Polarized light assembly with double metallic layer grating and manufacturing method thereof

A technology of bimetallic layer and manufacturing method, applied in the direction of polarizing element, etc., can solve the problems of incomplete compliance, great variation of the extinction ratio of polarizing components, and inability of high extinction ratio of polarizing components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

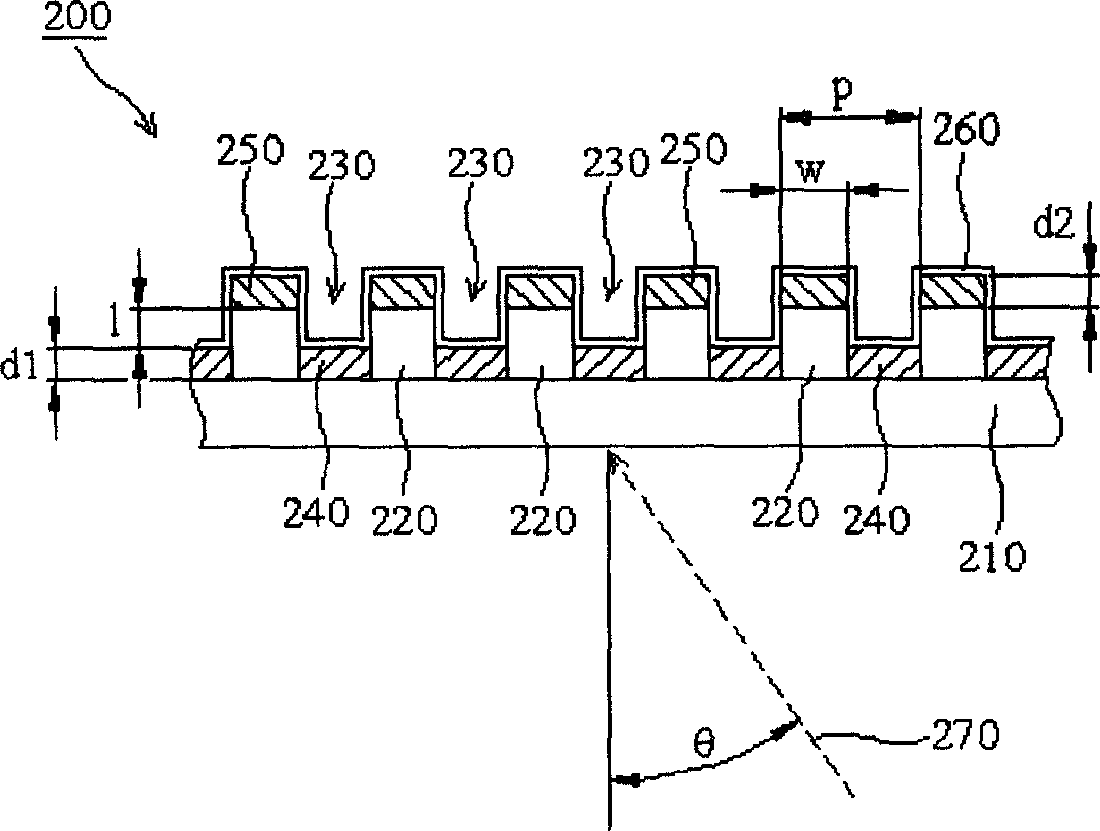

[0075] see figure 2In the polarizing component 200 of the present invention, the wavelength of the incident light 270 is 400-700nm (ie visible spectrum), the metal layers 240 and 250 are made of aluminum, the dielectric layer 220 is made of PMMA, and the substrate 210 is made of glass. The size conditions of each layer are: the thickness of the substrate 210 is 1000 μm, d1=d2=70nm, l=30nm, p=100nm, w=50nm and θ=0°. The reflectivity R of TE light under this condition TE and penetration rate T TE The relationship between the wavelength of visible light and the wavelength of visible light is as follows Figure 6A shown, while the reflectance R of TM light TM and penetration rate T TM The relationship between the wavelength of visible light and the wavelength of visible light is as follows Figure 6B shown.

[0076] Depend on Figure 6A and Figure 6B It can be seen that the transmittance T of TM light TM Most of them are above 70%, and the transmittance of TE light T T...

experiment example 2

[0078] see figure 2 The polarizing assembly 200 of the present invention. The experimental conditions are set as follows: the wavelength λ of the incident light 270 is 470nm, 550nm, 610nm, the metal layers 240 and 250 are aluminum, the dielectric layer 220 is PMMA, the substrate 210 is glass, the thickness of the substrate 210 is 1000 μm, d1=d2=70nm, l=30nm, p=100nm, w=50nm and θ=0°, 45°, 80°. The incident angle θ and extinction ratio T under this condition TM / T TE The experimental results are shown in Table 1:

[0079] Table 1

[0080]

[0081] It can be seen from Table 1 that the polarizing component of the present invention still has a relatively high extinction ratio (greater than 1000) when the incident light is at a large incident angle (80°).

experiment example 3

[0083] see figure 2 In the polarizing component 200 of the present invention, the wavelength of the incident light 270 is 400-700nm (ie visible spectrum), the metal layers 240 and 250 are gold, the dielectric layer 220 is PMMA, and the substrate 210 is glass. The size conditions of each layer are: the thickness of the substrate 210 is 1000 μm, d1=d2=70nm, l=30nm, p=180nm, w=90nm and θ=0°. The reflectance R of TE light under this condition TE and penetration rate T TE The relationship between the wavelength of visible light and the wavelength of visible light is as follows Figure 7A shown, while the reflectance R of TM light TM and penetration rate T TM The relationship between the wavelength of visible light and the wavelength of visible light is as follows Figure 7B shown.

[0084] Depend on Figure 7A and Figure 7B It can be seen that the transmittance T of TM light TM Most of them are above 70%, and the transmittance of TE light T TE It is almost zero (the act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com