Matching device for dyeing machine and cloth dyeing method

A technology of dyeing machine and dye liquor, applied in textile processing machine accessories, equipment configuration for processing textile materials, textile and paper making, etc. Cloth effect, low operating cost, and the effect of increasing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

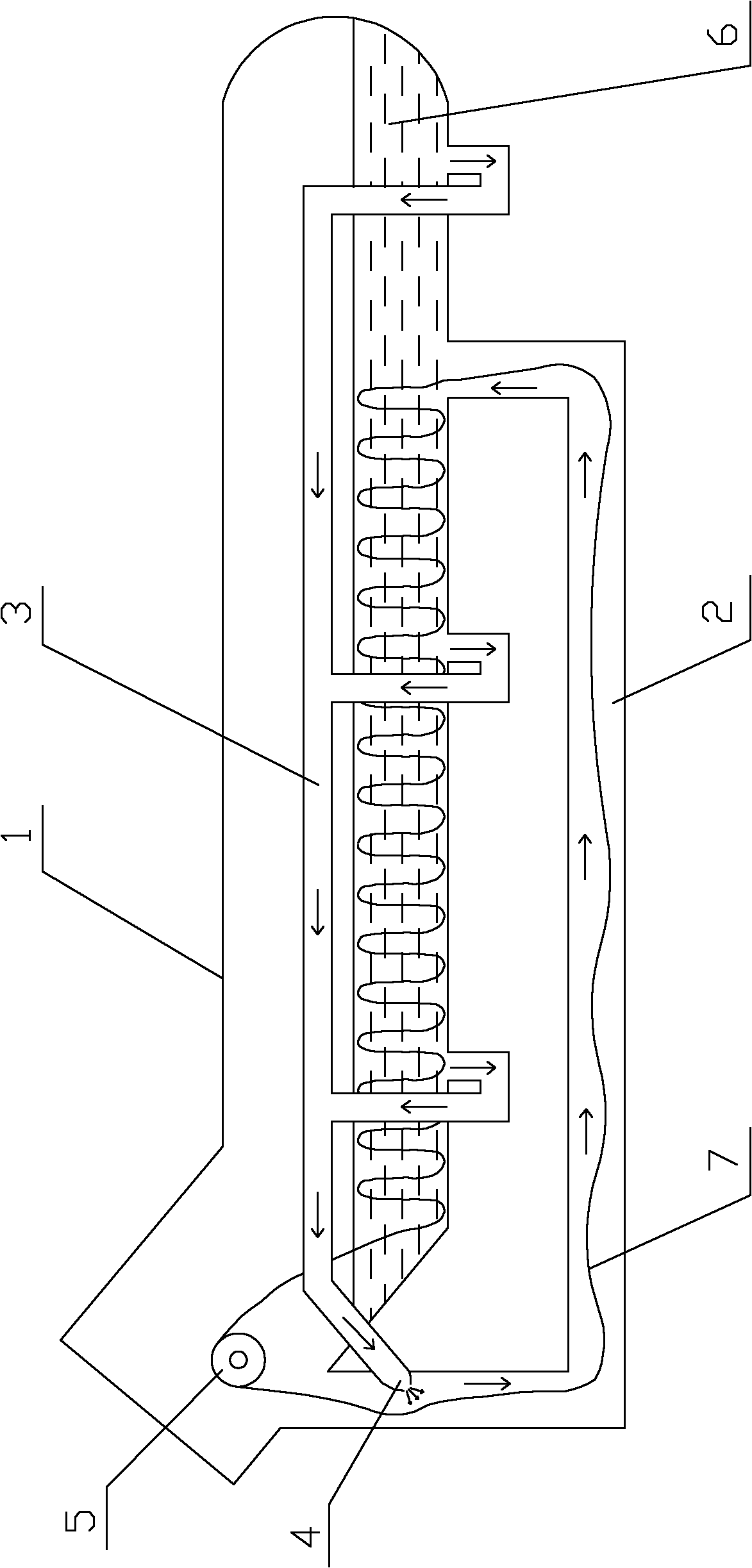

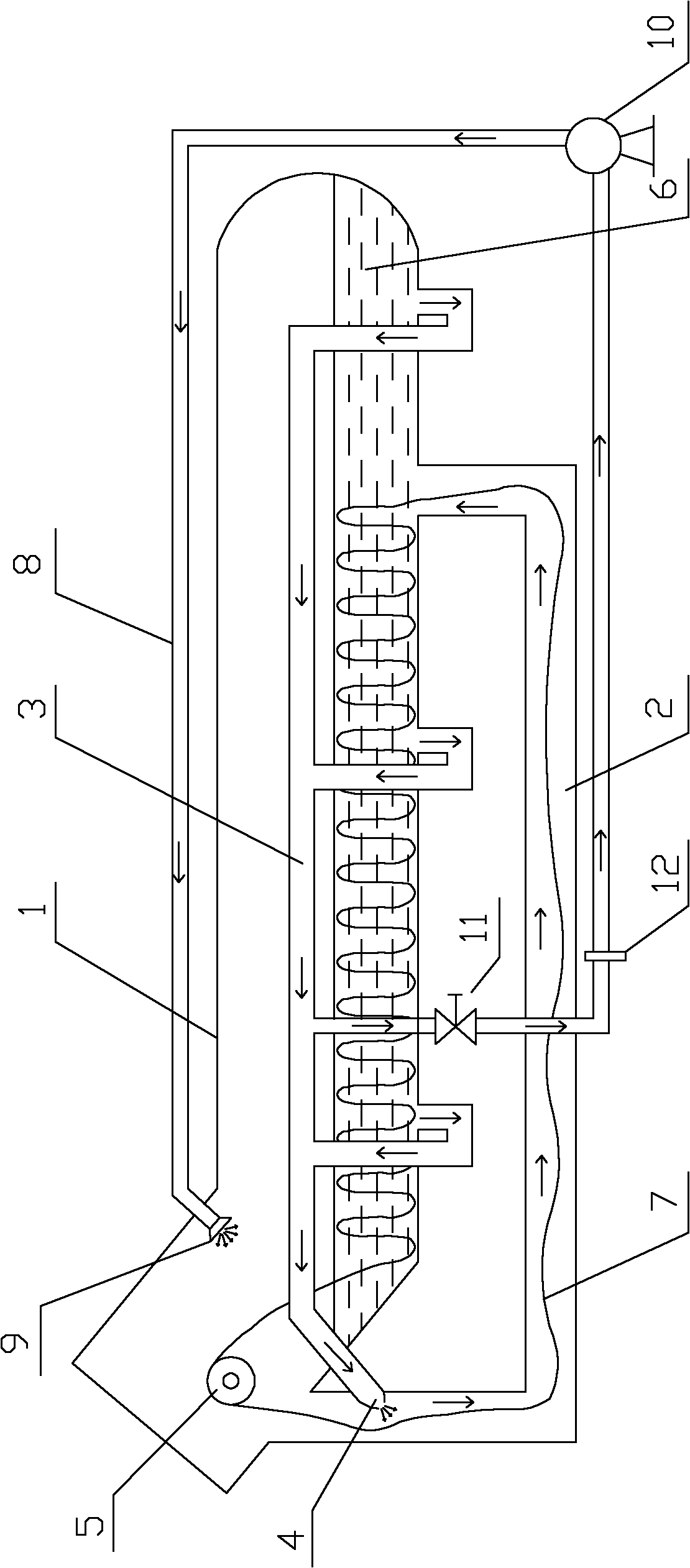

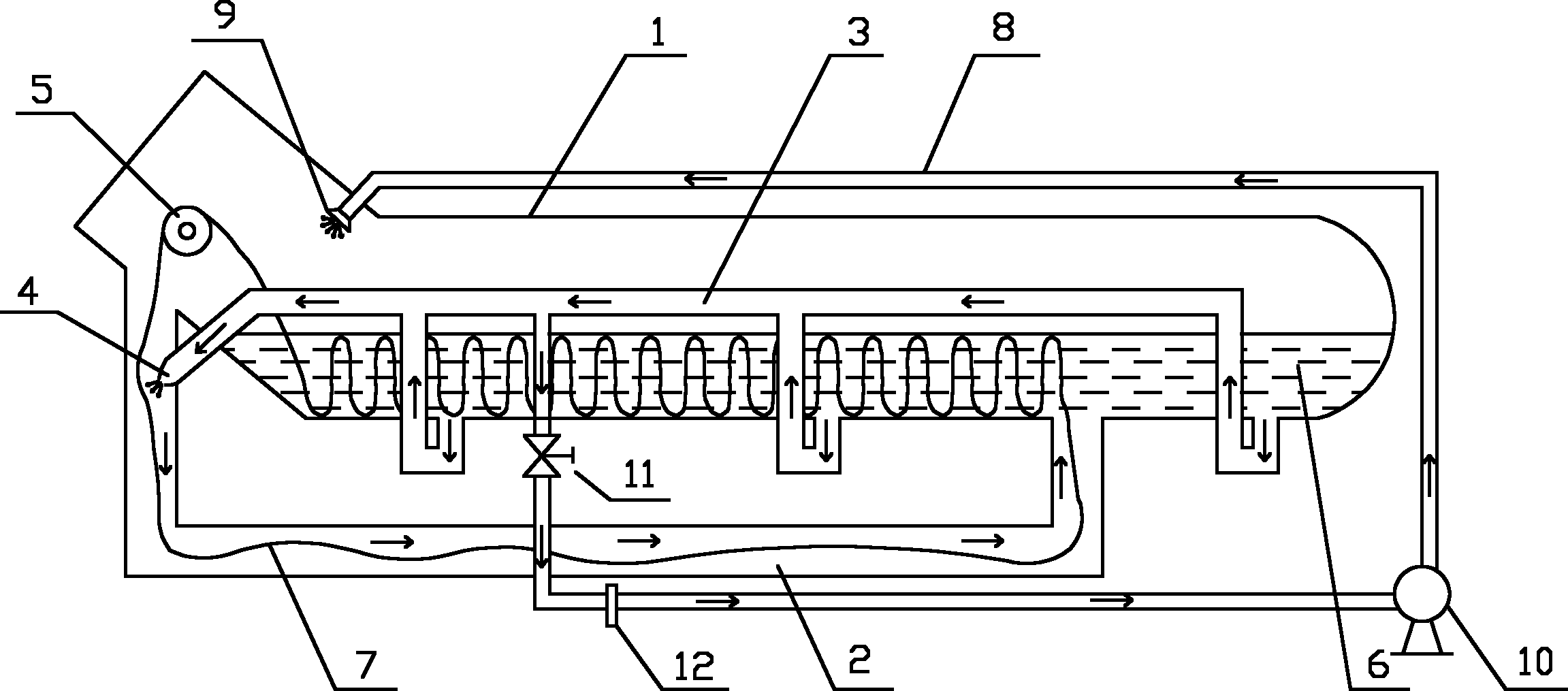

[0018] The dyeing machine mentioned in the present invention is a dyeing machine that uses the injection of dye liquor to propel the cloth. The supporting device of the dyeing machine provided by the present invention includes a spray system, and the spray system is set to use the dye liquor inside the dyeing machine and Spray it where the cloth is not running smoothly due to the presence of foam.

[0019] In the observation of dyeing cloth with existing dyeing machines, it is found that when the cloth is completely immersed in the dye solution, it is not easy to generate foam; and when the cloth is out of the dye solution, that is, the combination position of the cloth and the dye solution , especially prone to foam, because the existence of these foams makes the cloth lifting roller slip, and the cloth cannot run smoothly. Below the cloth roller, that is, the position where the cloth leaves the dye liquor.

[0020] Since the dye needs to be extracted from the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com