LED chip jointing device

A technology of LED chips and bonding devices, applied in the direction of electrical components, electrical components, circuits, etc., can solve the problems of delaying production time, undisclosed structure, reducing productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

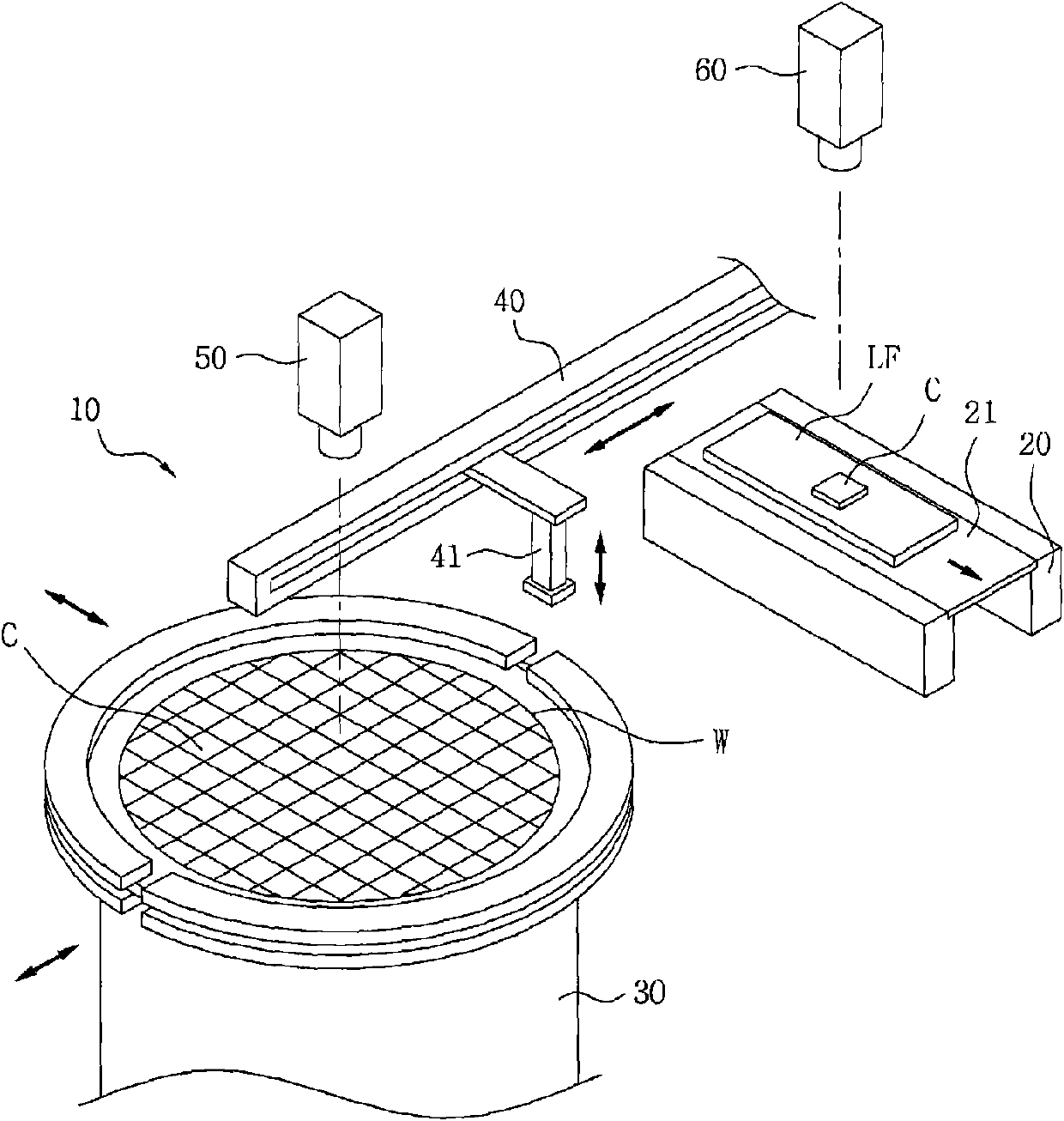

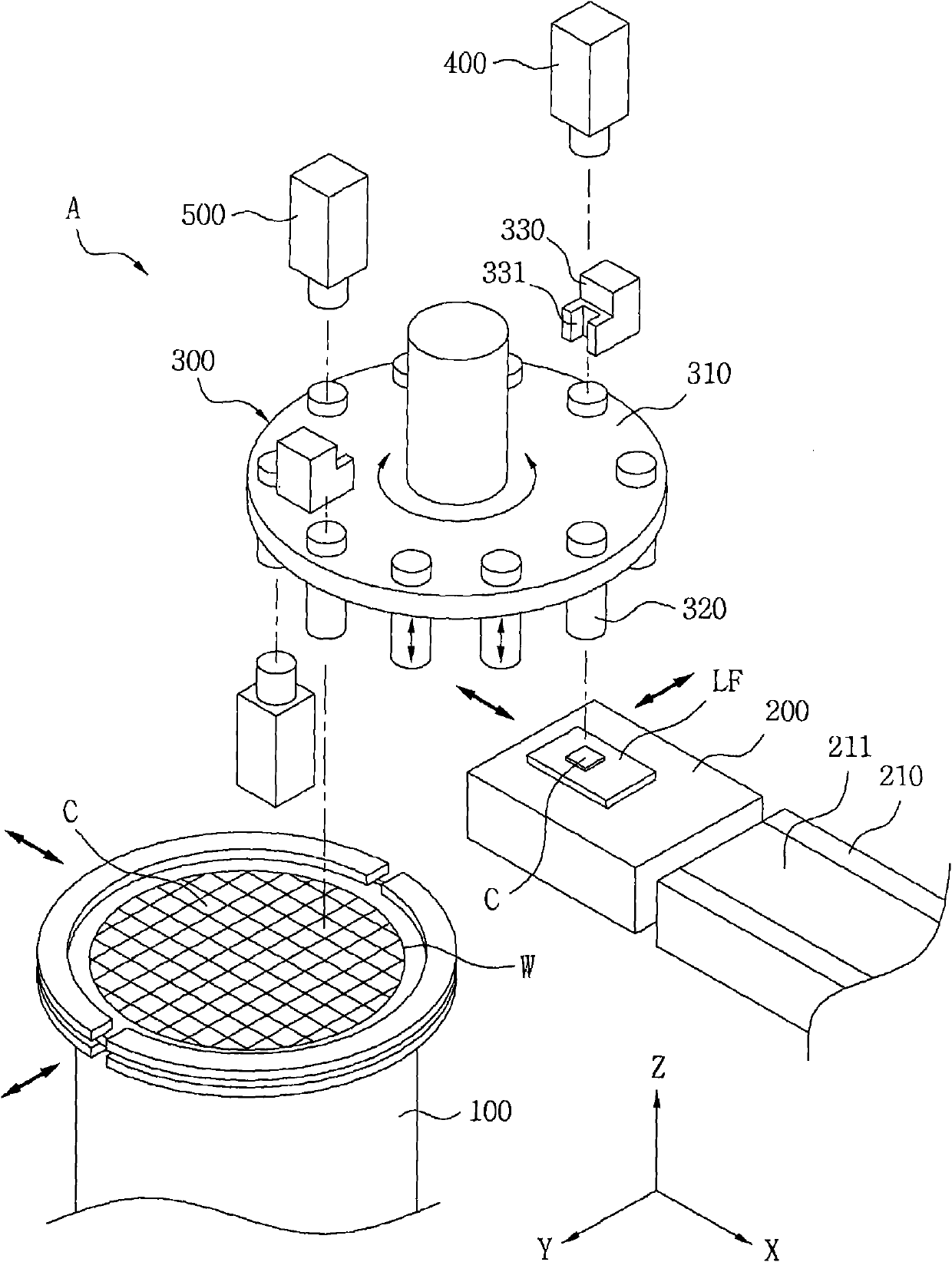

[0033] figure 2 is a perspective view illustrating the LED chip bonding apparatus according to the first embodiment of the present invention. image 3 Yes figure 2 Schematic diagram of the LED chip bonding setup. Figure 4 is icon figure 2 A perspective view of another example of the main body.

[0034] like figure 2 and image 3 As shown, the LED chip bonding apparatus A according to the first embodiment of the present invention includes: a wafer holder 100 on which a wafer W having an LED chip C is installed, and it can be arranged along a plane perpendicular to each other along axes (hereinafter referred to as For "X-axis" and "Y-axis") movement; lead frame holder 200, on which lead frame LF is positioned, and which can move along two orthogonal axes on a plane parallel to the plane on which the wafer holder moves; LED chip transfer unit 300, which can rotate around an axis (hereinafter referred to as "Z axis") perpendicular to the plane where the wafer carrier mo...

Embodiment approach 2

[0061] Figure 5 is a perspective view illustrating an LED chip bonding apparatus according to a second embodiment of the present invention.

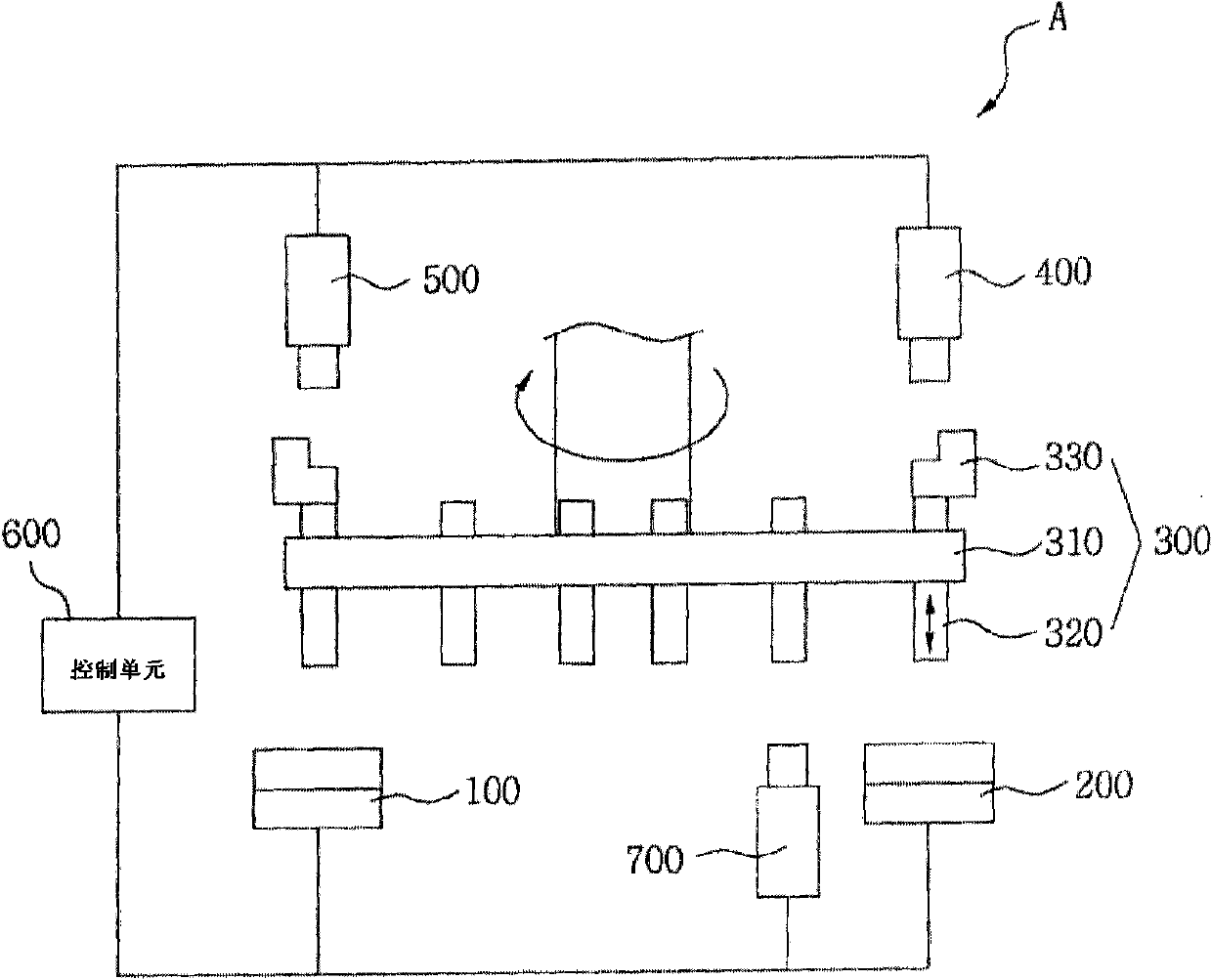

[0062] like Figure 5 As shown, the LED chip bonding apparatus A' according to the second embodiment of the present invention includes: a wafer holder 100; a lead frame holder 200; the LED chip transfer unit 300 ′; the first vision unit 400 configured to recognize the position information of the lead frame LF and the second vision unit 500 configured to recognize the position information or setting state of the LED chip C; and the control unit 600 .

[0063] The LED chip transfer unit 300' includes: a main body 310' movable along the Z axis and rotatable around the Z axis; and a plurality of head devices 320' attached to the circumference of the main body 310' at equal intervals.

[0064] The main body 310' itself is moved in the Z-axis direction by a pressing unit such as a pneumatic cylinder or a hydraulic cylinder.

[0065] As des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com