Circulating cooling device for wind power generation

A technology of circulating cooling and wind wheel, applied in wind power generation, wind turbines, engines, etc., can solve the problems of motor heating, engine room temperature rise, damage, etc., to extend the service life, reduce the impact of direct blowing, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

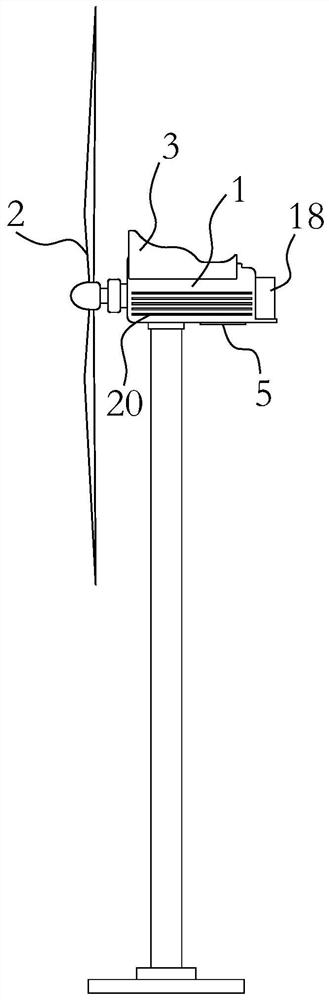

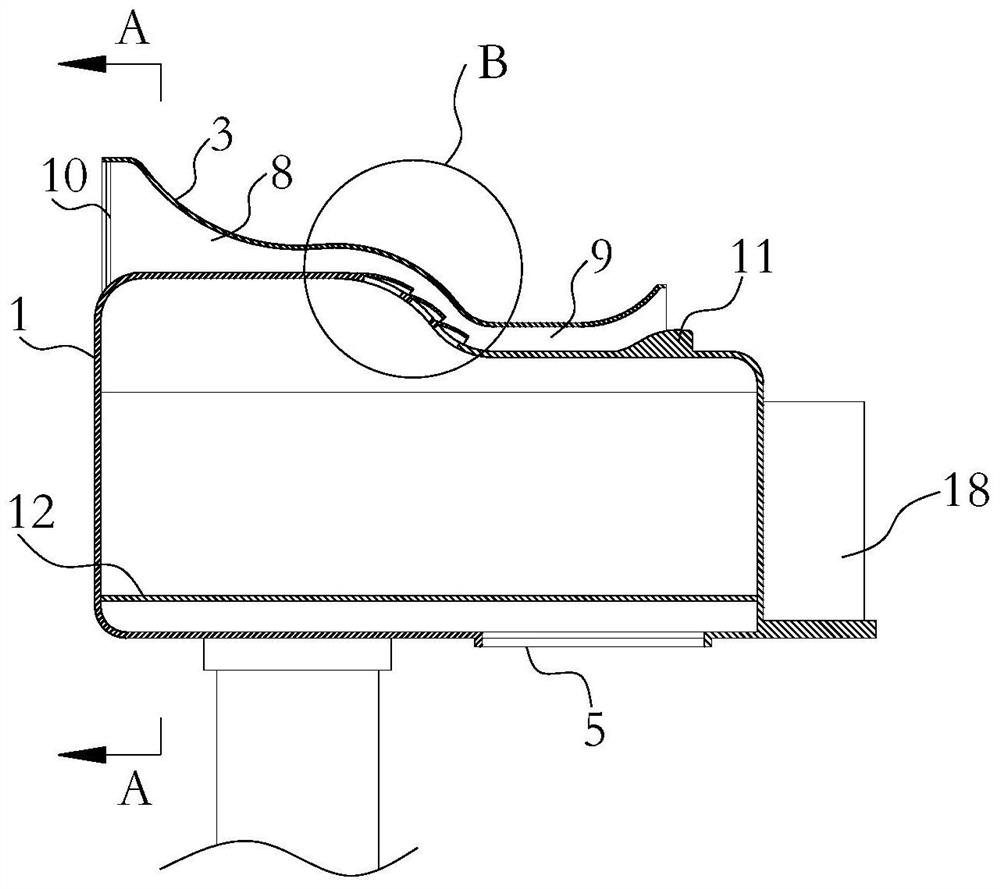

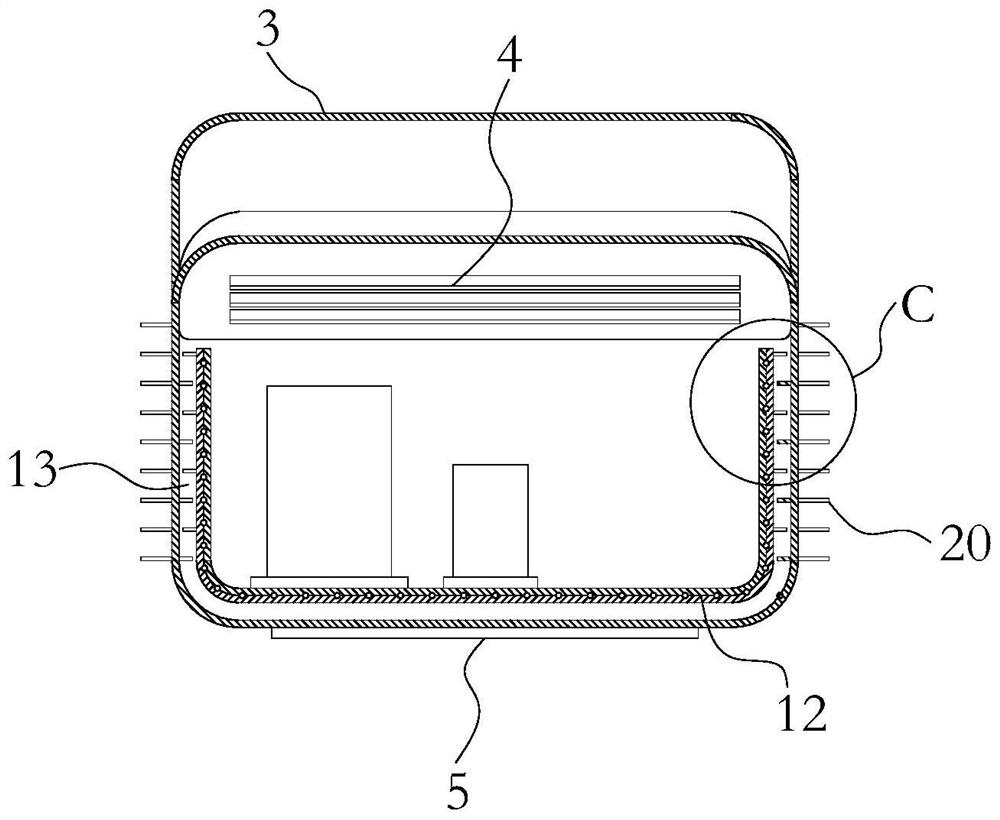

[0023] like Figure 1-6 As shown, a circulating cooling device for wind power generation is mainly used to cool down the overall temperature of the cabin 1 of the wind power generation equipment, so as to ensure that the functional equipment inside the cabin 1 has a stable working condition and prolong its service life. The present invention includes a machine room 1 installed on an iron tower, the front end of the machine room 1 is provided with a wind wheel 2, and the front end is also the windward end of the machine room 1, that is, figure 2 in the left end. The upper part of the cabin 1 is fixedly provided with an air collection cover 3, which is used to converge the high-altitude high-speed airflow on the top surface of the cabin 1 to increase the wind speed. An ejection channel is formed between the air collection cover 3 and the top surface of the machine compartment 1, and the high air flow flows in the ejection channel. The top of the machine compartment 1 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com