Welding method for setting double pulse welding parameters based on mathematical model

A mathematical model and welding method technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems that affect the stability of the welding process and the shape of the weld seam, the complexity of the welding specification, and the deterioration of the welding effect

Active Publication Date: 2011-06-15

EAST GRP CO LTD

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the dual-pulse MIG welding method of welding power sources at home and abroad, the welding specifications are more complicated, and there are many important parameters, such as the base value of the strong and weak pulse group, the magnitude and time of the peak current, the frequency and duty cycle of the strong and weak pulse group, As well as wire feeding speed and welding speed, etc., all directly affect the stability of the welding process and the shape of the weld

Due to the relatively high matching requirements of aluminum for welding parameters, any unreasonable selection of any parameter may lead to a sharp deterioration of the welding effect

How to reasonably match various parameters and form an expert database for unified adjustment undoubtedly brings huge challenges to welding developers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

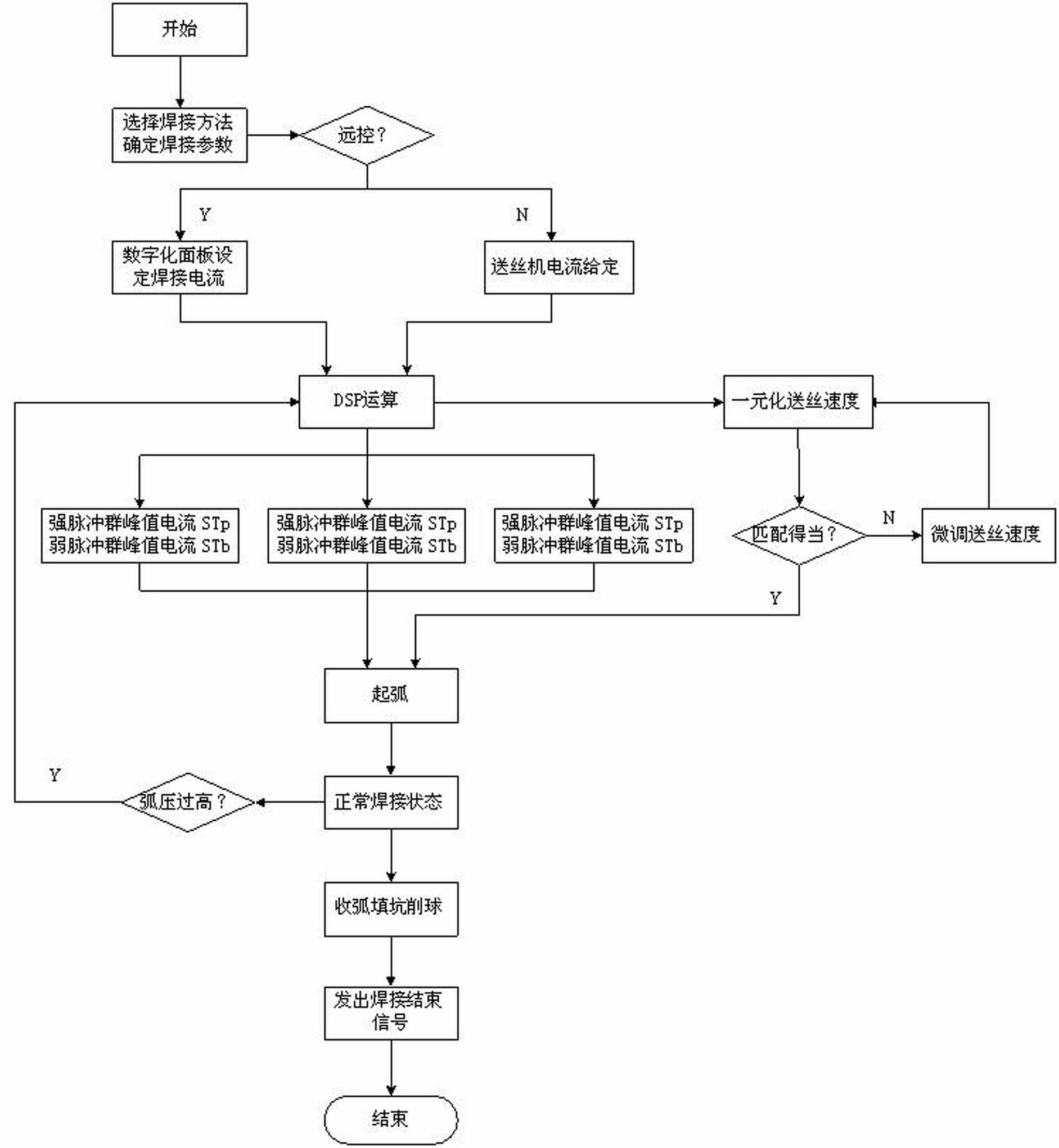

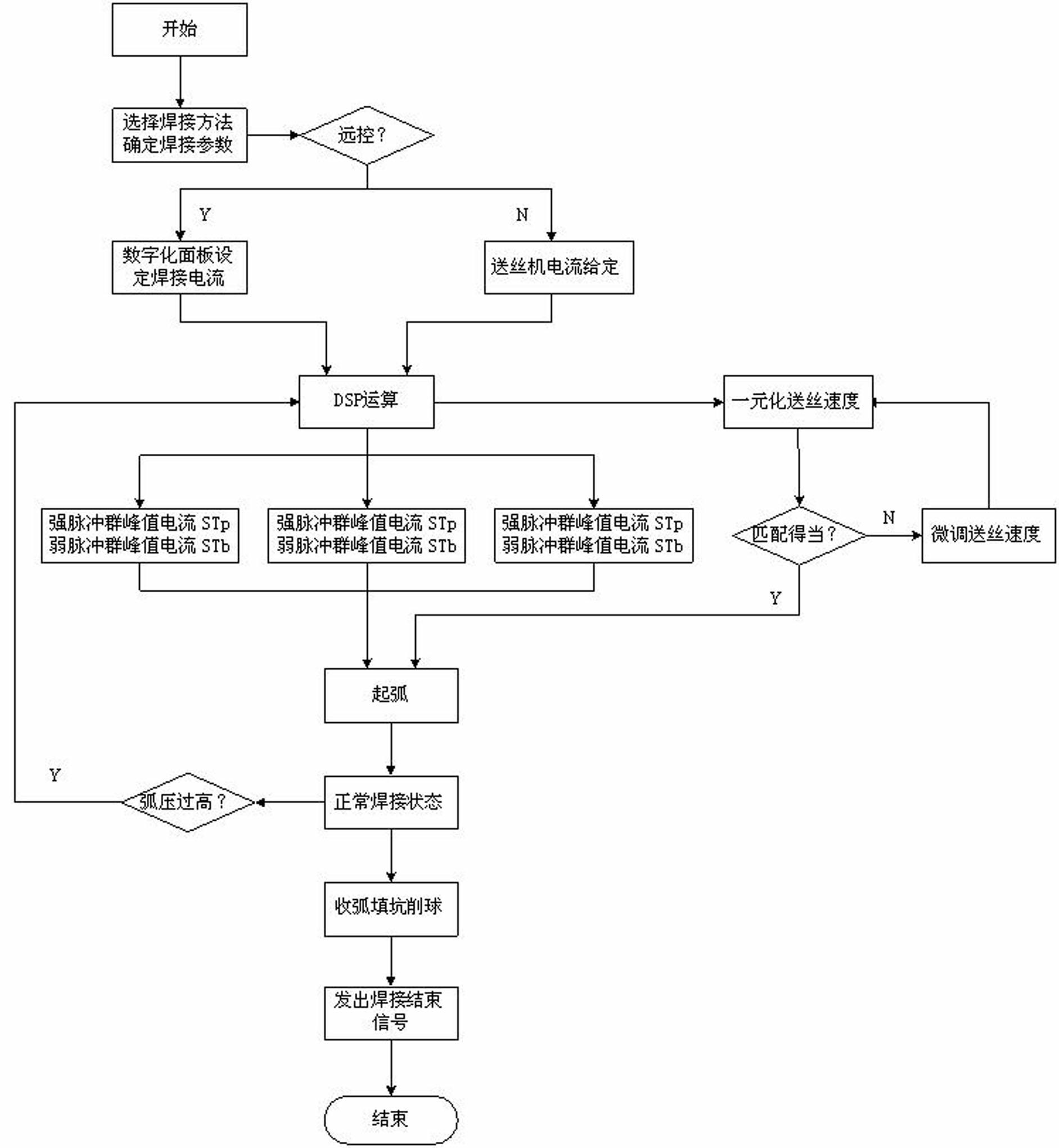

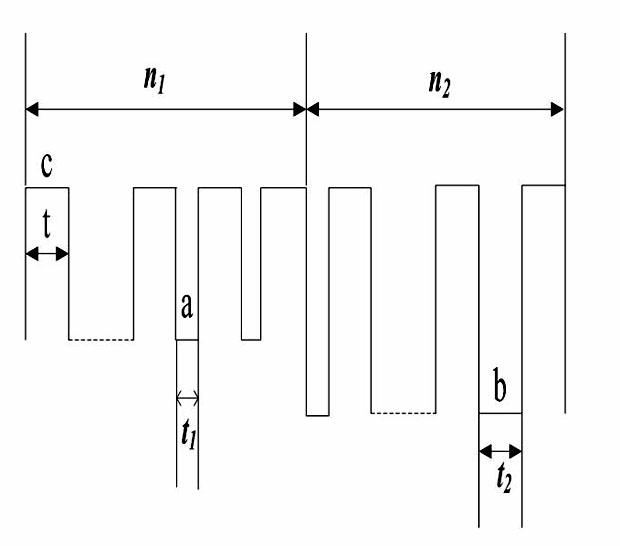

The invention relates to the technical field of digital welding of aluminum magnesium alloy, in particular to a welding method for setting double pulse welding parameters based on a mathematical model, and discloses a method for realizing welding by a fixed frequency and variable frequency calculation method of a double pulse metal-inert gas (MIG) welding wave form which is designed based on the mathematical model. Continuous adjustable change is performed according to a certain rule based on basic values a and b of strong and weak pulse groups, numbers n1 and n2 of strong and weak pulses are subjected to assistant adjustment, and a welding current range can be effectively expanded, so that the welding current in a wider range can be adjusted continuously. Meanwhile, at the transition stage of the strong and weak pulses, a gradual change mode is adopted by the pulse basic values to ensure that the transition of the strong and weak pulses is smoother, and the welding process is more stable.

Description

A Welding Method Based on Mathematical Model to Set Double Pulse Welding Parameters technical field The invention relates to the technical field of digital welding of aluminum-magnesium alloys, in particular to a welding method for setting double-pulse welding parameters based on a mathematical model. Background technique FRONIUS company in Austria has done the best in the field of aluminum alloy welding expert database. The company has developed a series of digital inverter pulse MIG / MAG welding machines with expert database. The sales price of such high-end machines as FRONIUS can easily exceed hundreds of thousands or even hundreds of thousands of RMB, and its core is the constantly upgraded expert database applicable to various welding consumables. The domestic research and development of aluminum alloy double pulse database is still in the experimental research stage, in Beijing in 2010. No domestically produced double-pulse MIG welding machine that can continuously ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/095B23K9/09

Inventor 薛家祥陈小峰林放徐海波崔龙彬

Owner EAST GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com