Pouring, vibrating and entraining air automatic lifting device

An automatic lifting and lifting frame technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of uneven distribution of raw materials, no vibrating device, unable to lift and so on, achieve simple structure and prevent splashing everywhere. The effect of shooting and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

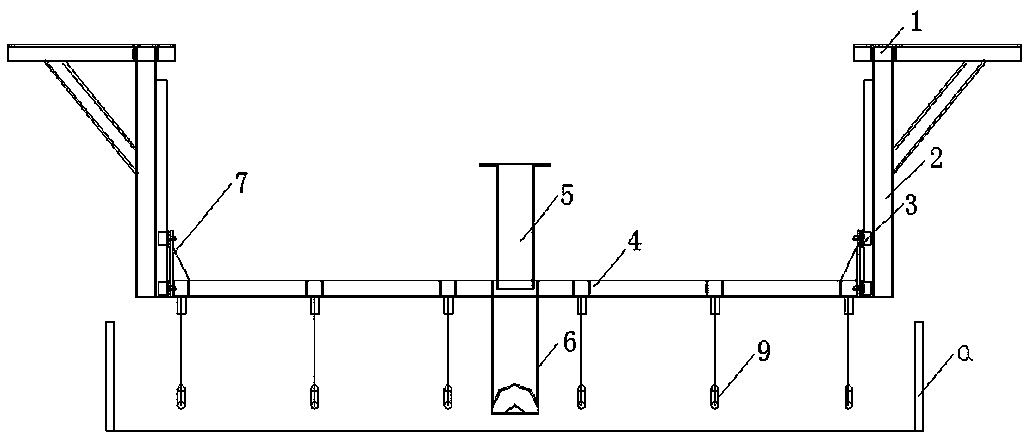

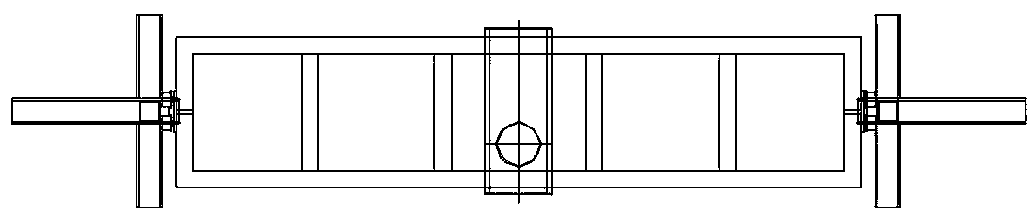

[0009] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it comprises a fixed frame 1, a guide rail 2, a guide wheel 3, a lifting frame 4, a pouring pipe 5, a fastening frame 6, a suspension spring 7 and a vibrating rod 9, and the top of the guide rail 2 is fixed A fixed frame 1 is provided, and a guide wheel 3 is provided on the lower inner side of the guide rail 2, and the two guide wheels 3 are connected by a suspension spring 7, and the lower part of the guide rail 2 is connected with the lifting frame 4, and the pouring pipe 5 is arranged in the middle of the lifting frame 4, A fastening frame 6 is arranged below the pouring tube 5 , and several vibrating rods 9 are evenly arranged below the lifting frame 4 .

[0010] The working principle of this embodiment is: the mold car a is placed under the vibrating rod 9, the slurry is transported to the pouring pipe 5 by the feed pipe, poured into the mold car from the pouring port, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com