Method for identifying fluctuation rub-impact fault of turbo generator set in real time

A turbogenerator set and identification method technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of high dependence on analysis work and the inability to achieve automatic online monitoring of fluctuating rubbing faults of turbogenerator sets, Analyzing and identifying issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

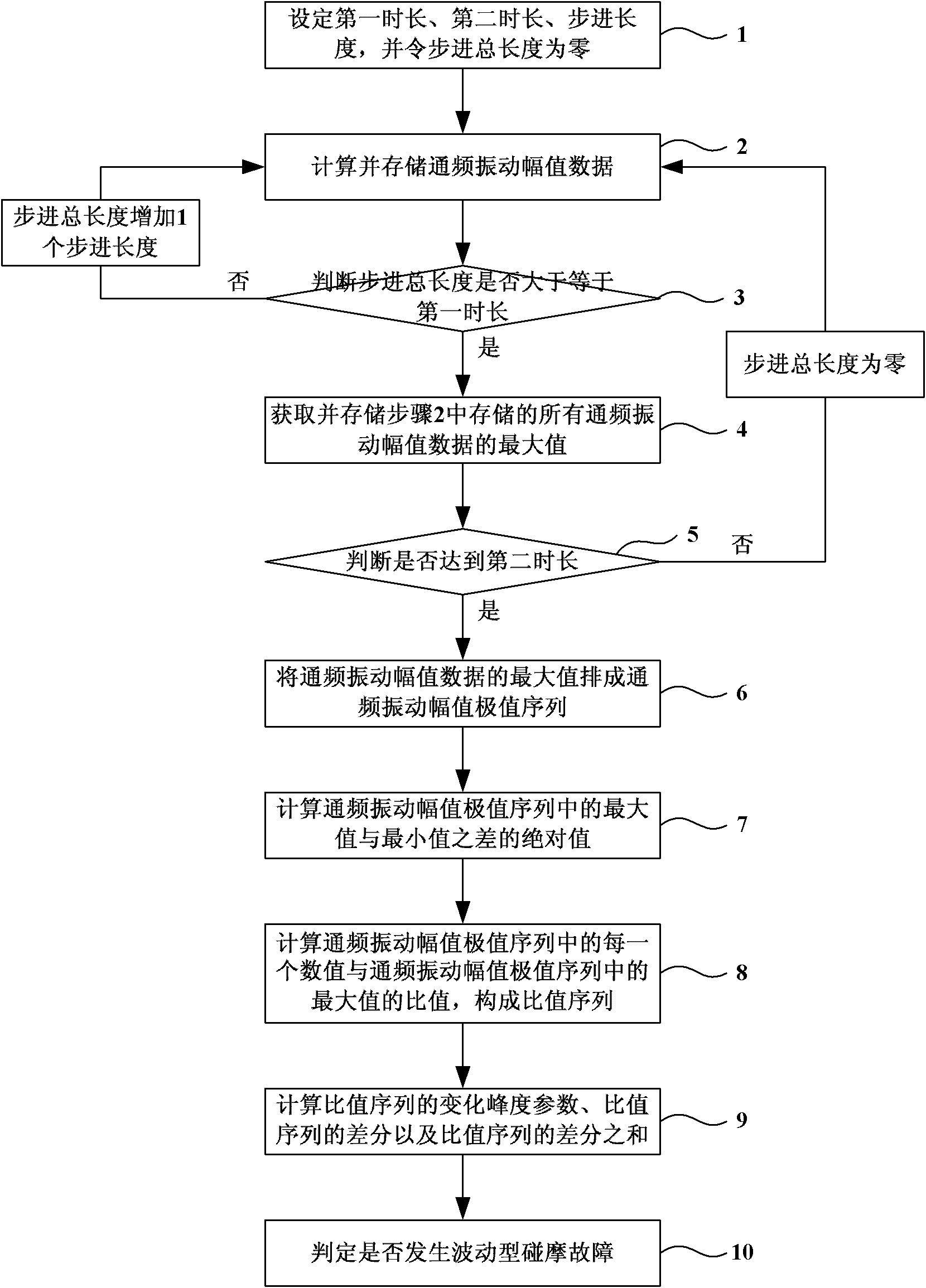

[0040] figure 1 It is a flow chart of the real-time identification method for fluctuating rubbing faults of a turbogenerator set. figure 1 Among them, the real-time identification method for fluctuating rubbing faults of turbogenerator sets includes the following steps:

[0041] Step 1: Set the first duration T 1 =100 seconds, the second duration T 2 =30000 seconds, the step length t=1 second, so that the total length of the step is t sum =0.

[0042] In the actual implementation process, the second duration T 2 Can take 40000≥T 2 ≥30000 seconds. In addition, in order to determine whether a fluctuating rubbing fault occurs in the shafting of the unit, the first set value D 1 =15μm, the second set value D 2 =1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com