 2 is connected with the V-belt driving driven pulley 4 through the V-belt 3, the V-belt driving driven pulley 4 drives the lower sprocket 5a of the three-dimensional lifting device, and the lower three-dimensional lifting device Sprocket 5a is connected with sprocket wheel 17a on the three-dimensional elevating device chain 8a by three-dimensional elevating device, and casing 19 is installed just above sprocket wheel 17a on the three-dimension...

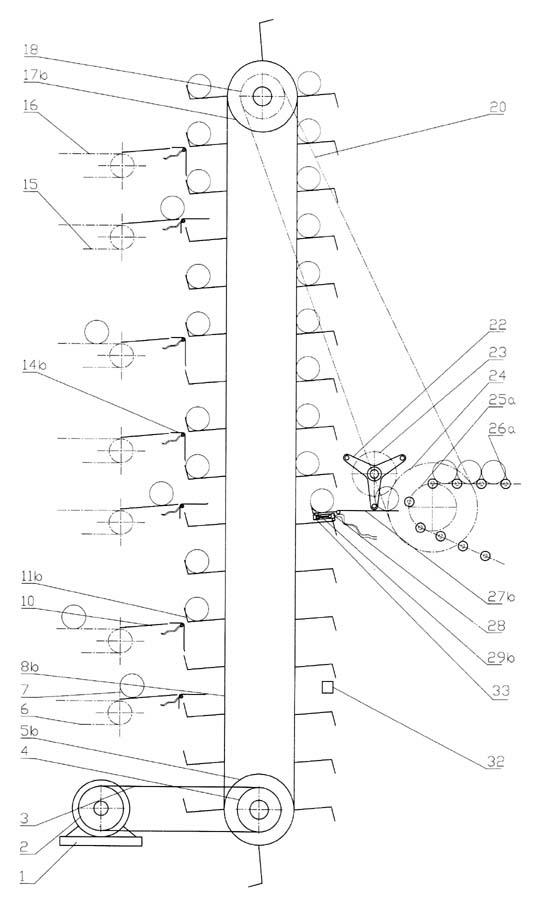

Embodiment 2

[0071] This embodiment makes the following changes on the basis of Embodiment 1:

[0072] The lower sprocket 5a of the three-dimensional lifting device can also be the lower pulley 5b of the three-dimensional lifting device.

[0073] The three-dimensional lifting device chain 8a can also be a three-dimensional lifting device flat belt 8b.

[0074] The moving egg holder 11a on the chain can also be the moving egg holder 11b on the belt.

[0075] The short rod unloading electromagnet 14a can also be a rotating egg unloading electromagnet 14b.

[0076] The upper sprocket 17a of the three-dimensional lifting device can also be the upper pulley 17b of the three-dimensional lifting device.

[0077] The feeding guide plate 27a can also be a hinged feeding guide plate 27b, and the fixed egg tray 29a can also be a hinged fixed egg tray 29b, and the two are connected by a hinge.

[0078]In this embodiment, the three-dimensional elevating device flat belt 8b is used for lifting, and t...

Embodiment 3

[0080] This embodiment makes the following changes on the basis of the foregoing two embodiments:

[0081] The rotating egg unloading electromagnet 14b can also be a long pole egg unloading electromagnet 14c.

[0082] The feeding device sprocket 25a can also be a feeding device pulley 25b.

[0083] The egg support roller 26a of the feeding device can also be a flat belt 26b of the feeding device.

[0084] Said feeding guide plate 27a can also be an extended feeding guide plate 27c.

[0085] In the present embodiment: use the long rod discharge electromagnet 14c, when the stop bar of the long rod discharge electromagnet 14c stretches out, it is in the hollow position of the two egg holder sides of the movable egg holder 11b on each belt, and stretches into the belt 40-80mm in the moving egg holder 11b, there is a 2-10mm gap from the moving egg holder 11b head on the belt when retracting, and the fixed egg holder 29a is completely fixed on the weight sensor 28. The feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com