Antiseptic wear-resisting freezing adhesion-resisting one coat paint and preparation method thereof

An anti-corrosion, wear-resistant, anti-freezing and sticking technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult anti-corrosion, wear-resistant, anti-icing, etc., and achieve good anti-corrosion effect.

Inactive Publication Date: 2011-06-15

ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

View PDF3 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing coating protection technology for wind turbine blades in China is difficult to meet the requirements of anti-corrosion, wear resistance and anti-icing at the same time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

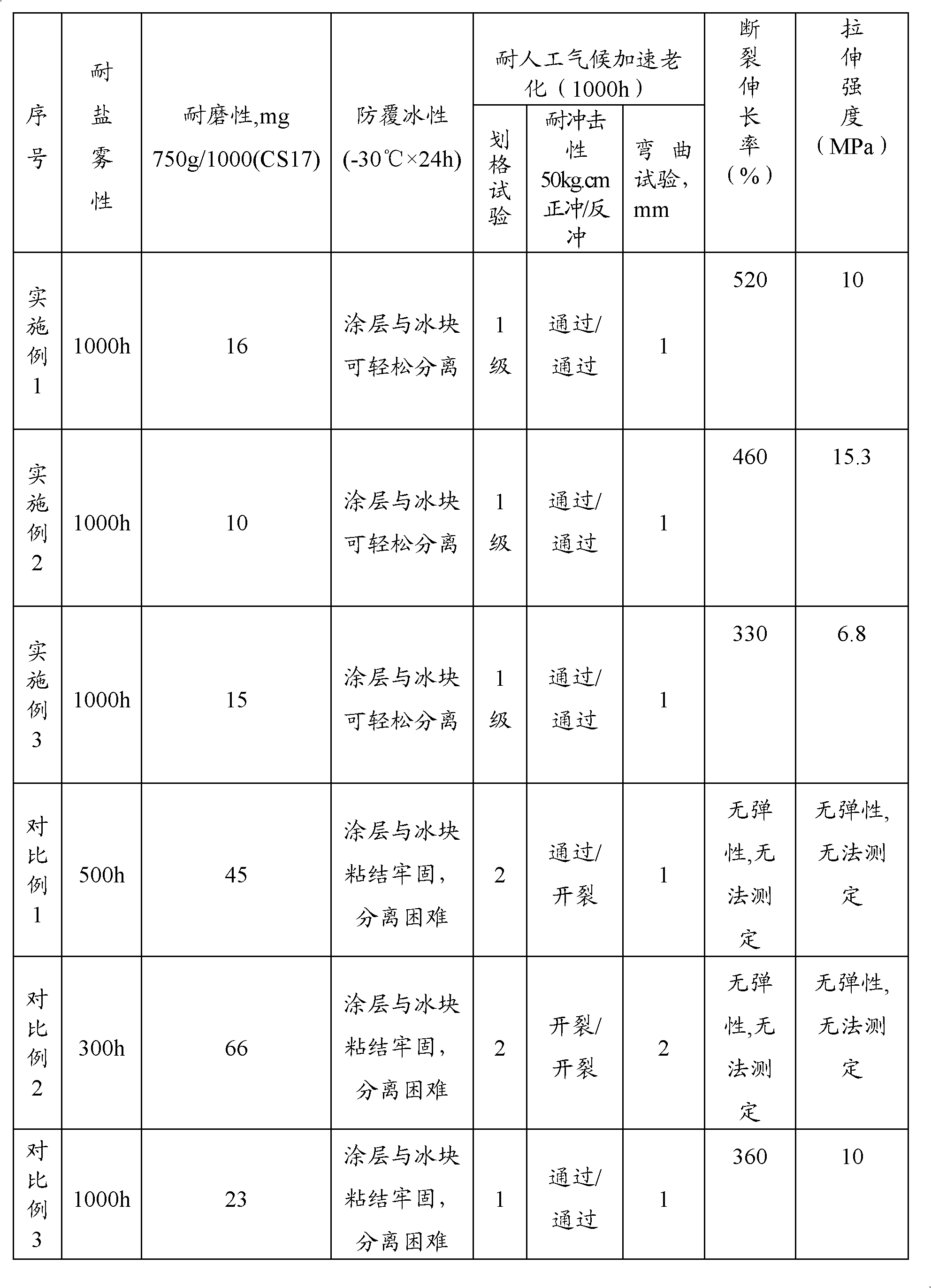

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides an antiseptic wear-resisting freezing adhesion-resisting one coat paint which comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 10-40% of isocyanate, 30-75% of amine terminated polyether, 1-15% of fluorine-containing siloxane and 5-25% of anhydrous butylacetate; and the component B comprises the following materials in percentage by weight: 15%-55% of steric hindrance type alkyl secondary amine, 1%-15% of nano freezing adhesion-resisting material, 10%-55% of pigment and filler, 0.5%-2.5% of dispersing agent, 0-2% of thixotropic agent, 0-3% of ultraviolet absorber and 5%-30% of solvent. The antiseptic wear-resisting freezing adhesion-resisting one coat paint provided by the invention is double-component paint comprising a curing agent component and an auxiliary component; and a spraying process is mainly adopted, so that the formed functional coating has the advantages of good antiseptic effect, abradability and freezing adhesion resistance, thus the paint is especially suitable for occasions in which requirements on wear-resistance, corrosion resistance and freezing adhesion resistance are high, such as heavy-duty vehicle coating, wind turbine blades and the like.

Description

A kind of anti-corrosion, wear-resistant, anti-freezing, anti-freeze, sticky bottom and surface all-in-one coating and preparation method thereof technical field The invention relates to the field of coatings, in particular to an anti-corrosion, wear-resistant, anti-freezing, anti-freezing and bottom-surface-integrated coating and a preparation method thereof. Background technique At present, most of the existing domestic anti-corrosion coating systems use primers, intermediate paints, top coats or composite anti-corrosion coating systems of primers and top coats. The main function of the primer is to lay a good foundation on the substrate, which has good adhesion to the substrate and has anti-rust performance; the main function of the intermediate paint is to increase the film thickness, so as to play a more effective shielding effect, and to make the The surface is smooth, which is conducive to topcoat coating; the main function of the topcoat is to prevent harmful corro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/08C09D5/08C09D7/12C08G18/50

Inventor 章卫国彭时贵刘雄鹰

Owner ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com