Method for sticking massively produced simple lenses and metal brackets

A metal bracket and simple lens technology, applied in installation, optics, instruments, etc., can solve the problems of dislocation of the metal bracket and the simple lens, adhesive glue flowing to the lens, low operation efficiency, etc., achieving simple structure, easy operation, The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Method steps of the present invention are as follows:

[0017] a. Place the metal bracket in the through hole of the positioning jig, and apply glue evenly on the upper surface.

[0018] B. Then place the lens in the slot of the positioning jig. At this time, the metal bracket is on the bottom and the lens is on the top for complete positioning.

[0019] c. Baking;

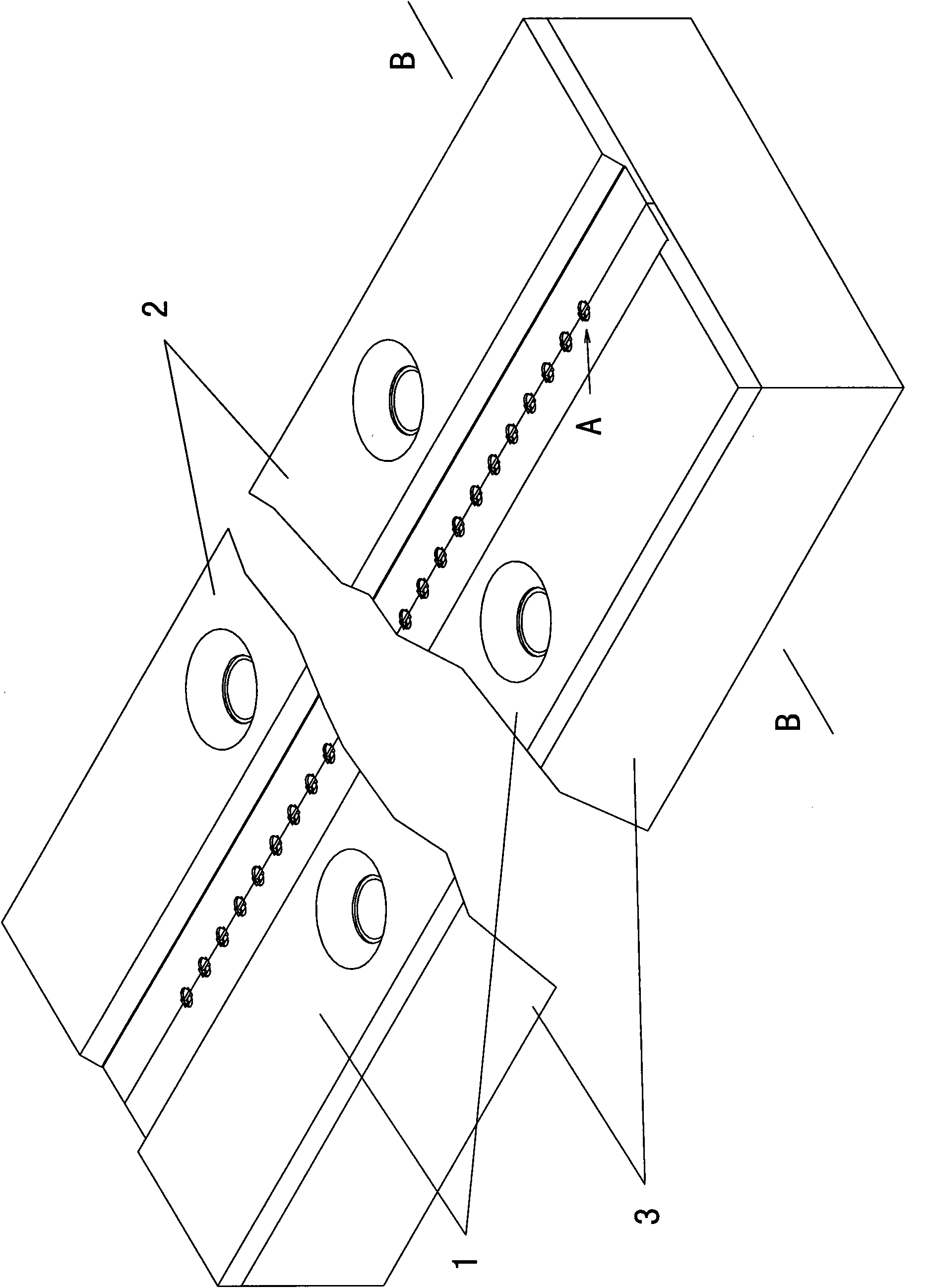

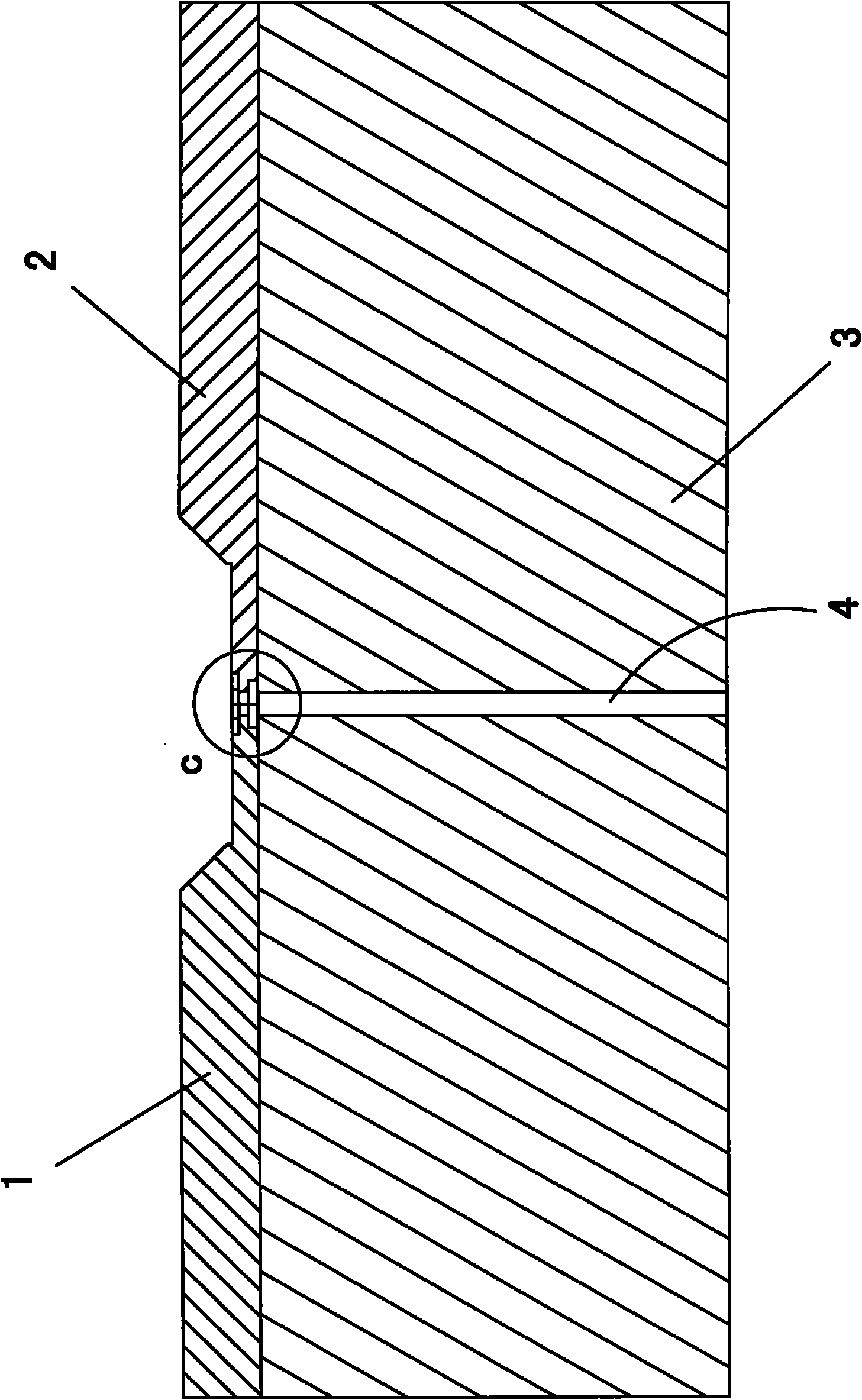

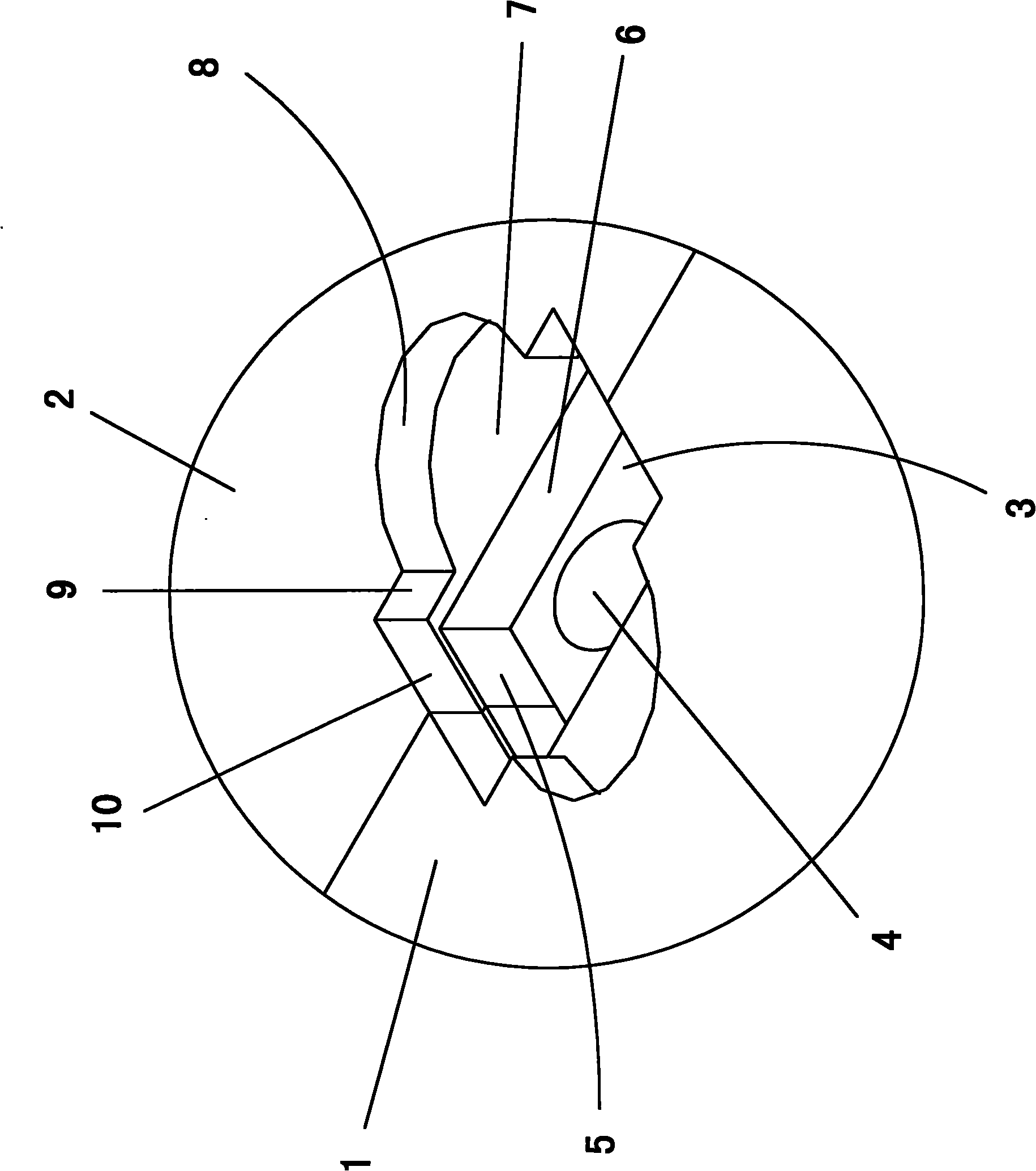

[0020] The concrete structure of above-mentioned positioning jig is: as figure 1 , 2 , 3, and 4 show: there is a cuboid base plate 3, and a plurality of through holes 4 arranged in a straight line are processed on the longitudinal center line of the base plate 3.

[0021] There are symmetrically arranged left upper plate 1 and right upper plate 2 on the bottom plate 3, and the thickness dimension of the left upper plate 1 and right upper plate 2 close to each other is smaller than the outer thickness dimension.

[0022] There is a slot A for placing a simple lens at the joint surface where the upper lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com