Silicon oxide and iron oxide composite material and synthesis method thereof

A composite material and a synthesis method technology, which are applied in the field of silicon oxide-containing composite materials and synthesis thereof, can solve the problems of complex preparation method and high cost, and achieve the effect of simple and easy synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: Preparation of different pH buffers

[0046] Configuration of pH4.5 buffer solution: Take 18g of sodium acetate and 9.8mL of glacial acetic acid, dilute with distilled water to a total volume of 1000mL.

[0047] The configuration of pH4.8 buffer solution: mix 19.96g sodium dihydrogen phosphate and 99.8mL distilled water to form A solution; mix 10.14g citric acid and 101.4mL distilled water to form B solution; mix A and B solutions to obtain a buffer solution.

[0048] The configuration of pH 5.0 buffer solution: mix 20.6g sodium dihydrogen phosphate and 103mL distilled water to form A solution; mix 9.7g citric acid and 97mL distilled water to form B solution; mix A and B solutions to obtain a buffer solution.

[0049] Configuration of pH 5.2 buffer solution: Mix 21.44g sodium dihydrogen phosphate and 107.2mL distilled water to form A solution; mix 9.28g citric acid and 92.8mL distilled water to form B solution; mix A and B solutions to obtain a buffer.

...

Embodiment 2

[0052] Mix 10g of ferric chloride, 0.1g of sodium chloride, 2g of urea, and 100mL of distilled water, stir for 1 hour; then place it in a reaction kettle at 140°C for 12 hours; then wash the solid product with distilled water 4 times until neutral, and dry at 120°C 12h obtains iron oxide;

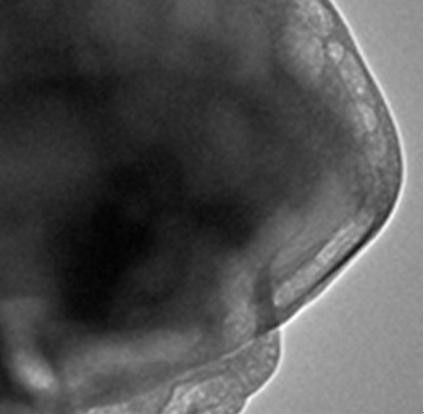

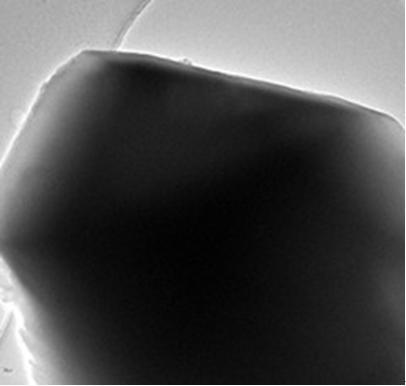

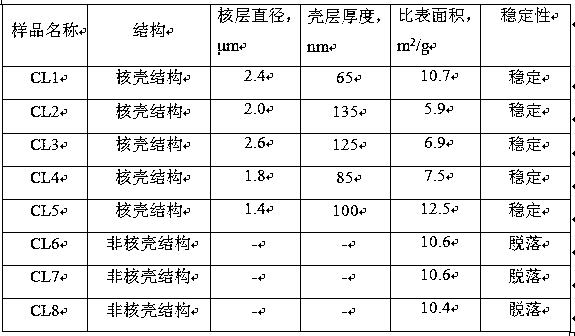

[0053] Take 1.82g of the above-mentioned iron oxide in 40mL of ethanol and stir for 0.5h, then ultrasonic treatment for 3h, the frequency of ultrasonic is 1MHz, and the power is 50W / L based on the volume of the solution; then put it in a water bath at 60°C, add 50mL of pH4. 8 buffer solution, add 1.3 mL tetraethyl orthosilicate dropwise under the stirring condition of 120 rpm, stir at the speed of 20 rpm for 5 h after the dropwise addition, and then place it in a water bath at 30 ° C for 12 h; The obtained product was washed 4 times with distilled water to neutrality, dried at 120°C for 12h, and heat-treated at 260°C for 3h to obtain SiO 2 / iron oxide composite material, the obtained sampl...

Embodiment 3

[0055] Mix 10g of ferric chloride, 0.06g of sodium chloride, 3g of urea, and 60mL of distilled water and stir for 0.2h; then place it in a reaction kettle at 170°C for 5h; then wash the solid product 4 times with distilled water until neutral, Dry for 12h to obtain iron oxide;

[0056] Take 2g of the above-mentioned iron oxide in 20mL of ethanol and stir for 0.2h, then sonicate for 2h, the frequency of the ultrasonic wave is 15KHz, the power is 100W / L based on the volume of the solution; then put it in a water bath at 70°C, add 12mL of pH5. Buffer solution, add 0.22mL tetraethyl orthosilicate dropwise under the stirring condition of 280 rpm; after the dropwise addition, stir at the speed of 50 rpm for 2h, then place it in a water bath at 25°C for 6h; The obtained product was washed 4 times with distilled water to neutrality, dried at 120°C for 12h, and treated at 280°C for 2h to obtain SiO 2 / iron oxide composite material, the obtained sample number is CL2, and the properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com