Warm air adjusting system for small motor vehicle

A technology for regulating systems and motor vehicles, applied to vehicle parts, heating/cooling equipment, air handling equipment, etc., can solve problems such as waste of heat energy, cold wind, slow heating, etc., and achieve the effect of ensuring the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

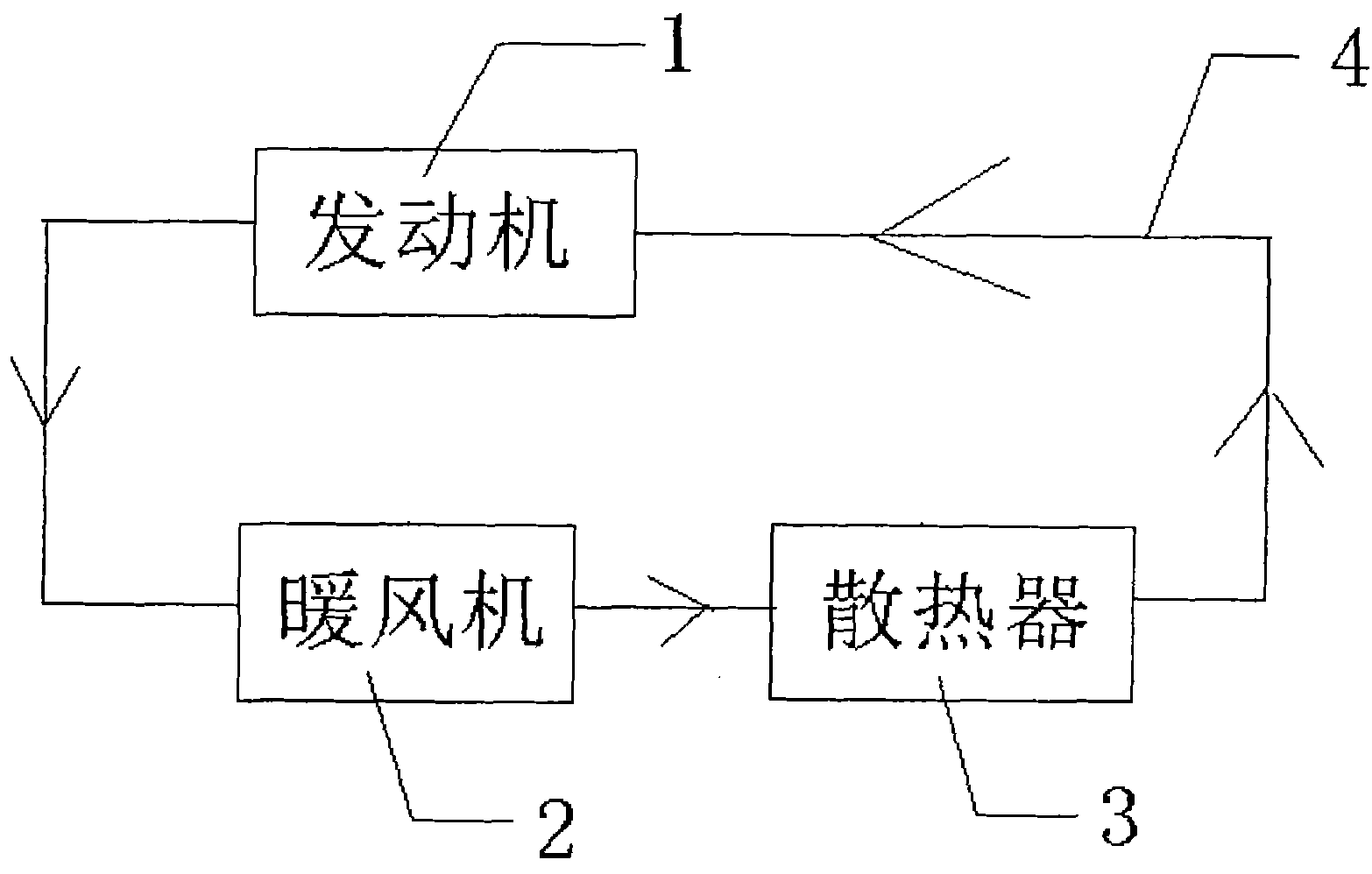

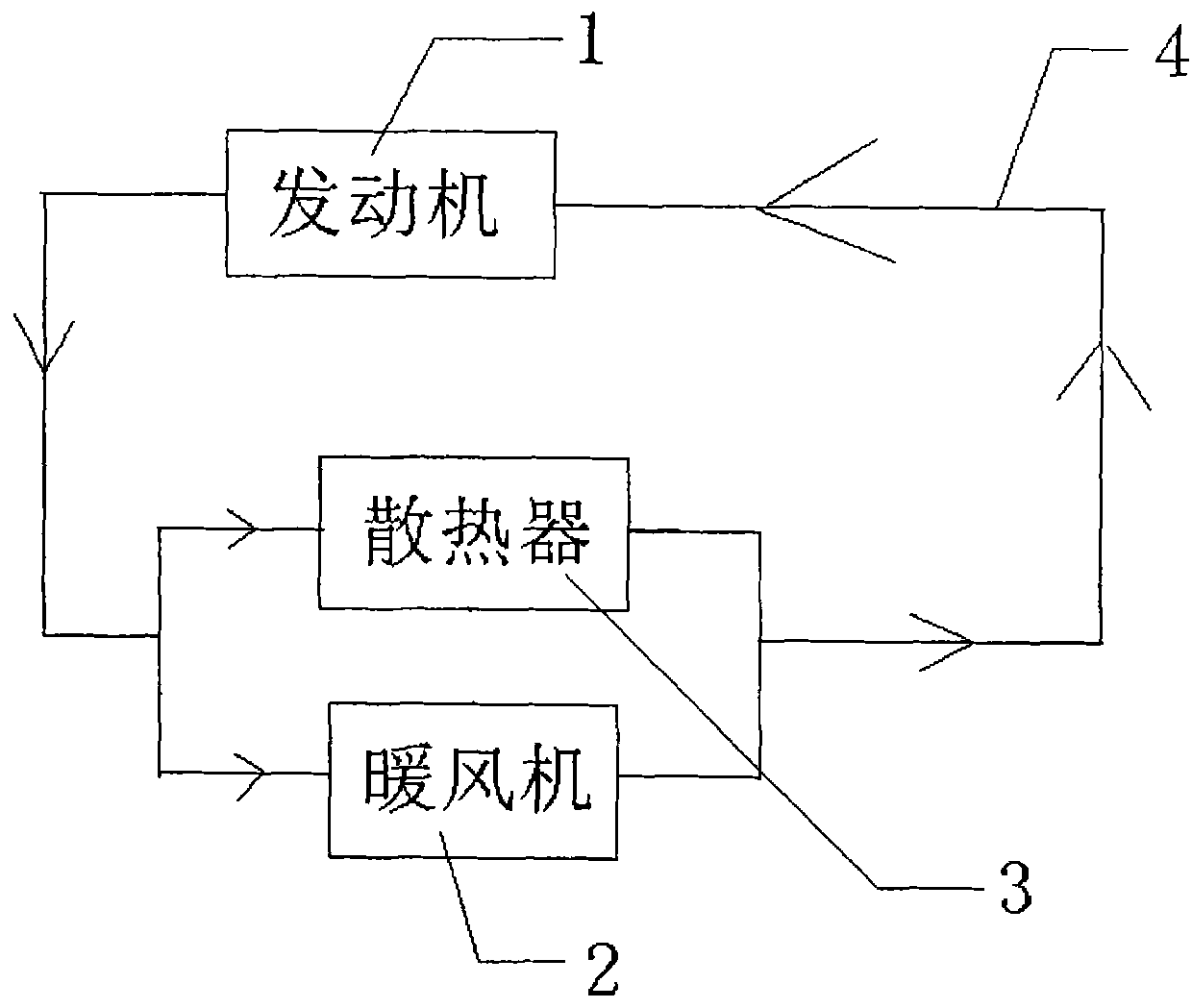

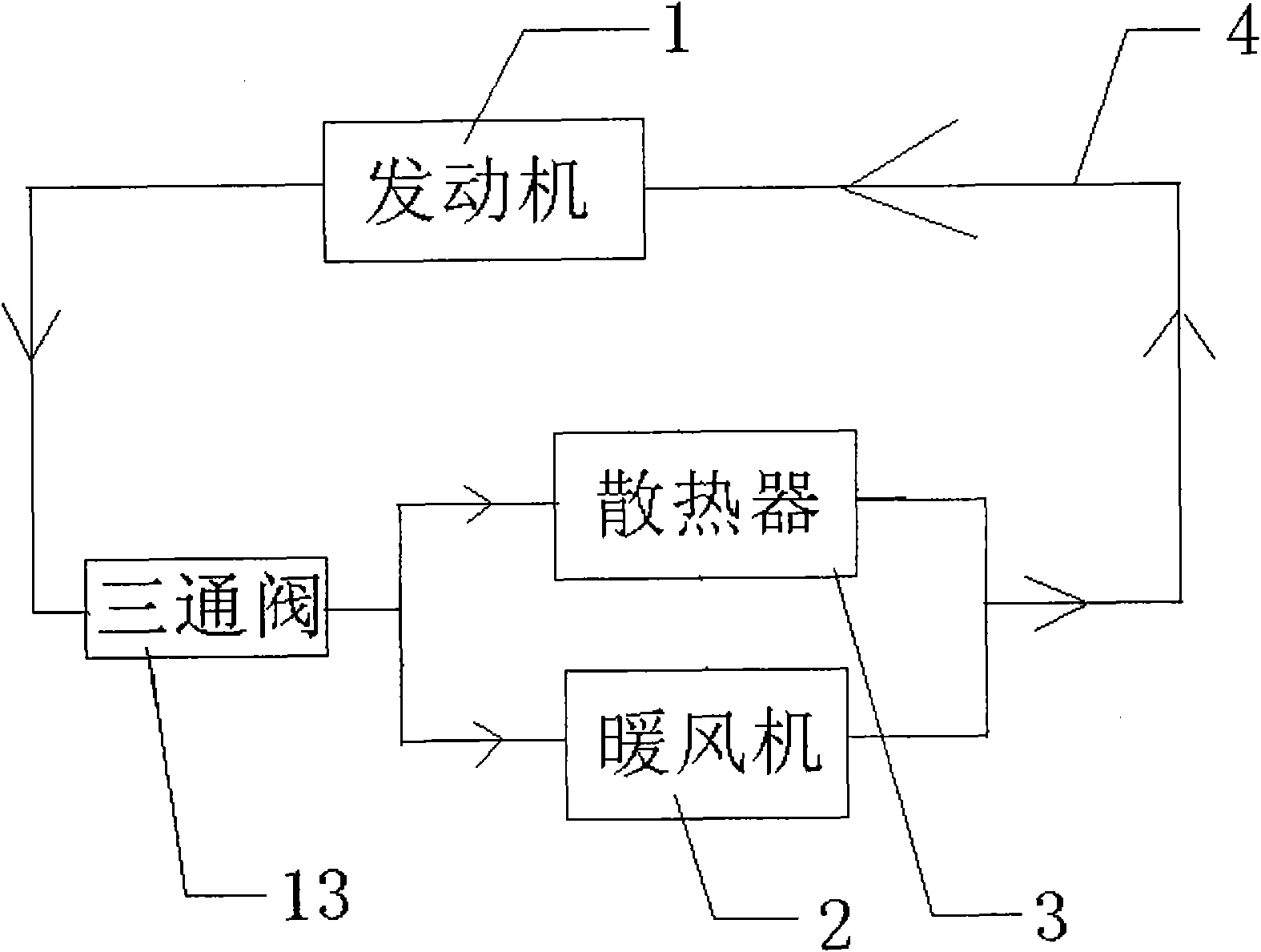

Embodiment 1

[0015] Such as image 3 and Figure 4 As shown, a warm air regulating system for a small motor vehicle includes an engine 1, a heater 2, and a radiator 3, and the engine 1, the heater 2, and the radiator 3 are connected through a conduit 4, and is characterized in that: the engine A three-way valve 13 is also connected between 1 and the heater 2 and radiator 3, and the three-way valve 13 is respectively connected to the engine 1, the heater 2 and the radiator 3 through the conduit 4, and the engine 1 is connected to the engine 1 through the three-way valve 13. Connect with heater 2 and radiator 3.

[0016] Such as Figure 5 As shown, the three-way valve 13 has four ports, which are engine port 7, heater port 6, radiator port 5 and electronic adjustment handle port 8, and there is a ball valve at the intersection of the four ports. 10. There are two guide holes 11 on the ball valve 10, and there is a groove 14 on the outer circumference of the ball valve. The electronic adju...

Embodiment 2

[0022] It is the same as the warm air regulating system for a small motor vehicle in Embodiment 1, the difference is that: the 6 ends of the heater port and the 5 ends of the radiator port are integrated, the engine port adopts a split design, and is connected with the The heater port 6 ends and the radiator port 5 are connected by rubber hoses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com