Assembly tooling for diesel engine valve collet

A diesel engine and valve lock clip technology, which is applied to assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as low assembly efficiency, affecting the smooth operation of valves, and poor coaxiality, and achieve the effect of improving assembly work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

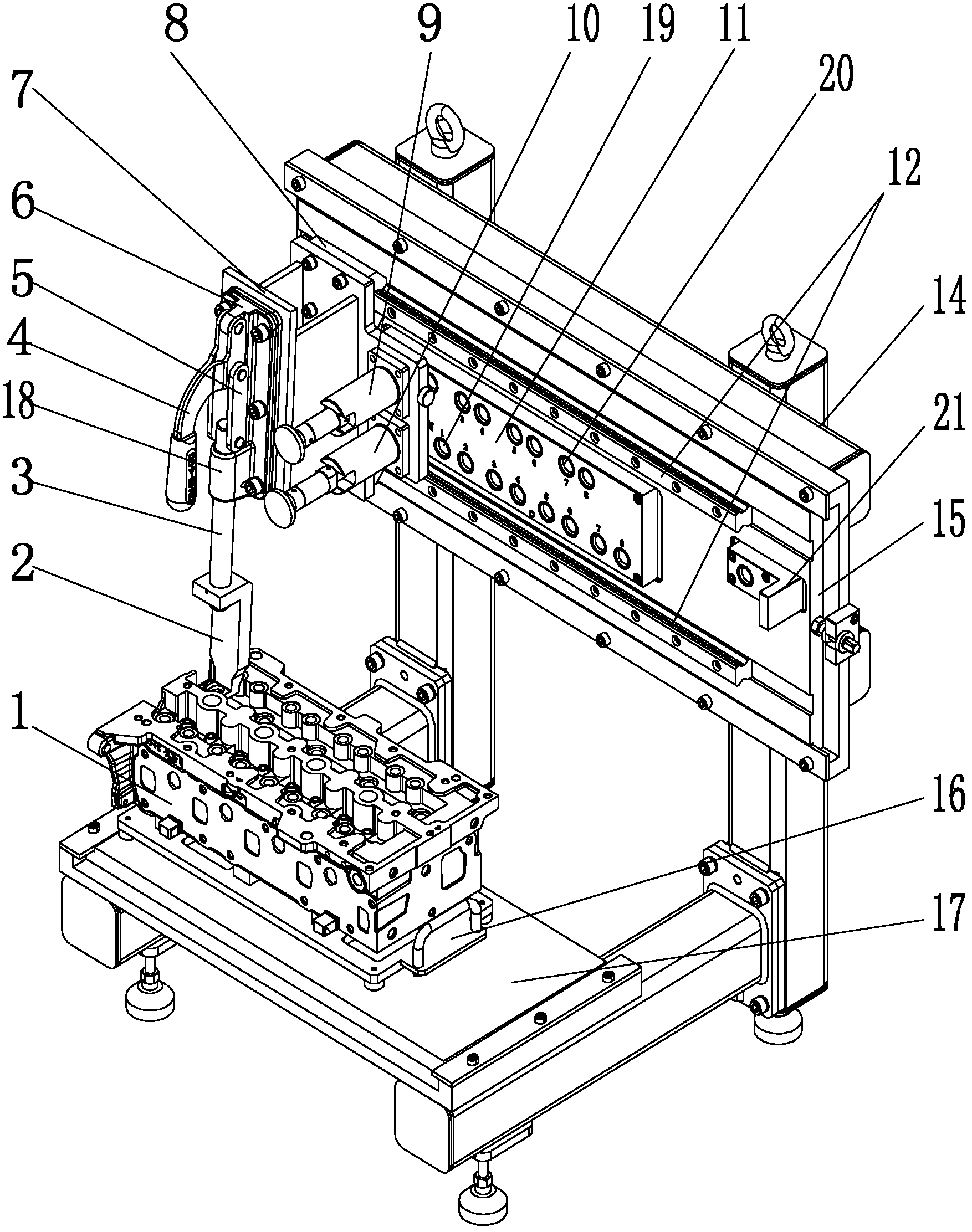

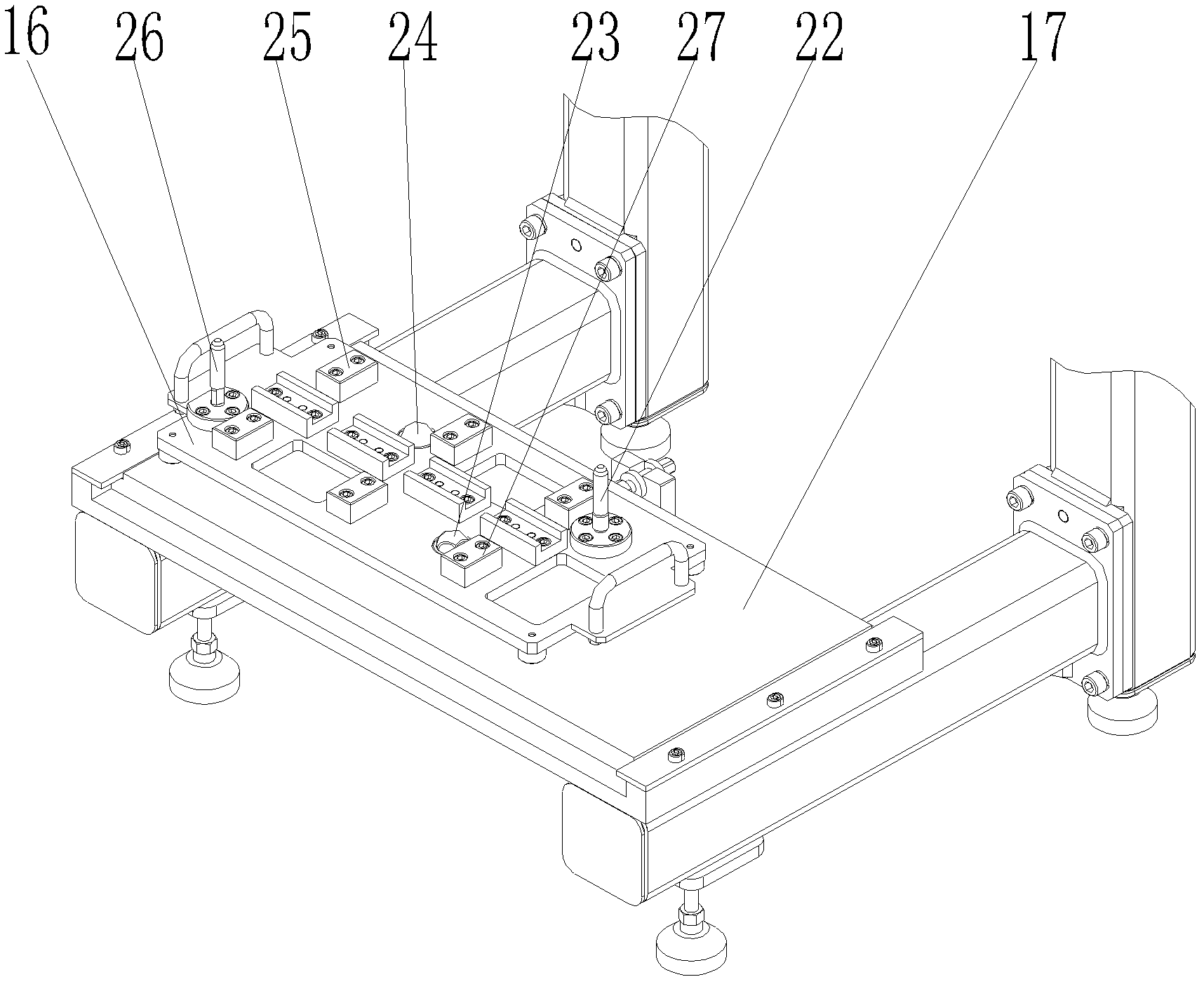

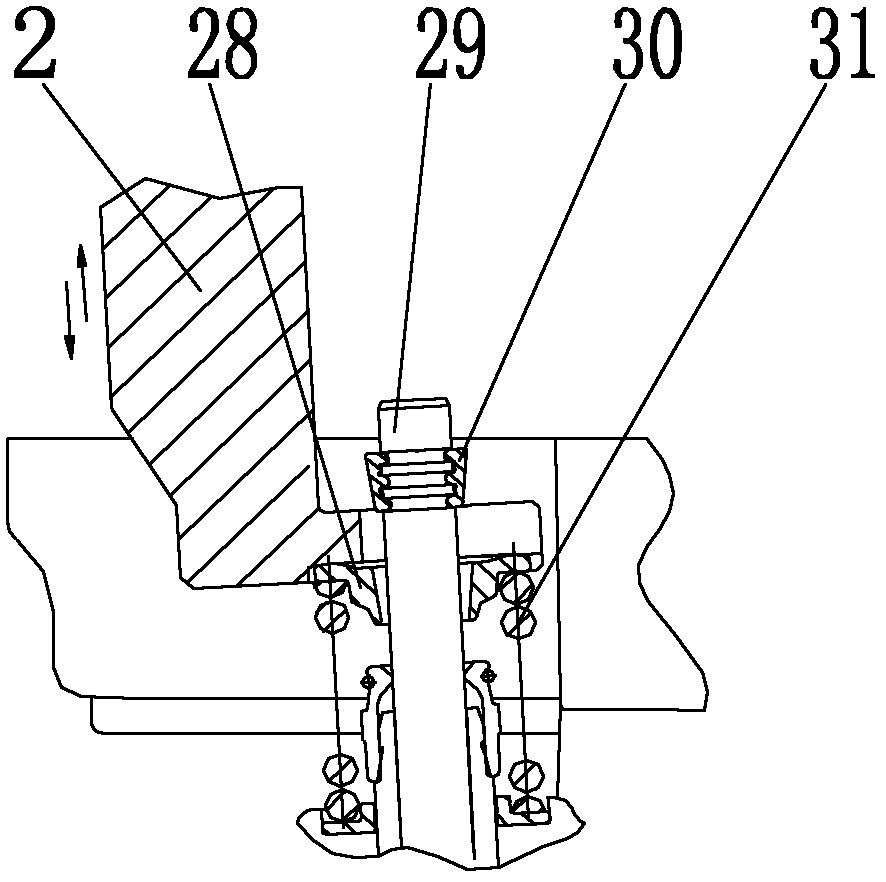

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the base of the present invention, image 3 It is a structural schematic diagram of the installation process of the present invention, Figure 4 It is a horizontal guide rail and a slide block with a cross-sectional structure, as shown in the figure: the diesel engine valve lock clip assembly tool of the present embodiment includes a fork-shaped pressure head 2, and the opening of the fork-shaped pressure head 2 is smaller than that of the valve spring upper seat 28. The transverse dimension is used to press down the upper seat 28 of the valve spring. The opening of the fork head 2 is at least larger than the outer diameter of the rod section of the valve ejector rod 29 for installing the valve lock clip 30. The fork head 2 is used to press down the upper seat 28 of the valve spring. And exposed valve push rod 29 is used to install the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com