Laser offset welding method suitable for magnesium/steel and magnesium/titanium

A welding method and laser technology, which is applied in the field of fusion welding of magnesium/steel, magnesium/titanium, and welding between dissimilar metals. The requirements of adaptability and the effect of solving the problem of energy inhomogeneity

Inactive Publication Date: 2011-06-15

HARBIN INST OF TECH

View PDF4 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a laser offset welding method suitable for magnesium / steel and magnesium / titanium in view of the problems that air holes are likely to be generated during welding of low-melting point materials and poor mechanical properties of joints when welding dissimilar materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

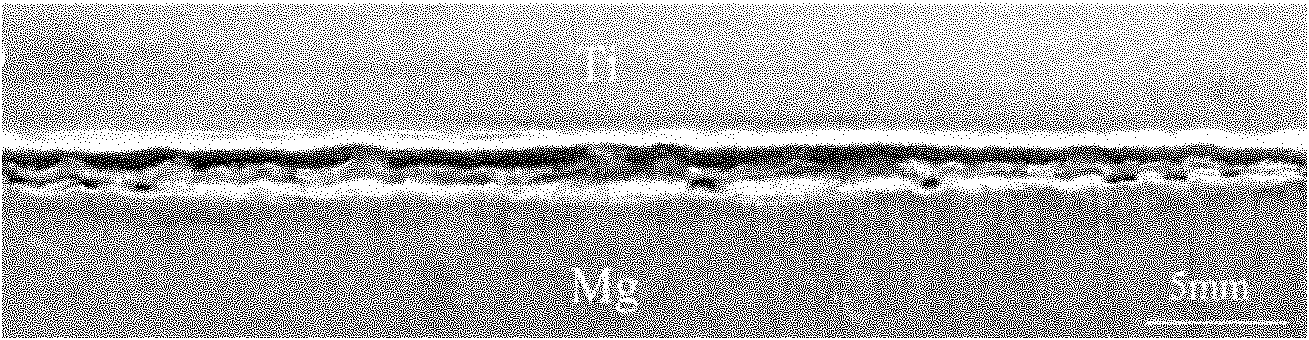

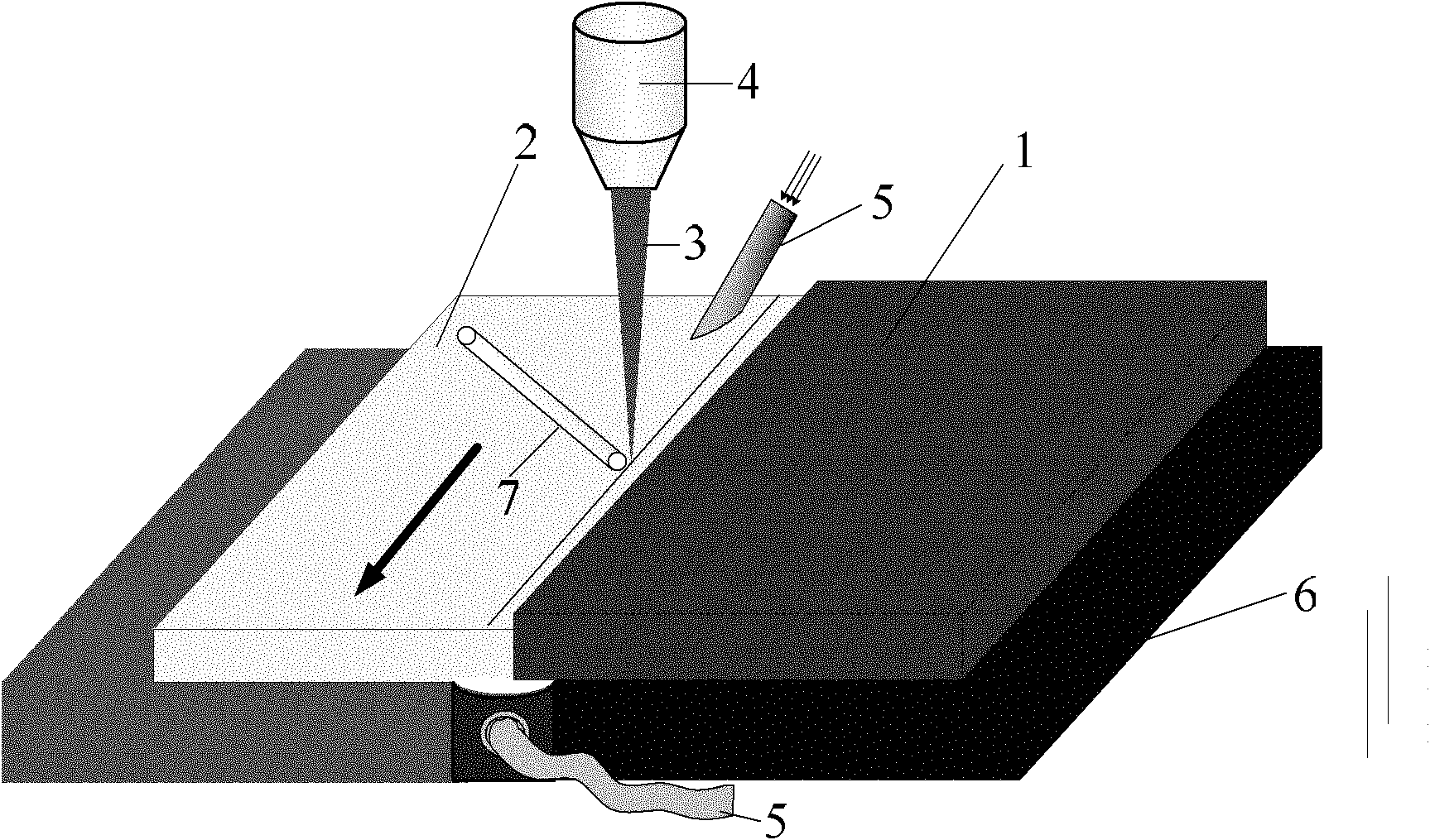

The invention relates to a welding method for dissimilar metals, and in particular relates to a laser offset welding method suitable for magnesium / steel and magnesium / titanium. The method comprises the following steps: (1) fixing to-be-welded magnesium and steel or magnesium and titanium on a work table, and jointing by use of zero-gap seamless joints; and (2) achieving the welding by irradiating steel or titanium with laser under the conditions of filling welding wire or not, wherein the protection gas flow rate is1 L / min to 50 L / min, the welding speed is 0.1 m / min to 1 m / min, the laser power is 1 W to 10 kW, and the laser offset 0.1 mm to 0.8 mm. The high-melting-point side material can be molten by irradiating with the laser beam, and the low-melting-point side material can be molten through heat conduction so as to achieve the connection between the two kinds of materials. When a laser beam directly irradiates a high-reflectivity material, such as a magnesium alloy, the material has low energy absorption rate. However, the laser offset welding method can solve the problem, and can reduce the defects, such as welding seams and pores, generated on the material with a low melting point or a low bolting point.

Description

Laser offset welding method for magnesium / steel, magnesium / titanium technical field The invention relates to a welding method between dissimilar metals, in particular to a fusion welding method of magnesium / steel and magnesium / titanium, and belongs to the field of welding. Background technique With the increasingly severe environmental problems, it is imperative to save energy, reduce emissions and promote "low-carbon" life. Therefore, light metals such as magnesium alloys and aluminum alloys are widely used in aviation, electronics, transportation and other fields to successfully replace traditional structural materials and reduce the weight of the structure itself, which has become the focus of research. In the automobile industry, composite structural parts are mainly dissimilar joints formed by light metals such as magnesium and aluminum and steel and titanium. In particular, there are many spliced plates and unequal thick plates of this dissimilar material. Due to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K103/08B23K26/24B23K26/26

Inventor 李俐群檀财旺李福泉雷正龙

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com