Valve having a long average operating life

A valve body and seat technology, applied in the field of valves with high average operating life, can solve problems such as malfunction, shortened maintenance intervals, valve seals that are difficult to meet firmness or life, and achieve the effect of improving flexibility and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following figures, the same reference numerals denote the same or the same type of components.

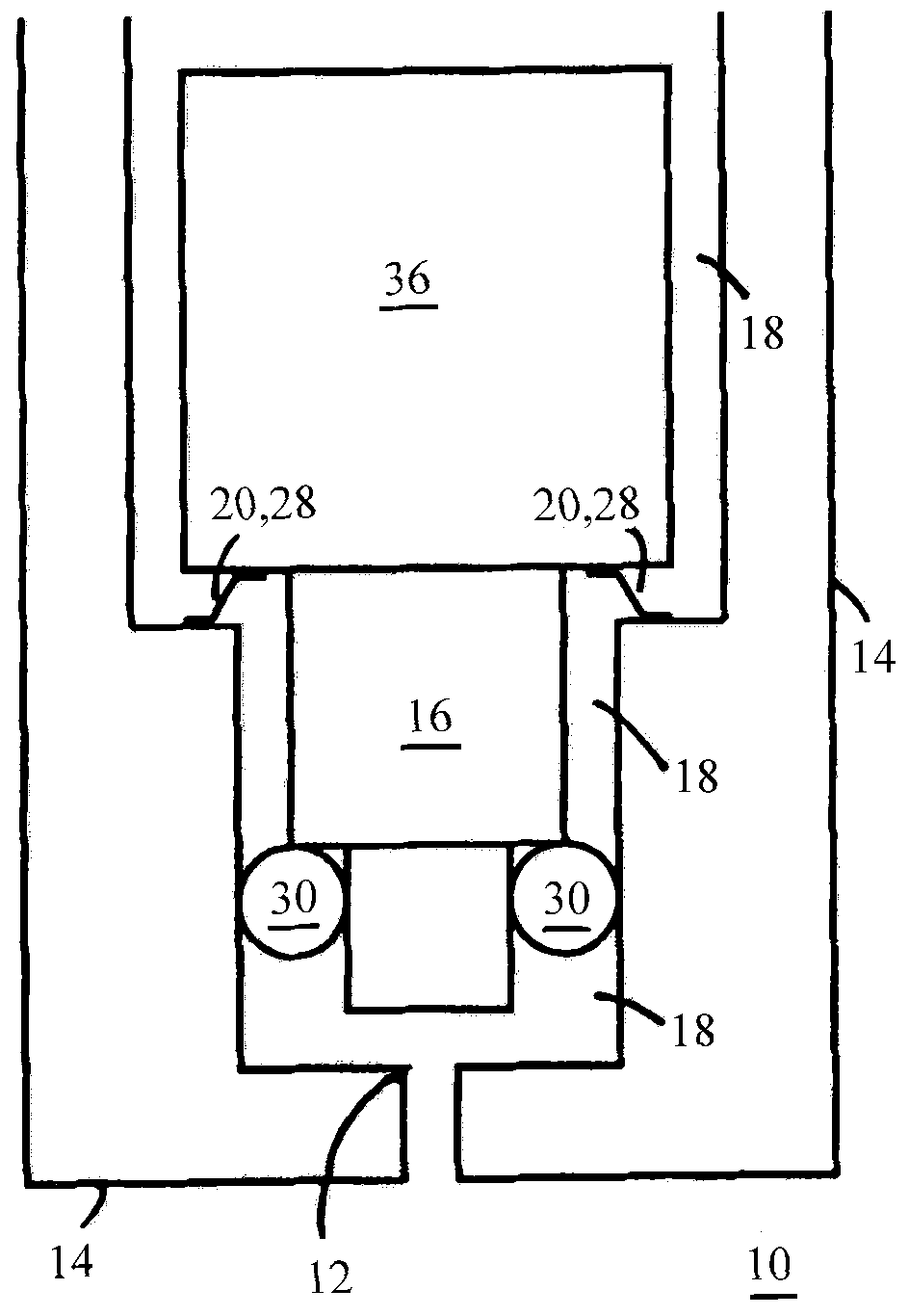

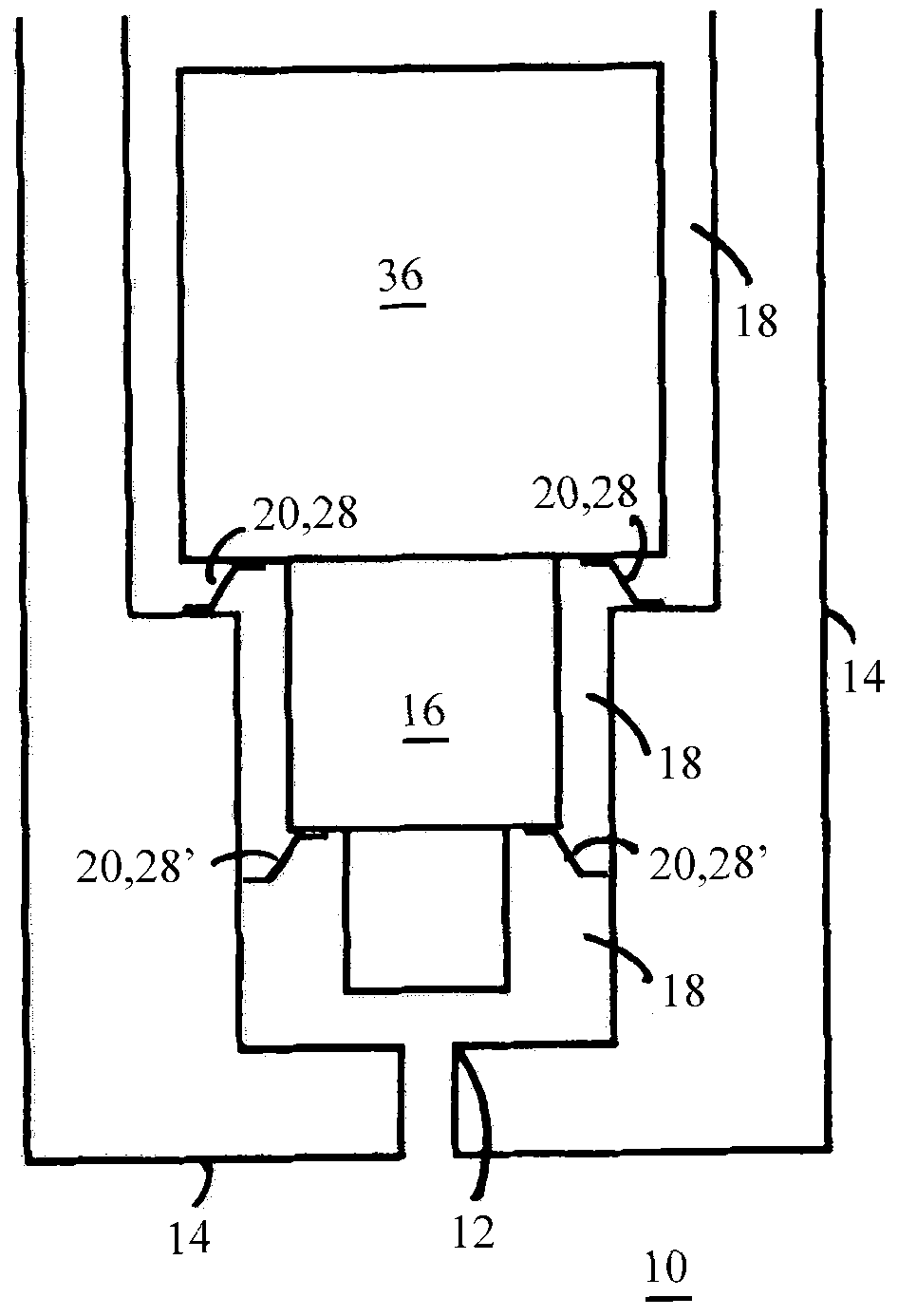

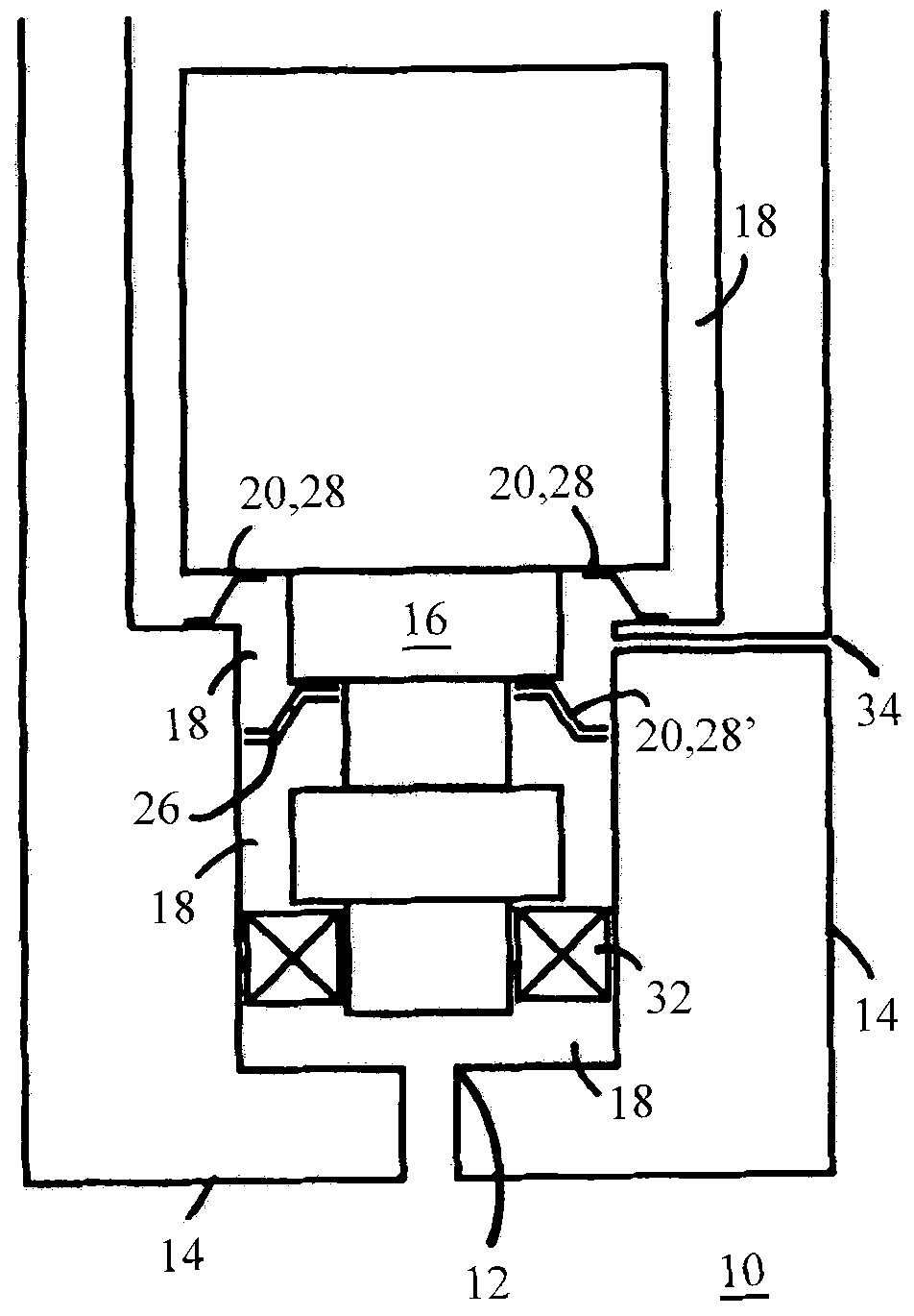

[0024] figure 1 A first embodiment of the valve according to the invention is shown. The illustrated valve 10 comprises a valve housing 14 with a valve seat 12 , wherein a valve body 16 is located inside the valve housing 14 , which is movable relative to the valve housing 14 . The upper part of the movable valve body is designed as an electromagnetic actuation device 36 . The electromagnetic actuating device 36 can be designed, for example, as a simple permanent magnet and exerts a force for moving the valve body 16 by energizing a coil winding, not shown, arranged on the valve housing 14 . A space 18 is formed between the valve body 16 and the valve housing 14 , which is divided into regions by the seal 20 and the O-ring 30 at the sealing point 28 . The O-ring 30 can generally be made of an elastomer material here. The seal 20 arranged at the sealing point 28 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com