Mechanical wear testing device

A technology of mechanical wear and test device, applied in the field of machinery, can solve the problems of affecting the accuracy of wear test, taking a long time for the test, and unable to ensure the ratio of sand and liquid, so as to improve the horizontal alignment effect, improve the test effect, and improve the detection effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

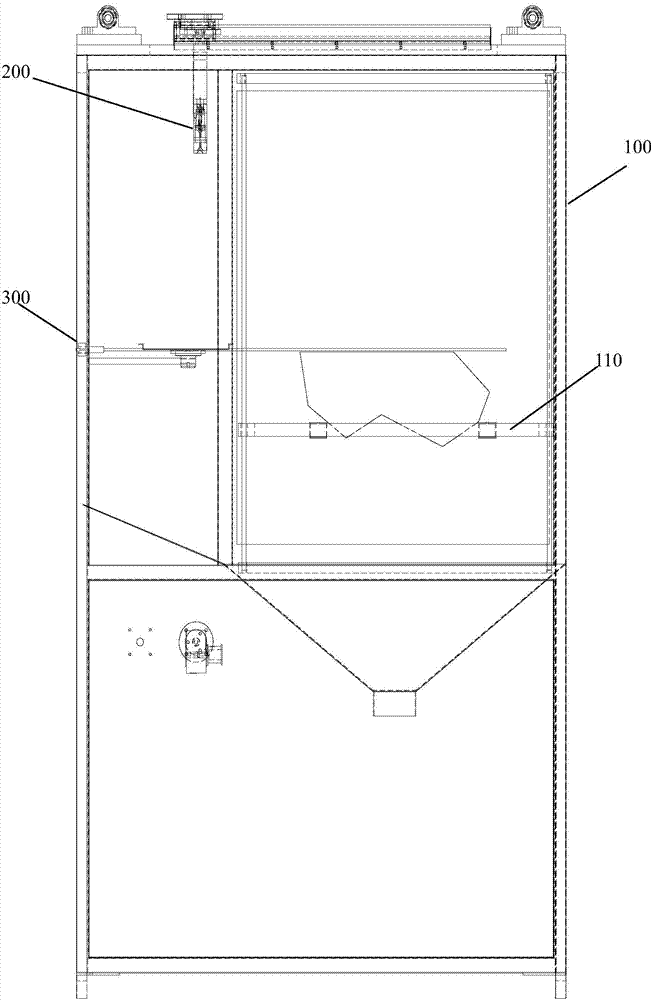

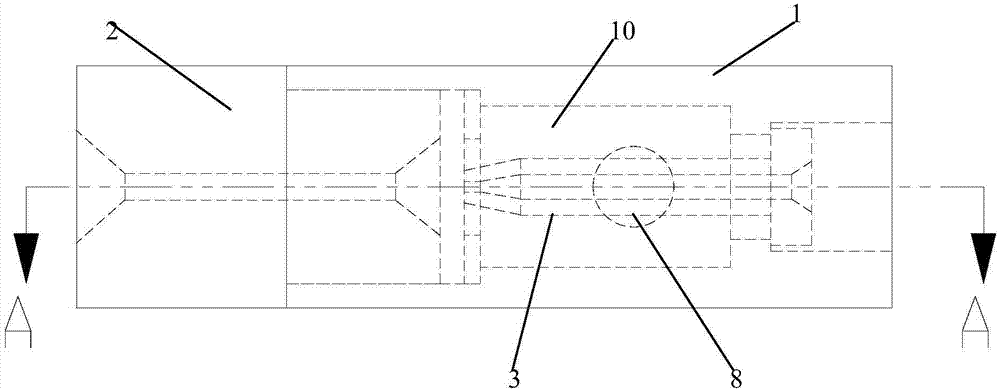

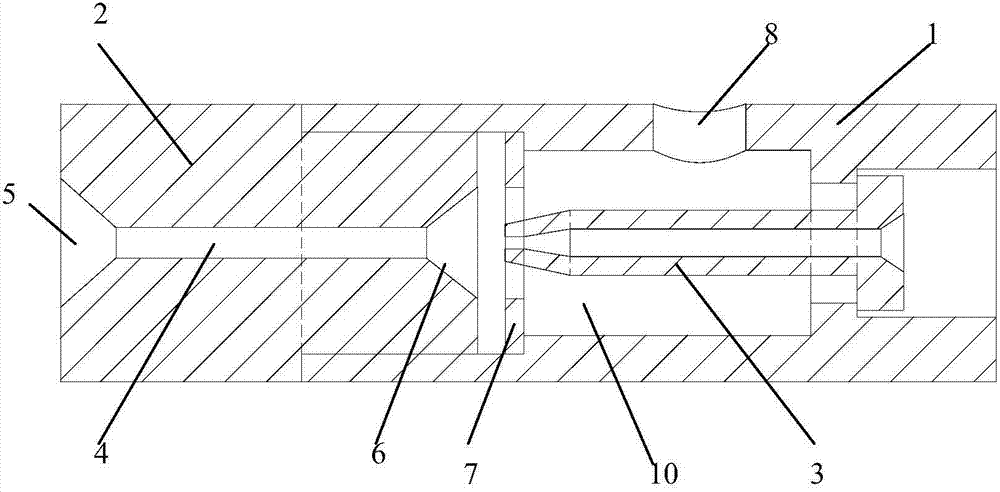

[0026] Such as figure 1 As shown, the mechanical wear test device of the present invention includes a cabinet 100, which can be driven to move up and down and is arranged in the cabinet to carry a bracket 110 for carrying samples, which is vertically arranged on the upper part of the inner space of the cabinet and can be driven left and right The spray gun 200 used for the mechanical wear test of the reciprocating plastic light distribution mirror is horizontally arranged on one side of the cabinet to assist the laser pointer 300 of the flush setting of the sample, and is arranged on the outside of the cabinet to provide sand to the spray gun. A water-mixed sand-water mixing agitator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com