Facility and method for ferronickel production through coal-based powder state reduction of red soil nickel ores

A laterite nickel ore and coal-based technology, which is applied in the field of nickel ferronickel production from laterite nickel ore, can solve the problems of unsmooth working conditions, high cost and high energy consumption, and can reduce the cost of raw materials, improve the utilization rate, and achieve high thermal energy utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

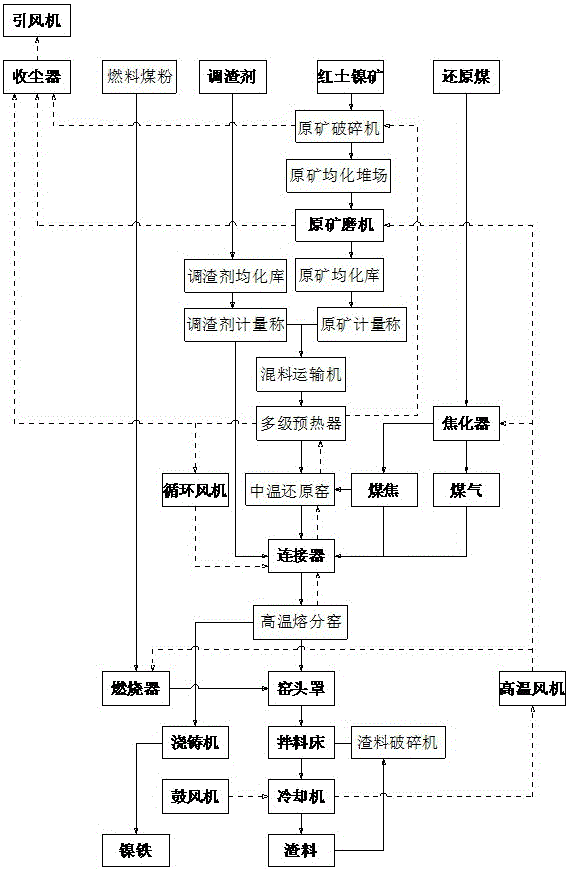

[0032] A facility for producing ferronickel by coal-based powder reduction of laterite nickel ore includes: raw ore crusher, homogenizing storage yard, pulverizer, ore powder homogenizing storehouse, ore powder measuring scale, slag adjusting powder homogenizing store, slag adjusting Powder weighing scale, mixing conveyor, burner, coker, coal coke weighing scale, gas pipeline, multi-stage preheater, medium temperature reduction kiln, connector, high temperature melting kiln, casting machine, mixing bed, slag crushing machine, cooler, dust collector, blower, high temperature fan and circulation fan;

[0033]The raw ore crusher, homogenization yard, grinding machine, ore powder homogenization storage and mineral powder weighing scale are connected in sequence and then connected to the input end of the mixing conveyor, and the slag adjustment powder homogenization storage is connected to the slag adjustment powder weighing scale. The input end of the mixing conveyor; the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com