Laser mirror assembly

A mirror and assembly technology, applied in laser welding equipment, optics, optical components, etc., can solve problems such as reducing production efficiency, and achieve the effect of improving efficiency, convenient operation, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

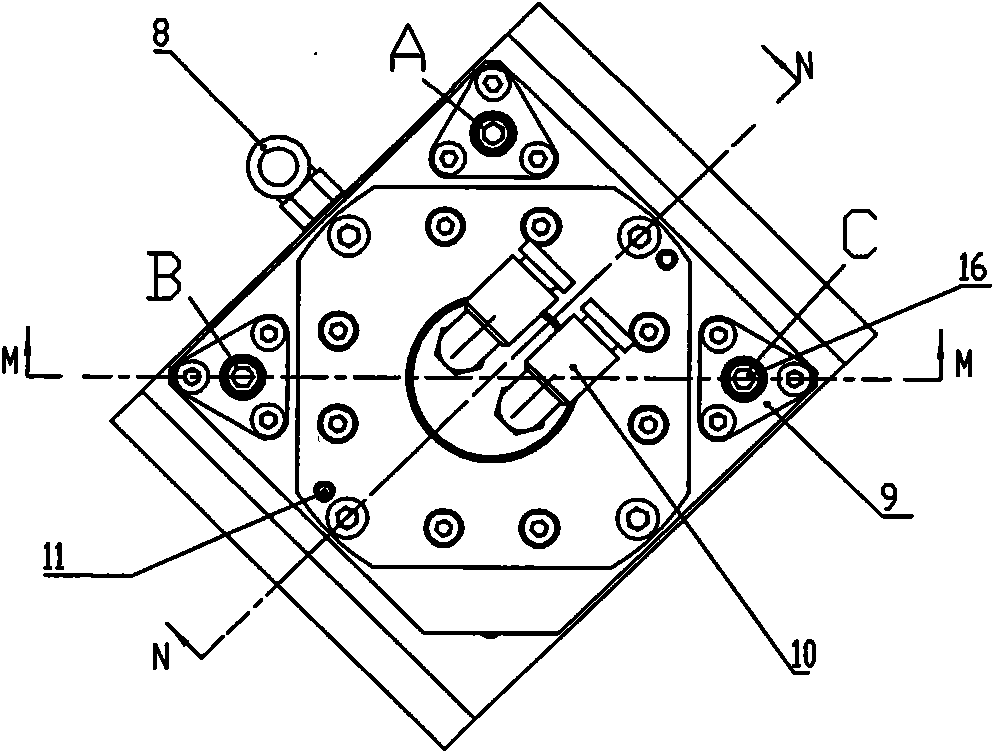

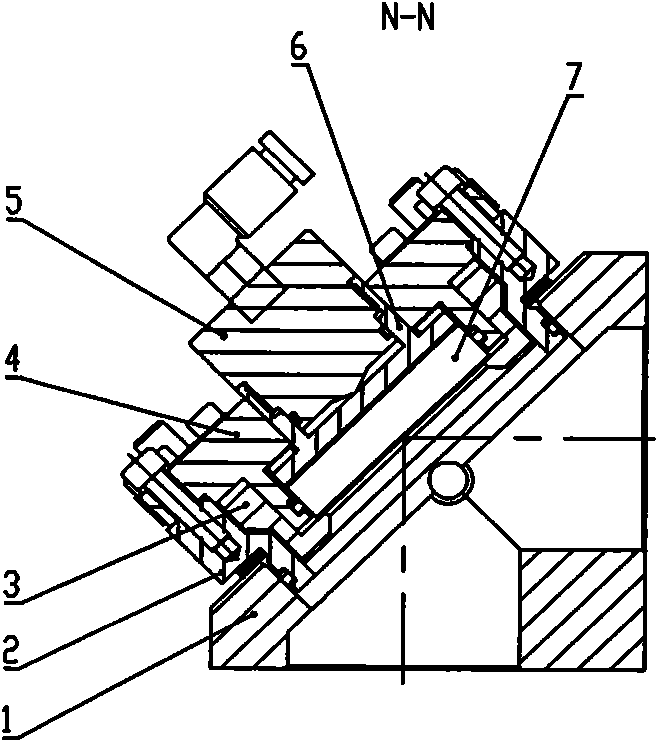

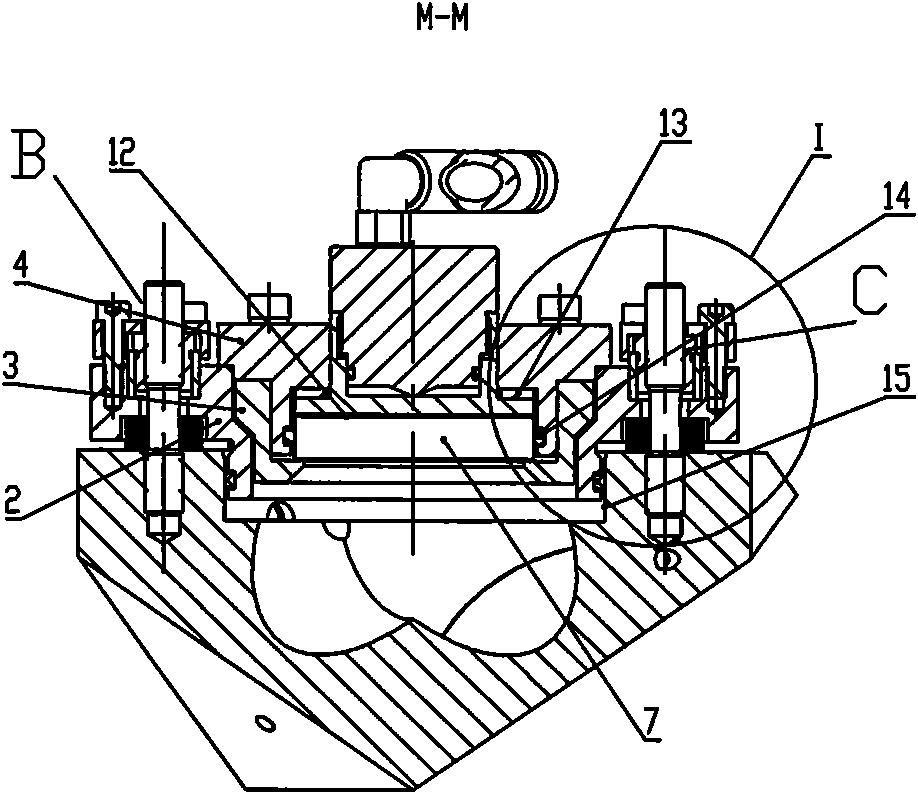

[0026] The present invention as Figure 1-5 As shown, it includes a triangular block-shaped and hollow seat body 1, and two adjacent square surfaces of the seat body 1 are respectively provided with large light-transmitting holes. An adjustment assembly connected to the installation hole 15 with adjustable coaxiality, and an installation assembly detachably connected with the adjustment assembly; the lens 7 is fixedly connected in the installation assembly.

[0027] The adjustment assembly includes a lens adjustment block 2 and three sets of adjustment connectors; the adjustment connectors include a fixed pressure block 9, an adjustment screw 16, an adjustment nut 17 and an adjustment spring 19. In order to further improve the accuracy of connection adjustment, additional Such as Figure 4 The spacer 18 shown; the center of the lens adjustment block 2 is provided with a step circle facing the mounting hole 15 of the seat body, the center of the step circle is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com