Preparation method of organic polymer modified ferric iron tetroxide multistage spheres

An organic polymer and ferric oxide technology, which is applied in the direction of ferrous oxide, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problem that the size of magnetic balls is difficult to control, affects the application of magnetic balls, and the synthesis process is complicated and other problems, to achieve the effect of improving solubility, satisfying production and application, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The first step, in a 50 ml flask, add 1 part of ferric acetate and 10 parts of polyvinylpyrrolidone into 20 ml of diethylene glycol, heat to 60°C and keep it for 30 minutes, stir well to prepare a reaction solution.

[0022] The second step, the reaction solution prepared in the first step is transferred to a high-pressure reactor with a 25 ml polytetrafluoroethylene liner. After reacting at 140°C for 24 hours, the reactor is naturally cooled to about 60°C, and 5 ml methanol, the product was filtered, washed several times with absolute ethanol, and the sample was vacuum-dried to obtain organic polymer-modified ferric oxide multi-stage balls with regular size and shape.

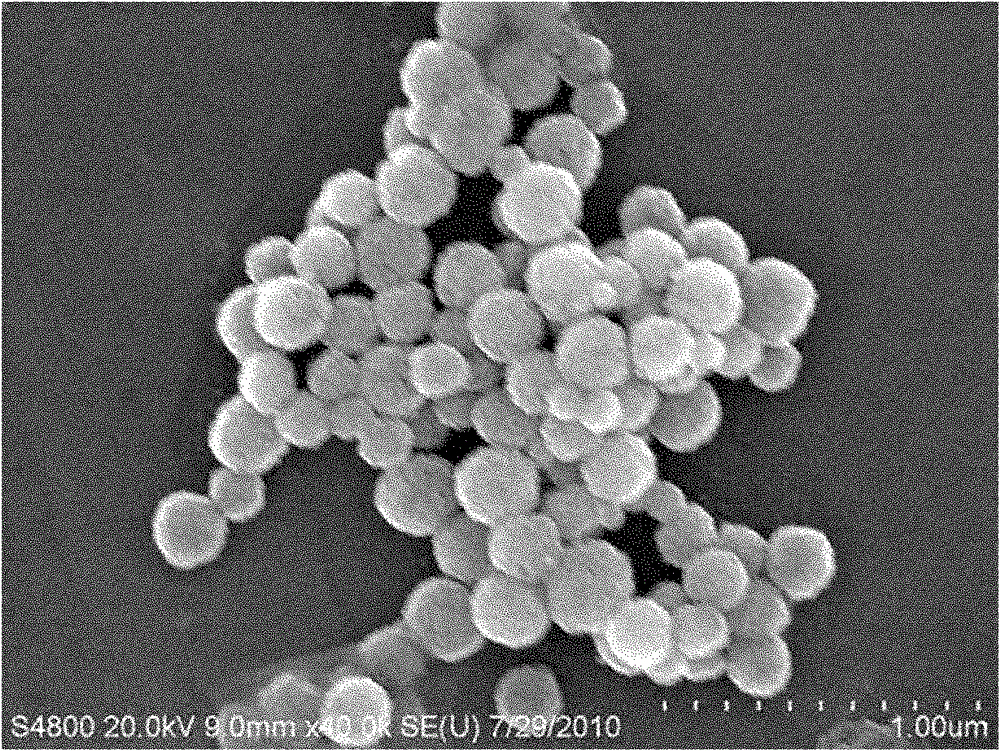

[0023] figure 1 It is a scanning electron micrograph of the organic polymer modified ferric iron tetroxide multilevel sphere prepared in Example 1. It can be seen from the figure that the ferroferric oxide has a spherical structure with a size of about 250nm. Careful observation shows that the spheric...

Embodiment 2

[0025] The first step, in a 50 ml flask, add 10 parts of ferric acetate and 20 parts of polyacrylic acid into 20 ml of ethylene glycol, heat to 80°C and keep for 30 minutes, fully stir to prepare a reaction solution.

[0026] In the second step, transfer the reaction solution prepared in the first step into a high-pressure reactor with a 25 ml polytetrafluoroethylene liner. After reacting at 200°C for 48 hours, the reactor is naturally cooled to about 60°C, and 5 ml methanol, the product was filtered, washed several times with absolute ethanol, and the sample was vacuum-dried to obtain organic polymer-modified ferric oxide multi-stage balls with regular size and shape.

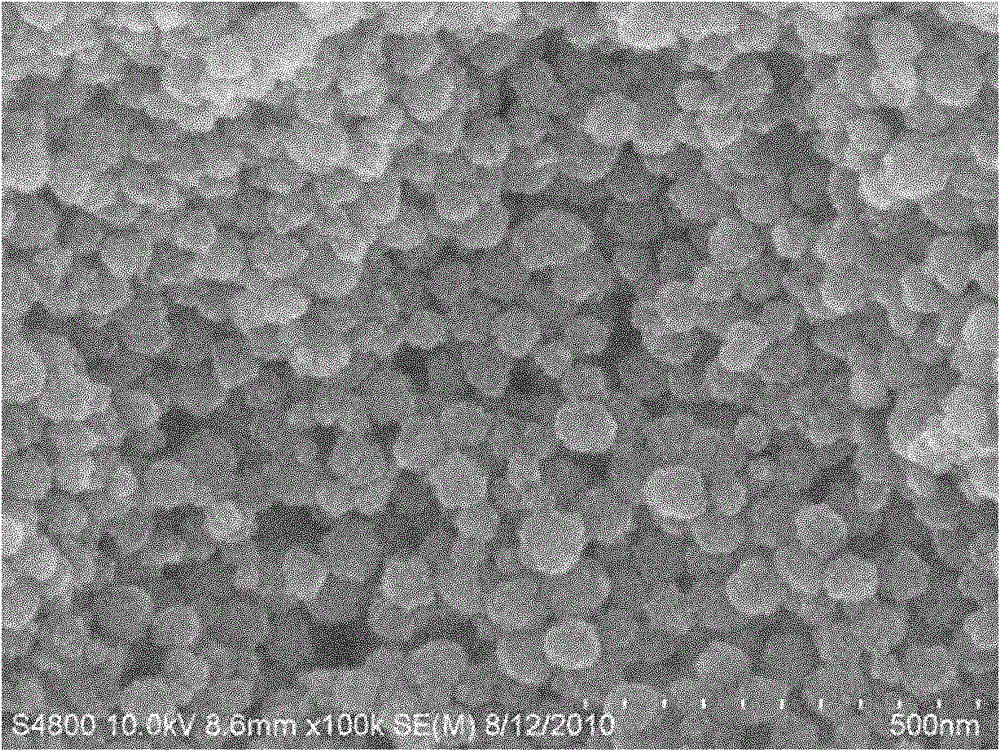

[0027] figure 2 It is a scanning electron micrograph of the organic polymer modified ferric iron tetroxide multilevel sphere prepared in Example 2. It can be seen from the figure that the ferroferric oxide has a spherical structure with a size of about 150nm. Careful observation shows that the spherical str...

Embodiment 3

[0029] The first step, in a 50 ml flask, add 1 part of ferric chloride hexahydrate and 20 parts of polyethylene glycol carboxylated at both ends to 1 ml of glycerol, heat to 60 ° C and keep for 30 minutes, Fully stir to prepare the reaction liquid.

[0030] The second step, the reaction solution prepared in the first step is transferred to a high-pressure reactor with a 25 ml polytetrafluoroethylene liner. After reacting at 180°C for 72 hours, the reactor is naturally cooled to about 60°C, and 5 ml methanol, the product was filtered, washed several times with absolute ethanol, and the sample was vacuum-dried to obtain organic polymer-modified ferric oxide multi-stage balls with regular size and shape.

[0031] image 3 It is a scanning electron micrograph of the organic polymer modified ferric iron tetroxide multilevel sphere prepared in Example 3. It can be seen from the figure that the ferroferric oxide has a spherical structure with a size of about 150nm. Careful observa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com