Multi-core polarization maintaining fiber and manufacturing method thereof

A polarization-maintaining optical fiber and manufacturing method technology, applied in the direction of polarized optical fiber, clad optical fiber, manufacturing tools, etc., can solve the problems of not having polarization-maintaining characteristics, and achieve the effect of high transmission characteristics, excellent polarization characteristics, and large capacity

Inactive Publication Date: 2011-06-15

BEIJING JIAOTONG UNIV

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the usual sense, a multi-core fiber refers to an optical fiber composed of a group of axially parallel multiple fiber cores placed in an ordinary fiber cladding. This multi-core fiber is processed by introducing light into multiple cores. Transmission, each fiber core has the transmission characteristics of ordinary single-core fiber, but basically does not have polarization maintaining characteristics

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

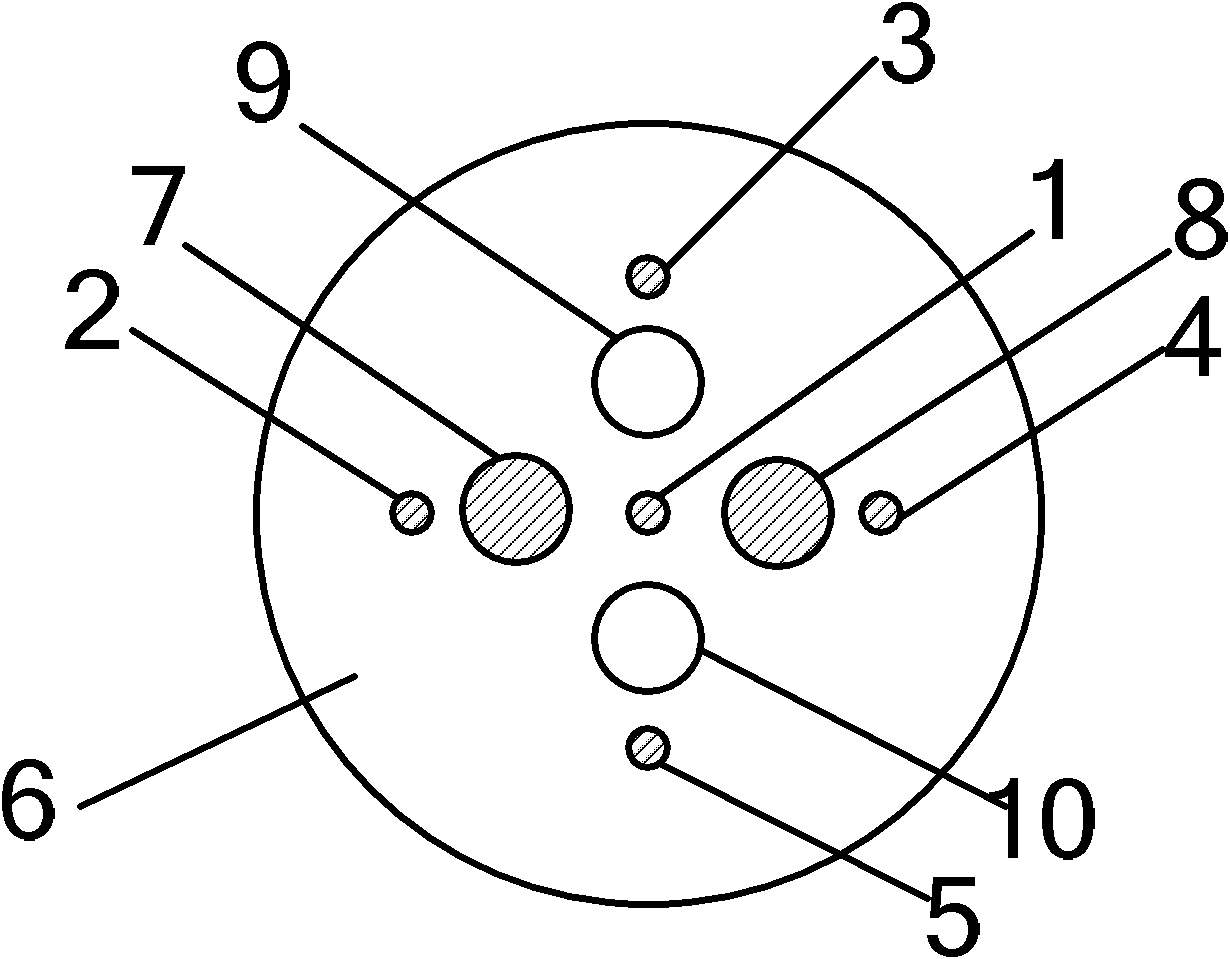

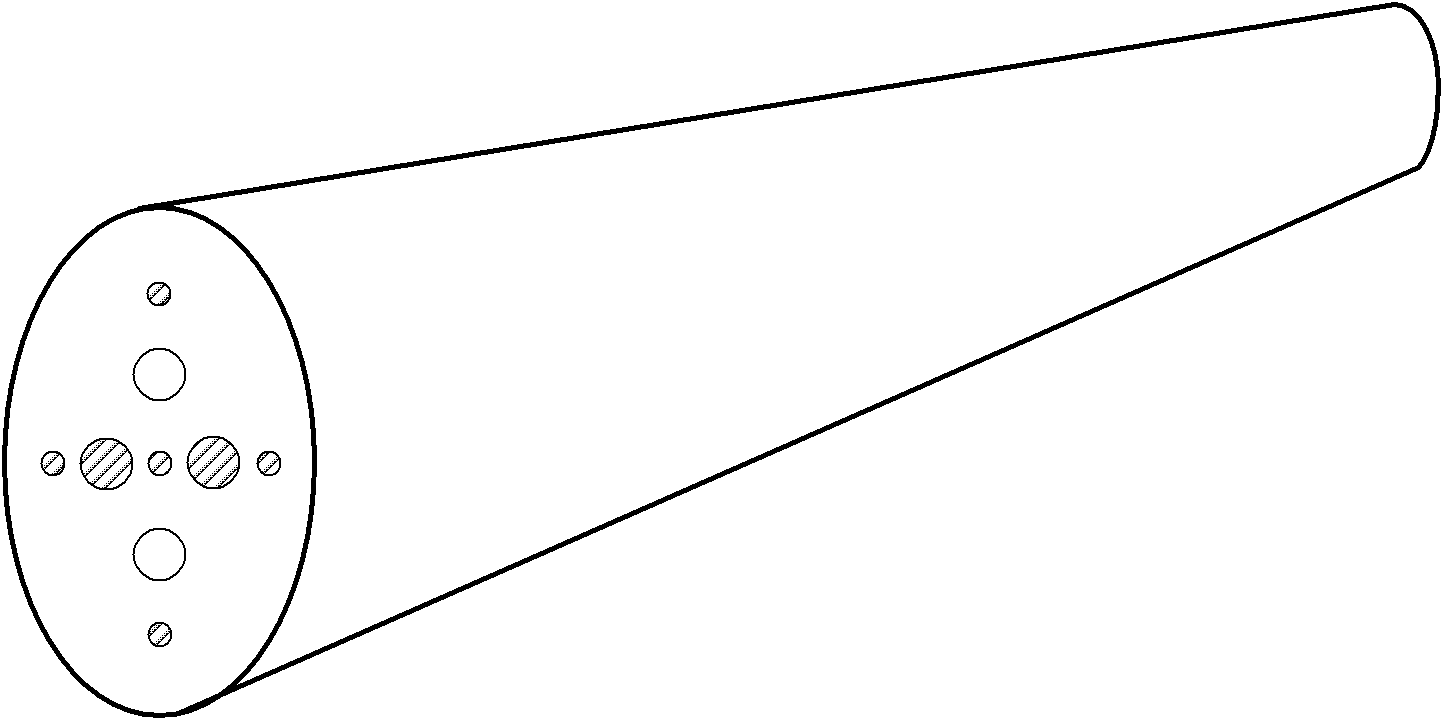

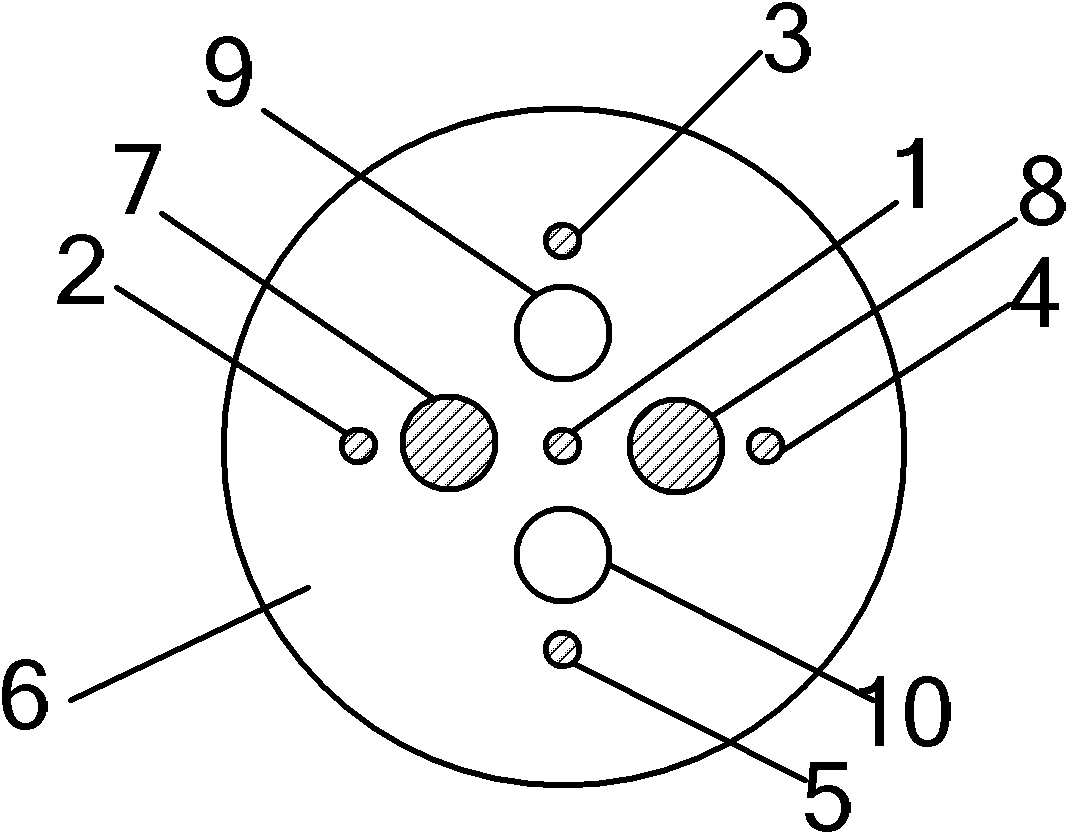

The invention relates to a multi-core polarization maintaining fiber and a manufacturing method thereof. The multi-core polarization maintaining fiber comprises: a pure quartz cladding, five fiber cores, two stress boron rods and two round holes. On the cross section of the multi-core polarization maintaining fiber, one fiber core is positioned in a circle centre, and the rest four fiber cores are positioned on the same circumference and distributed uniformly. The two stress boron rods and the two round holes are positioned in the same circumference and distributed alternatively. The multi-core polarization maintaining fiber and the manufacturing method thereof ensure that each fiber core has high polarization maintaining characteristics, so the fiber can meet large-capacity transmission and has high optical transmission quality.

Description

Multi-core polarization maintaining fiber and manufacturing method thereof Technical field The invention relates to a polarization maintaining optical fiber, in particular to a multi-core polarization maintaining optical fiber and a manufacturing method thereof. Background technique Polarization-maintaining fiber is a special fiber developed in the 1980s. Because of its excellent polarization-maintaining characteristics, its applications are extremely wide, including high-precision fiber optic gyroscopes, multiplexed coherent communications, polarization sensing, and fiber lasers. Polarization-maintaining fibers include stress-type birefringent polarization-maintaining fibers, geometrical polarization-maintaining fibers, and waveguide-type polarization-maintaining fibers. Stress-type birefringence polarization-maintaining fibers mainly include panda-type polarization-maintaining fibers, elliptical-clad polarization-maintaining fibers and bow-tie-type polarization-maintaining f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B6/024G02B6/02C03B37/025

Inventor 延凤平陶沛琳李琦刘鹏冯亭田鹏飞谢燕平梁骁孙欣欣

Owner BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com