Polarization maintaining double-clad optical fiber having helical structure and manufacturing method thereof

A technology of double-clad fiber and helical structure, which is applied in the direction of clad fiber, polarized fiber, multi-layer core/cladding fiber, etc., can solve the problem of low coupling efficiency of pump light, improve absorption efficiency, and improve extinction Compared with the effect of extinction ratio stability

Inactive Publication Date: 2011-06-15

BEIJING JIAOTONG UNIV

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to propose a polarization-maintaining fiber with a helical structure, the fiber core deviates from the center of the fiber, that is, to develop an eccentric helical structure polarization-maintaining double-clad doped fiber, which solves the problem of low pump light coupling efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

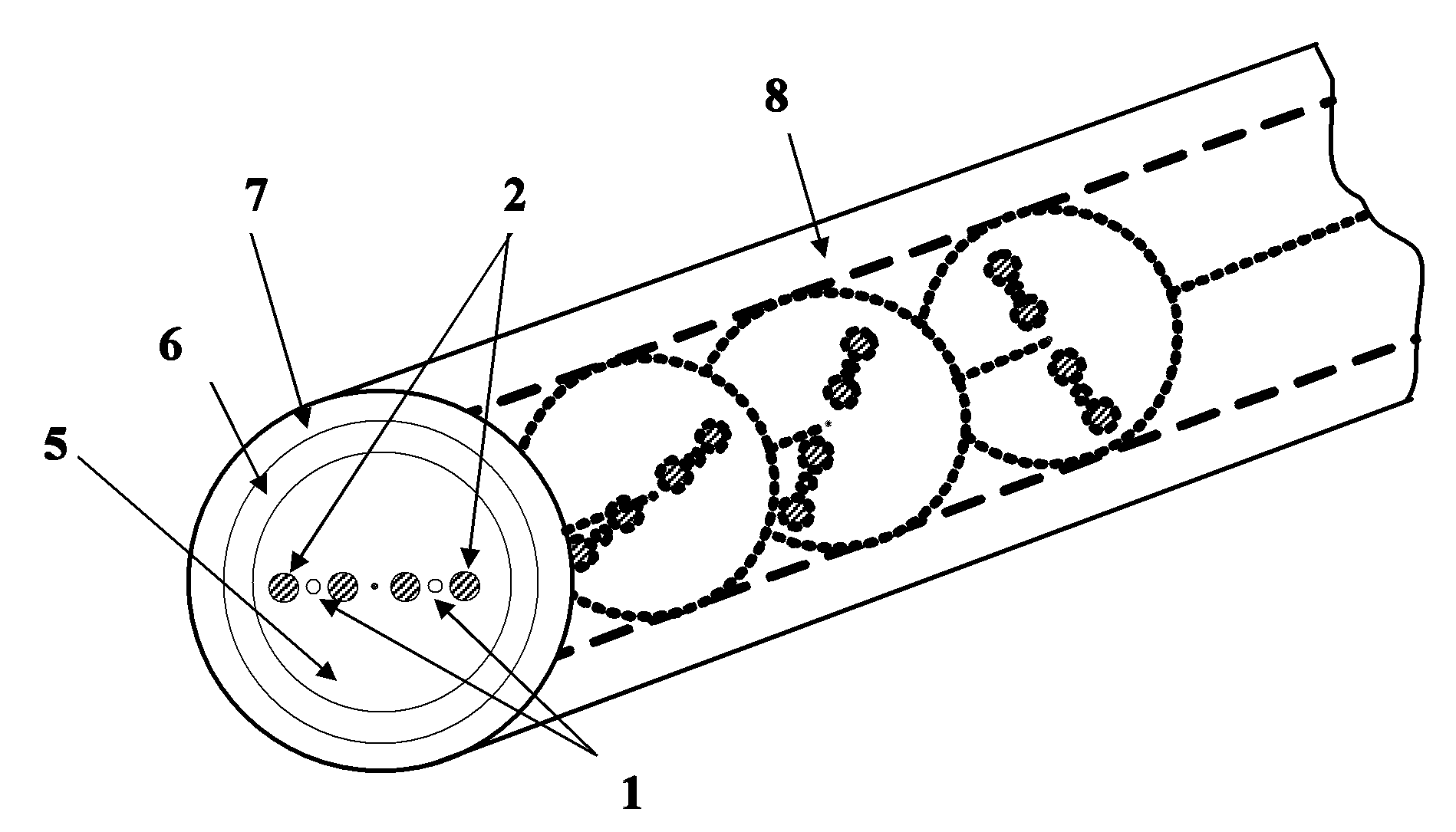

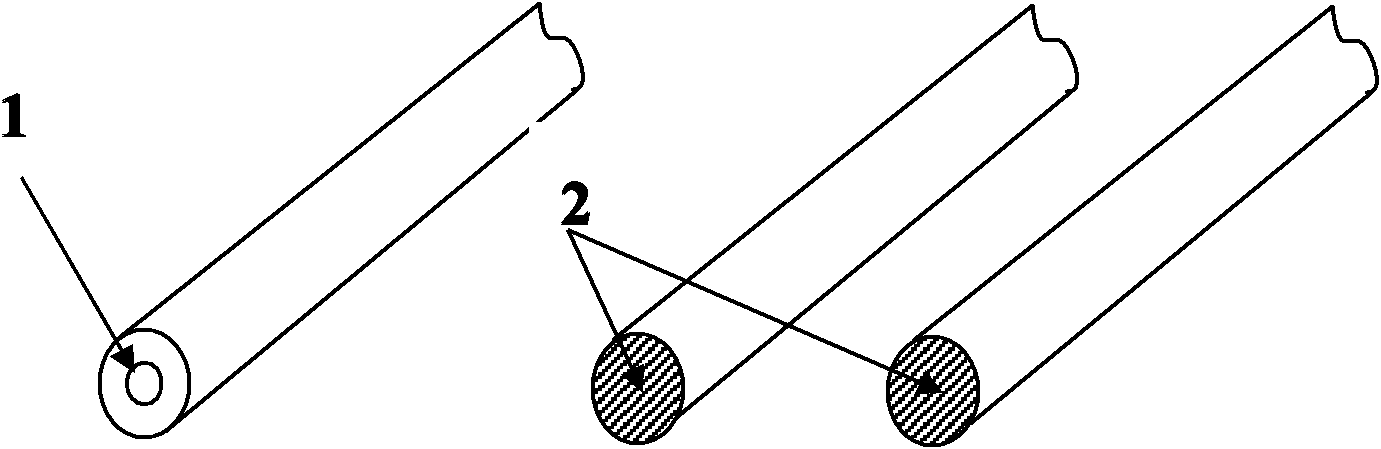

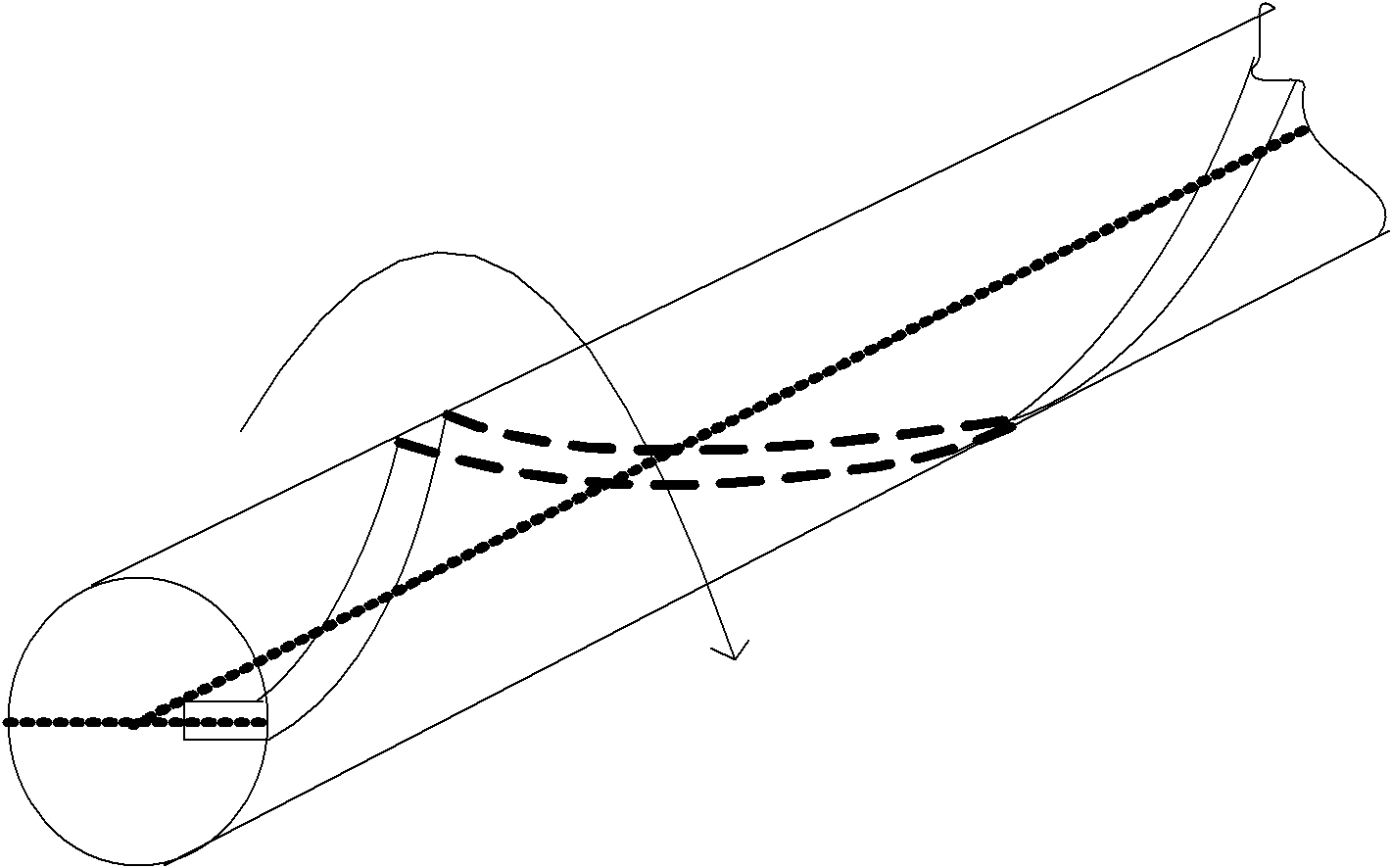

The invention discloses a polarization maintaining double-clad optical fiber having a helical structure and a manufacturing method thereof, and belongs to the technical field of optical fibers. The double-clad optical fiber consists of a fiber core, two stress areas which are symmetrically distributed on two sides of the fiber core, an inner clad layer, an outer clad layer and a coating layer. The technical manufacturing method comprises the steps of: manufacturing a core rod having a clad layer with a certain thickness, two B-doped rods and a plurality of pure quartz rods; selecting a larger-diameter high-purity quartz rod, and helically forming a rectangular groove on the quartz rod along an axial direction; embedding the core rod, the B-doped rods and the pure quartz rod which are softened at high temperature into the helical rectangular groove according to a sequence of a B-doped rod, the core rod, a B-doped rod and the pure quartz rod so as to form a preformed rod of the polarization maintaining optical fiber having the helical structure; and finally, drawing the preformed rod to obtain the polarization maintaining double-clad optical fiber having the helical structure. The optical fiber has a polarization maintaining characteristic and can break a helical effect of pump light, and the absorption efficiency of the optical fiber core on the pump light is improved.

Description

A polarization-maintaining double-clad optical fiber with helical structure and its manufacturing method technical field The invention relates to the field of optical fiber technology, in particular to a polarization-maintaining double-clad optical fiber with a helical structure and a manufacturing method thereof. Background technique Polarization maintaining fiber is a special fiber that maintains its linear polarization direction along the propagation direction of light. The application fields of polarization maintaining fiber are very extensive, such as: fiber laser, fiber optic gyroscope, fiber optic hydrophone, multiplexing coherent communication, polarization sensing, etc. In an ideal ordinary optical fiber, both the core and the cladding have a circular symmetric structure. If the influence of external factors on the optical fiber is not considered, for the incident linearly polarized light, the linearly polarized state is also maintained at the output end of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02B6/024C03B37/027G02B6/036

CPCC03B37/01217C03B2203/23C03B37/01234C03B2203/20C03B2203/31

Inventor 延凤平冯亭刘鹏李琦陶沛琳彭万敬梁骁苏尔慈田鹏飞孟涛

Owner BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com