Soaking and coating airflow drying production line

An air drying and production line technology, applied in the field of processing, can solve the problems of affecting paper quality, low yield, uneven gluing on the surface of paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a detailed description of the technical solutions of the present invention through the accompanying drawings.

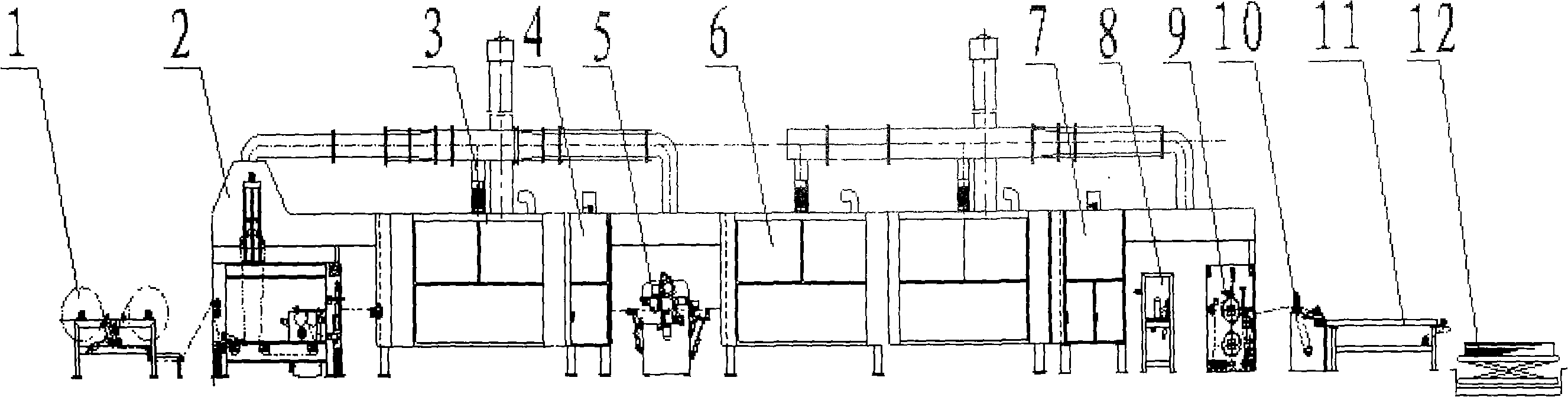

[0016] Such as figure 1 As shown, an impregnation coating airflow drying production line according to the present invention includes an uncoiling device 1, a primary dipping device 2, a primary drying device 3, a primary cooling device 4, a traction device 9, a paper cutting device 10 and a paper delivery device 11 , also includes a secondary coating device 5, which performs extrusion coating on the impregnated paper. The secondary coating device 5 can be divided into double extrusion according to the different requirements for the amount of glue on the front and back of the impregnated paper. There are three methods of overcoating, double anilox overcoating and upper extruded glue under anilox overcoating; the secondary drying device 6 dries the impregnated paper, and the secondary drying device 6 uses airflow drying technology and hot air ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com