Heatless regenerative adsorption dryer

An adsorption drying and heatless regeneration technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as high consumption of regeneration gas and energy, impact on service life, and lack of recovery of desiccant surface activity. , to achieve the effect of reducing exhaust gas emission, reducing energy waste and improving drying efficiency

Inactive Publication Date: 2011-06-15

江苏德厚机电有限公司

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the phenomenon of "incomplete regeneration" occurs in the regeneration stage, the surface activity of the desiccant will not recover to the original level, which will affect the outlet dew point of the treated compressed air, and the accumulation of residual moisture in the desiccant will affect its service life

Therefore, in order to avoid "incomplete regeneration", the existing heatless regenerative adsorption dryer will increase the regeneration gas consumption as much as possible to meet the complete regeneration of the desiccant, which leads to excessive consumption of regeneration gas and energy, but if the regeneration gas is reduced "Incomplete regeneration" will seriously affect the efficiency of the dryer and the service life of the desiccant

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

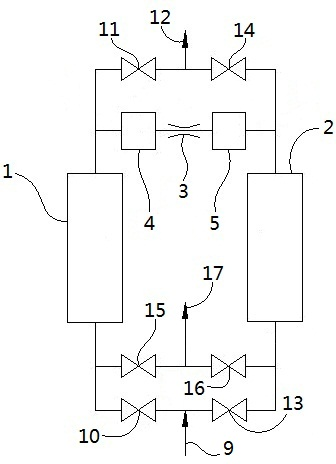

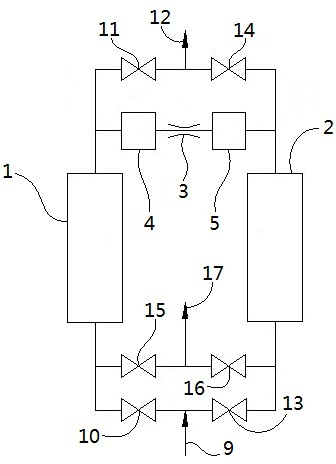

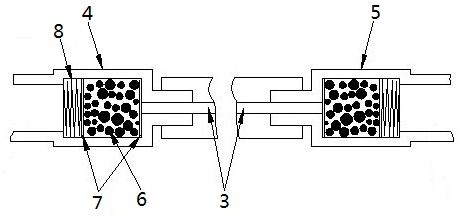

The invention discloses a heatless regenerative adsorption dryer. Based on the prior art, a first drying tank and a second drying tank are increased in the dryer, wherein the first drying tank is arranged at any position between a first drying tower and a regenerative gas passage, the second drying tank is arranged at any position between a second drying tower and the regenerative gas passage, and an adsorbent is filled in the first drying tank and the second drying tank; and porous plates arranged on two sides of the adsorbent and a waveform spring for fully compacting the adsorbent between the porous plates are arranged in the first drying tank and the second drying tank respectively. The heatless regenerative adsorption dryer provided by the invention reduces regenerative gas consumption at the same time of improving the dryness of the regenerative gas through the first drying tank and the second drying tank, reduces the waste of energy and the emission of waste gas, and improves the drying efficiency.

Description

A heatless regenerative adsorption dryer technical field The invention relates to a gas drying device, in particular to a heatless regenerative adsorption dryer. Background technique The heatless regenerative adsorption dryer utilizes the principle of pressure swing adsorption to remove moisture from compressed gas. The current structure of the dryer is a double-tower type, and the drying tower and the regeneration tower work alternately and reciprocally to achieve the purpose of drying. Its working cycle is divided into two stages of adsorption and regeneration: in the drying stage, the pressure of the drying tower increases, and the partial pressure of water vapor in the air also increases accordingly. When passing through the desiccant bed, the water vapor is absorbed by the desiccant, making the desiccant The partial pressure of water vapor on the surface gradually increases and reaches equilibrium, so that the compressed air is dried; during the regeneration stage, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/26B01D53/04

Inventor 周家伦陈小宝白鑑张松刘海伟

Owner 江苏德厚机电有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com