Novel manufacturing technology for cloth shoes

A manufacturing process and technology of cloth shoes, which is applied to uppers, footwear, soles, etc., can solve problems such as non-wear resistance, unreasonable sole shape, and unhelpful body shape, and achieve the effects of reducing production costs, huge market potential, and environmental protection.

Inactive Publication Date: 2011-06-15

何党生

View PDF4 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its shortcomings are manifested in the following five aspects: 1. The style is traditional and old, and the variety is single and unchanged.

2 Flat heel or small heel difference, unreasonable sole shape, uncomfortable feeling on heel and calf after wearing, long-term wearing is not beneficial to body shape

3Because of the internal turning last process, the finished shoes have the disadvantages of not being crisp, easy to deform, and difficult to match with modern clothing

4. The sole is very easy to absorb water, not resistant to dirt, not wear-resistant, and the suitable range is small

5 Handmade shoes with soles, the error of shoes is large due to individual differences, and the shoe size is not standard

In short, this kind of cloth shoes are fashionable in style and have a wide variety, which is commendable. But in another sense, the selection of materials for this kind of cloth shoes has deviated from the category of cloth shoes, and only pursues style and appearance while ignoring the inner quality. The comfort and the healthy breathability of the required materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

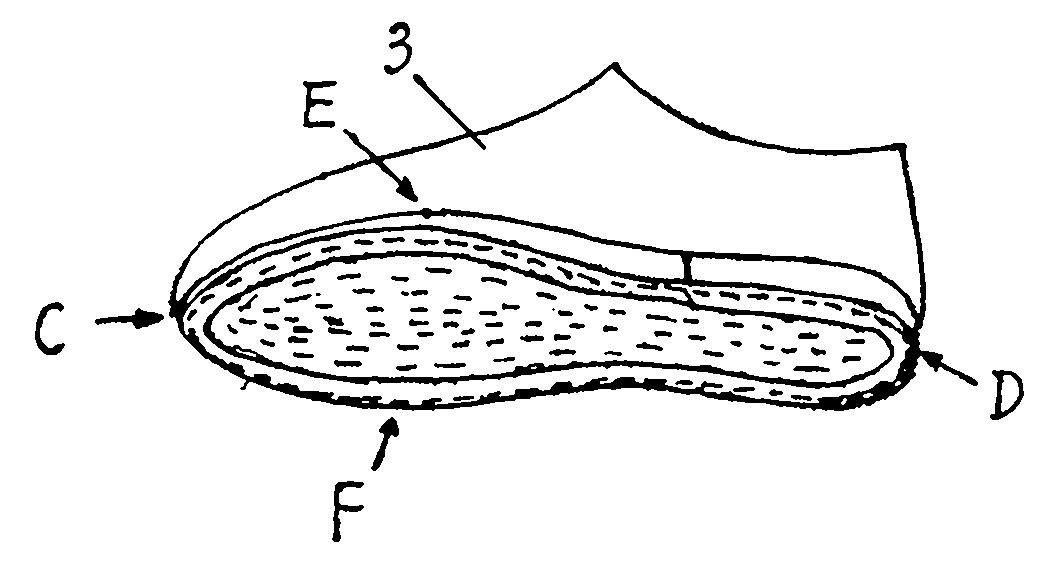

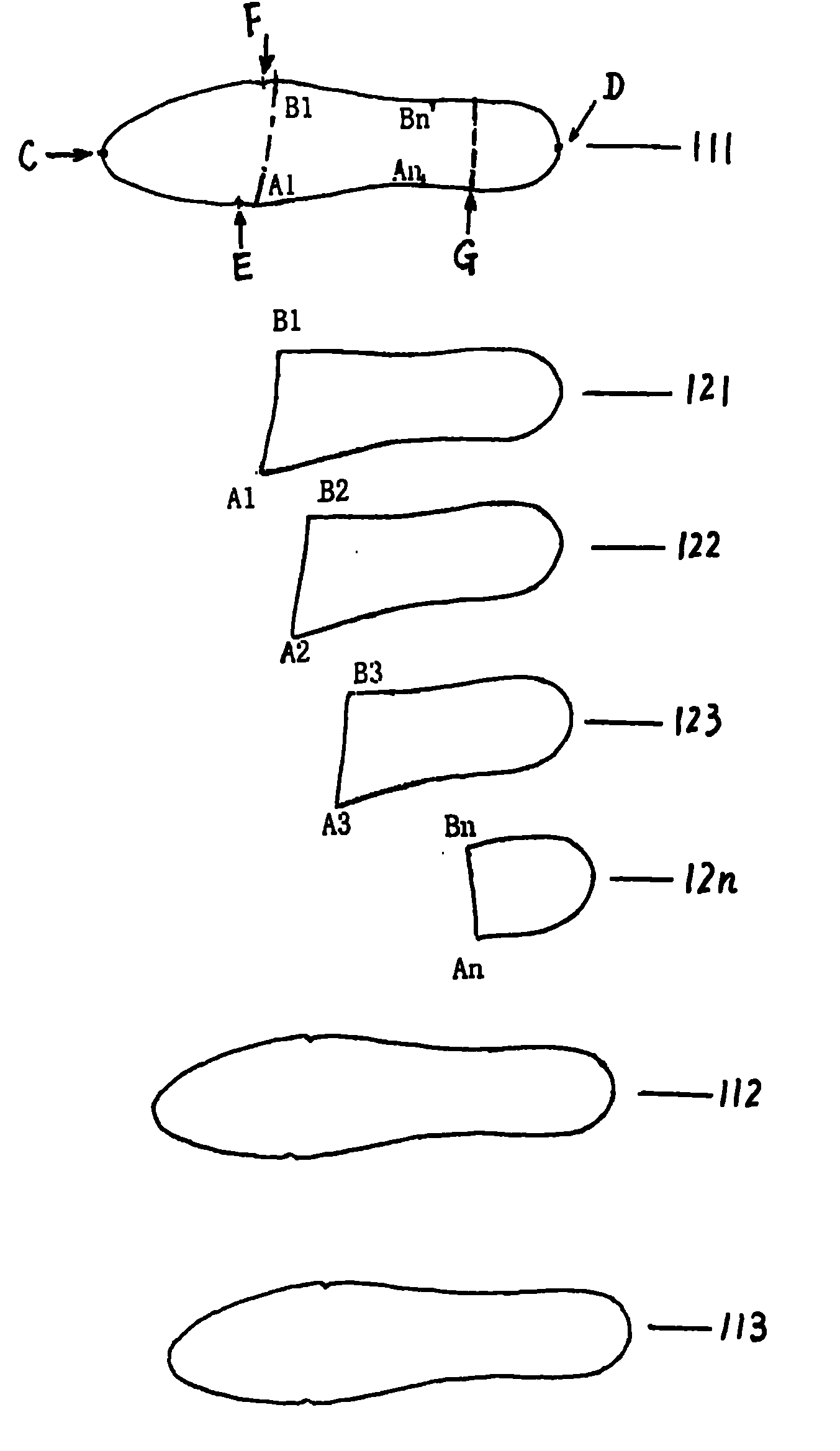

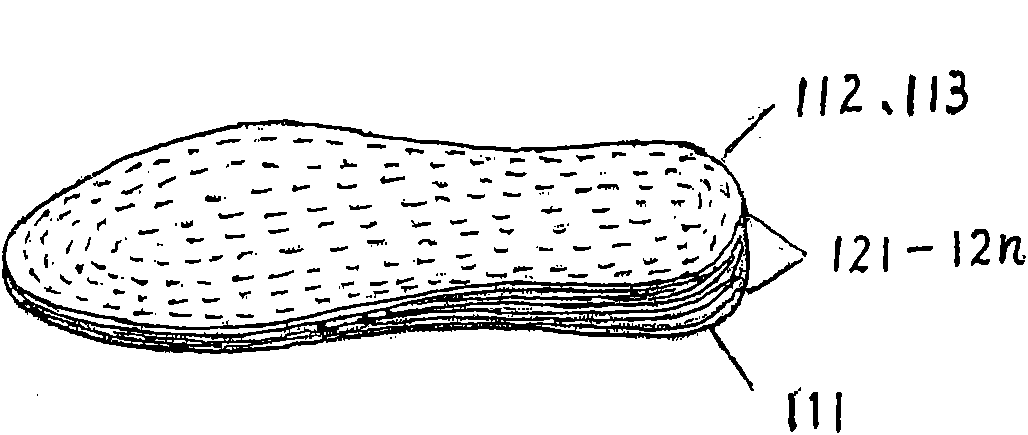

The invention relates to a production technology for cloth shoes. The production technology for the cloth shoes comprises the following steps of: sequentially superposing and sewing whole sheets and half sheets which are needed for manufacturing an outsole to make a blank of the outsole, wrapping the edge of the outsole with a wrapping band, and bonding by using glue to obtain a finished product of the outsole; sewing an insole sheet and a midsole together to obtain a composite insole; then mating the front face of the prepared insole with a shoe tree and fixing, lasting a prepared upper, and drying and setting or storing for one to two days in a dry state; removing the shoe tree to obtain a shoe body; then aligning the shoe body with the outsole, and sewing the shoe body and the outsole or directly bonding the shoe body and the outsole by using the glue to obtain a semi-finished shoe; and finally, brushing the glue on an antiskid sheet and a sole of the semi-finished shoe with the shoe tree respectively, heating and drying and bonding by pressure, and cooling and then removing the shoe tree to obtain a cloth shoe. The production of the cloth shoe is more labor-saving than the conventional cloth shoe, the labor force is saved, the production cost is also reduced, and suitable crowd is enlarged. The product technology is a high-quality environment-friendly project with huge market potential and infinite broad prospect.

Description

A new technique for making cloth shoes technical field The invention relates to a cloth shoe and a production process, in particular to the preparation of a cloth shoe sole, the shoe body and the combined sewing process, belonging to the technical category of cloth shoe production. Background technique As we all know, there are several types of cloth shoes on the market. One is the handmade cloth shoes with soles represented by traditional crafts. Its advantages are light and comfortable to wear because the soles are of a thousand-layer structure, and they are healthy and healthy for the feet. Its shortcomings are manifested in the following five aspects: 1. The style is traditional and old, the variety is single and unchanged, and it is the same for a century, which cannot satisfy people's psychology of pursuing fashion. 2 Flat heel or small heel difference, unreasonable sole shape, uncomfortable feeling on heel and calf after wearing, long-term wearing is not beneficial...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A43B9/02A43B13/02A43B23/02A43D8/00A43D11/00A43D25/00A43D95/10

Inventor 何党生

Owner 何党生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com