Combined hydraulic power cavitation device

A technology of hydraulic cavitators and pipelines, which is applied to fluid mixers, chemical instruments and methods, mixers, etc., can solve the problems that a single orifice plate cannot meet actual needs, and achieve improved energy utilization efficiency, simple structure, The effect of cavitation effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

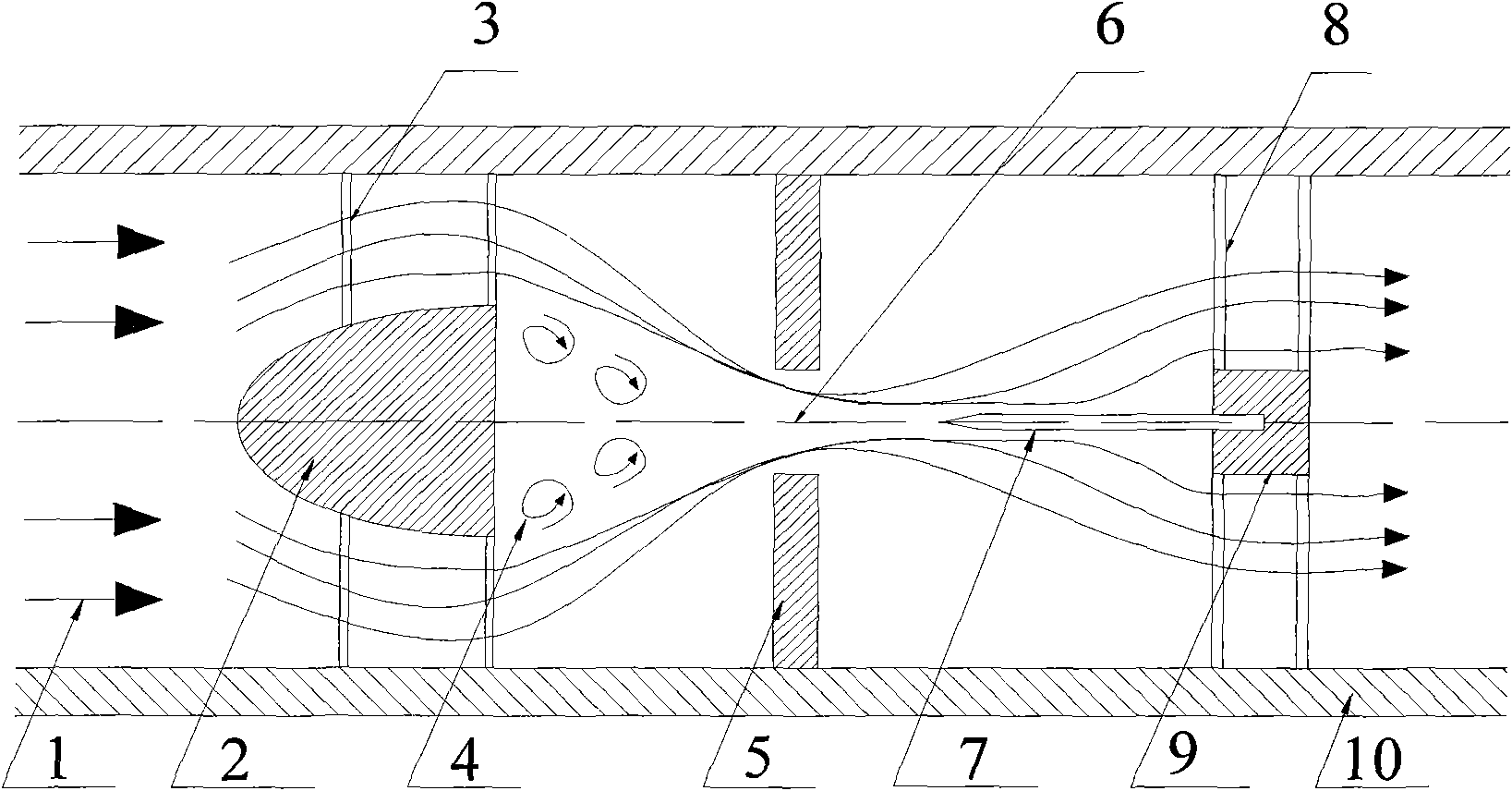

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

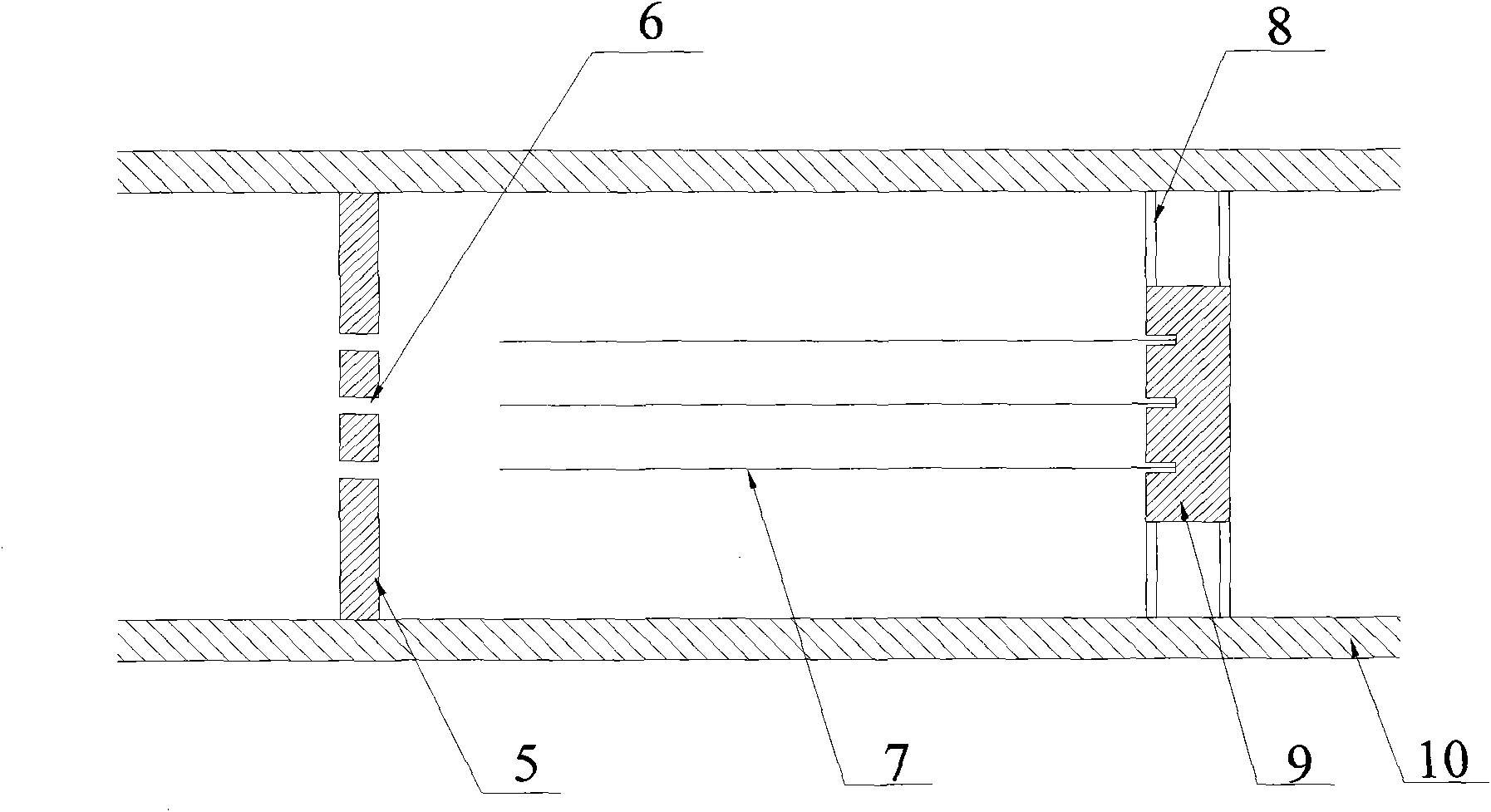

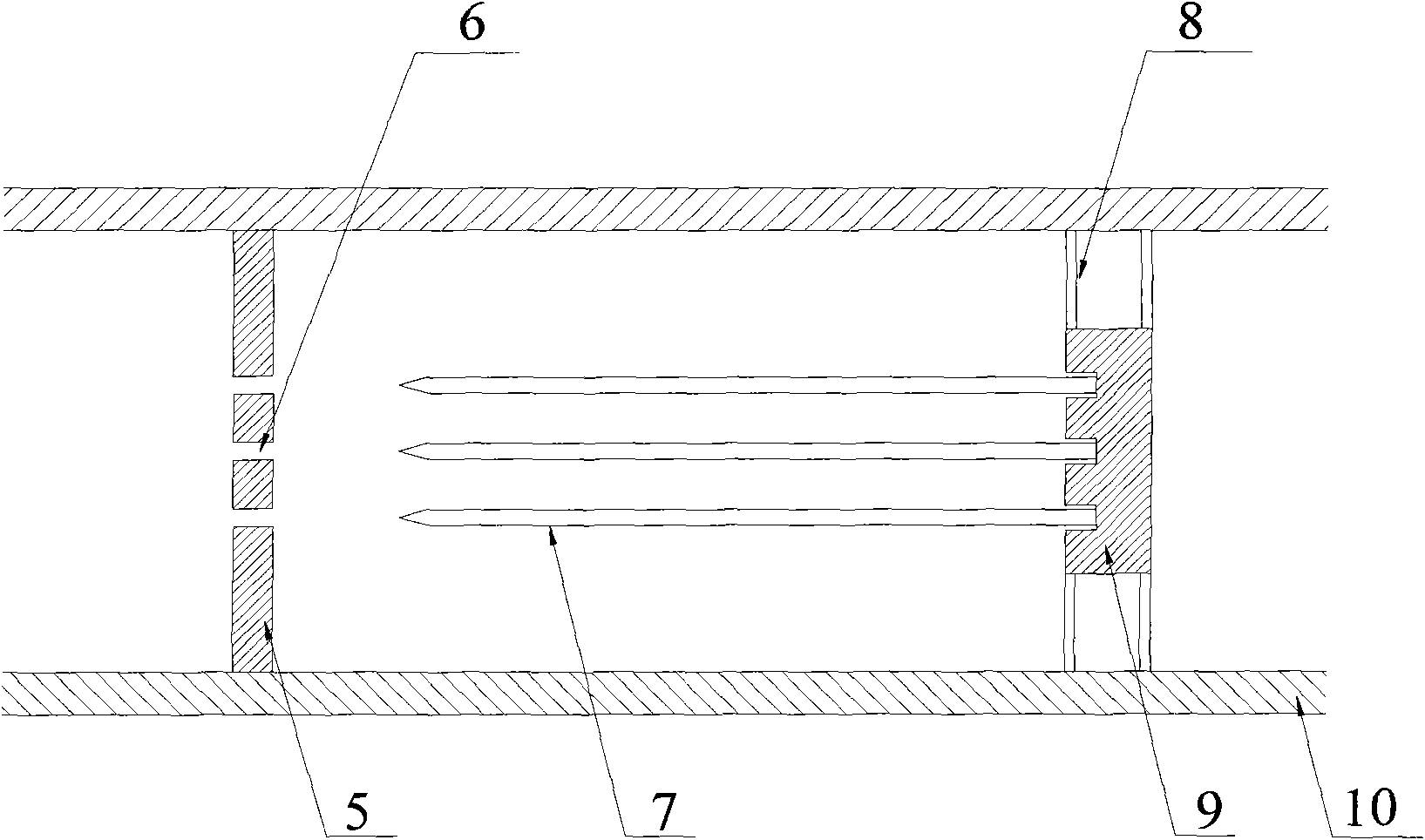

[0026] see figure 1 , this embodiment includes submerged body 2, orifice plate 5 and reed 7. The submerged body 2 is provided with a submerged body fixing bracket 3 welded and fixed to the circular pipe 10, and when the liquid medium flows through the submerged body 2, wake cavitation is formed. The orifice plate 5 is provided with jet inflow holes 6, and the orifice plate 5 can be fixed in the circular pipe 10 by means of welding, flanges, nuts, etc., and the liquid medium flows through the jet inflow holes 6 to form jet hydraulic cavitation. The reed 7 is embedded in the axial slit of the reed fixing base 9 and welded and fixed in the circular pipe 10 through the reed fixing bracket 8. The tip of the reed 10 is facing the center of the injection hole 6, and the There is spacing. The liquid medium sprayed from the injection hole 6 impacts the tip of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com