Differential-height casting method for horizontal roll frame blank of rough mill

A technology of horizontal roll and rough rolling mill, which is applied in the casting of castings and the differential height casting of the blank of the horizontal roll stand of the rough rolling mill, can solve the waste of resources, increase the production cost and pollutant discharge, increase the total weight of molten steel, energy and energy consumption. Raw materials and other issues, to achieve the effect of saving the total production cost, reducing the total weight of molten steel, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

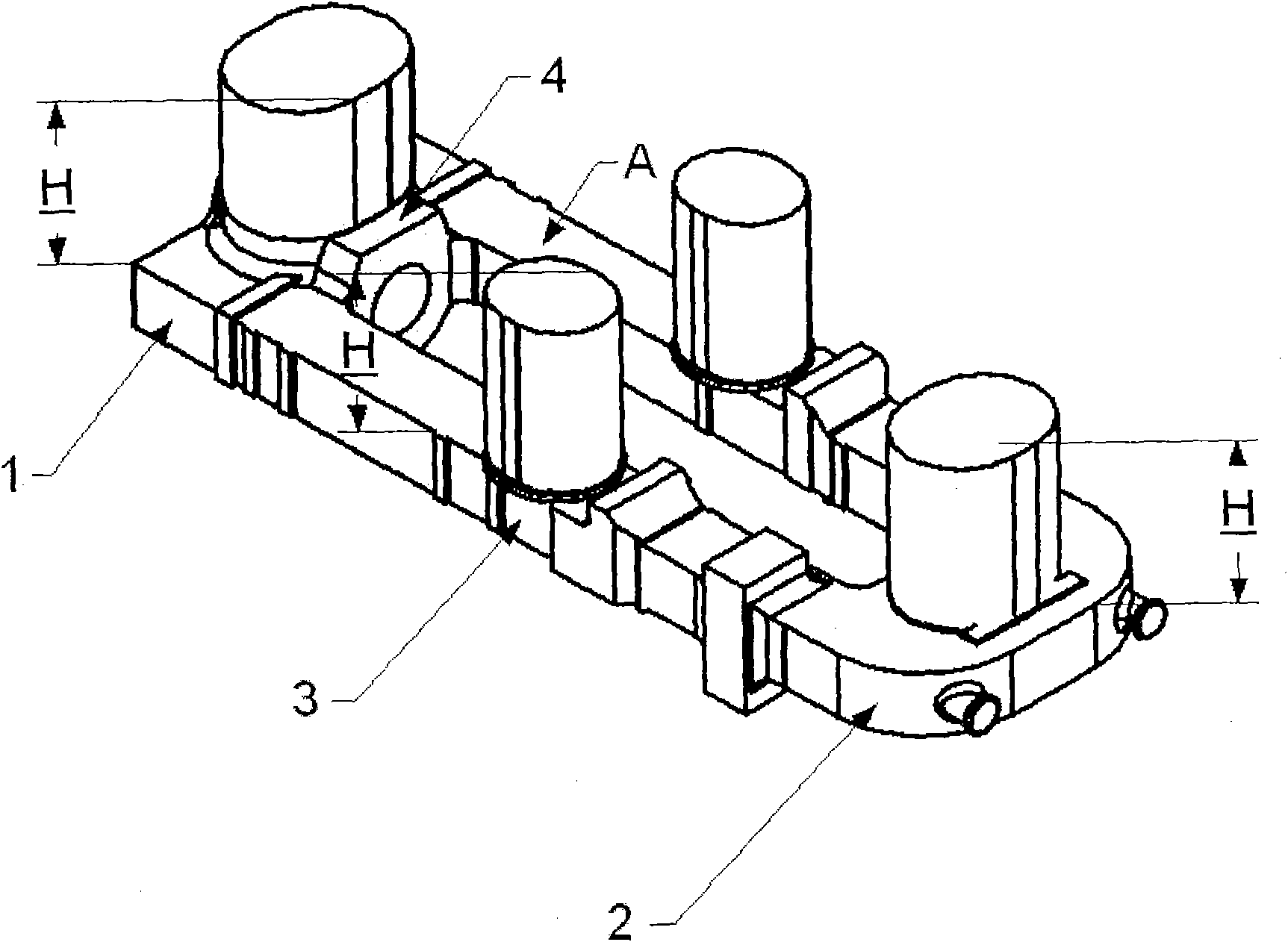

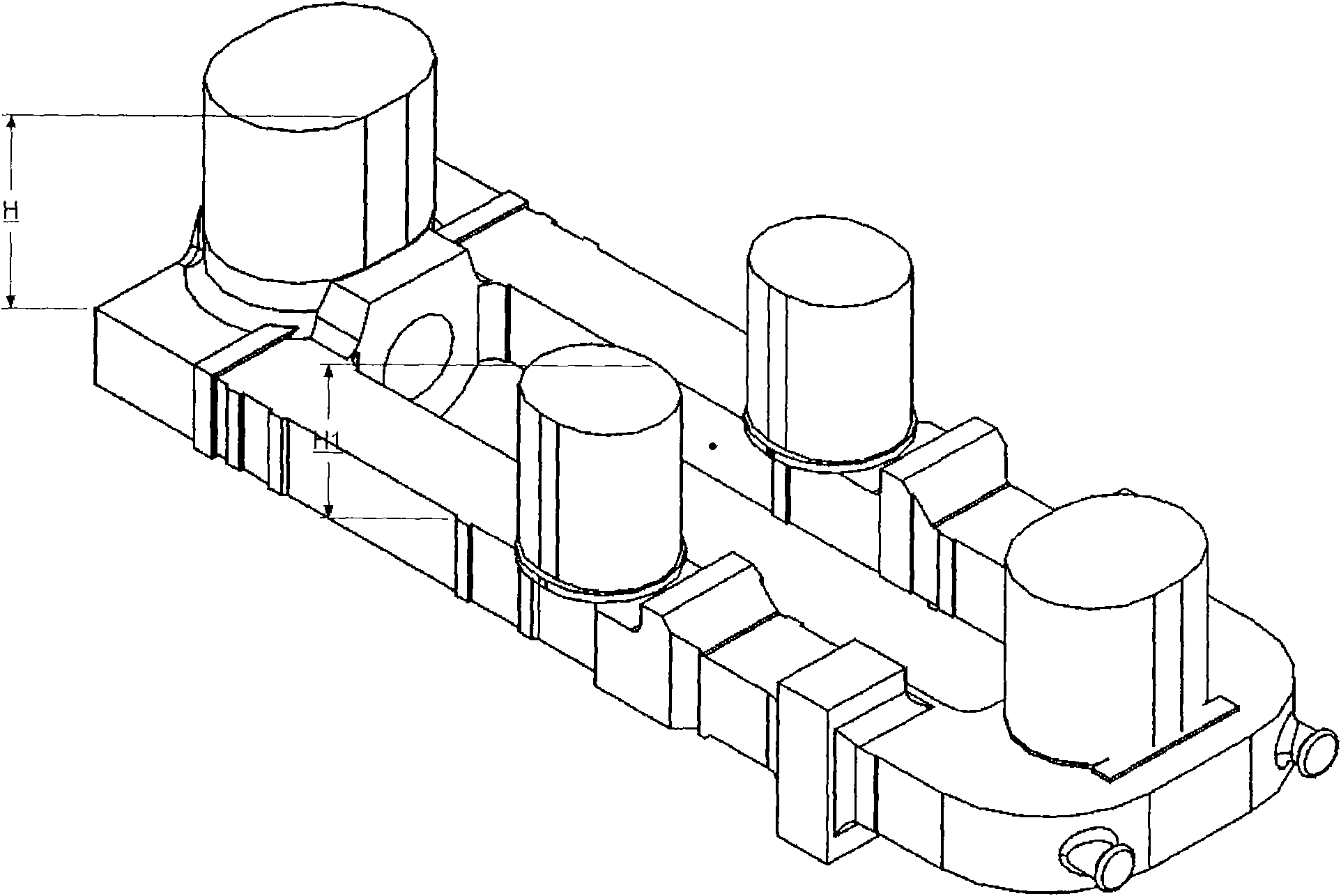

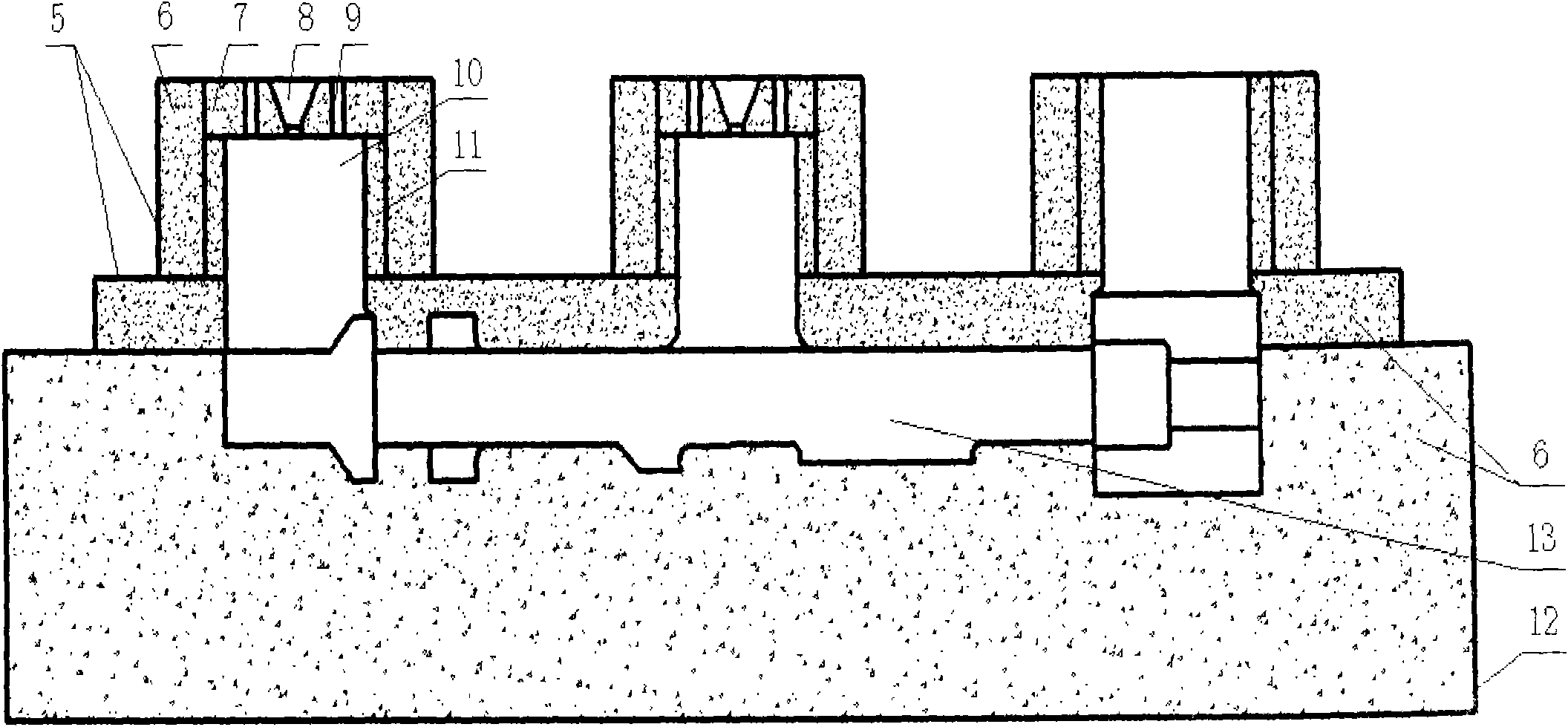

[0018] like figure 2 —— Figure 4 As shown, the present invention comprises: be located at the mold cavity 13 of the rough rolling mill horizontal roll stand blank formed by molding sand 6 in the casting pit 12 and be located at several risers 10 on the mold cavity 13, several risers 10 respectively Set in the sand box 5 formed by molding sand 6, a riser sleeve core 11 is arranged around the riser 10. This embodiment is: four risers 10 are provided, and the pouring heights H and H1 of the four risers 10 are set differently, and the riser 10 with a high pouring height H is arranged on the upper part 1 of the rough rolling mill horizontal roll stand blank, The other three risers with lower pouring height H1 are respectively arranged on the lower part 2 of the blank frame and the middle part of the column 3 of the blank frame. A cover core 7 is respectively assembled on each riser 10 whose pouring height H1 is lower than the pouring height H, and the cover core 7 is made of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com