Method of forming vertical structure light emitting diode with heat exhaustion structure

A technology of light-emitting diodes and vertical structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of low yield of 2-inch wafers and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to solve the heat dissipation problem caused by the current pushing effect, there is an urgent need for a vertical light-emitting diode with a heat dissipation structure. As described below, embodiments of the present invention disclose a method for forming a vertical light emitting diode with a heat dissipation structure.

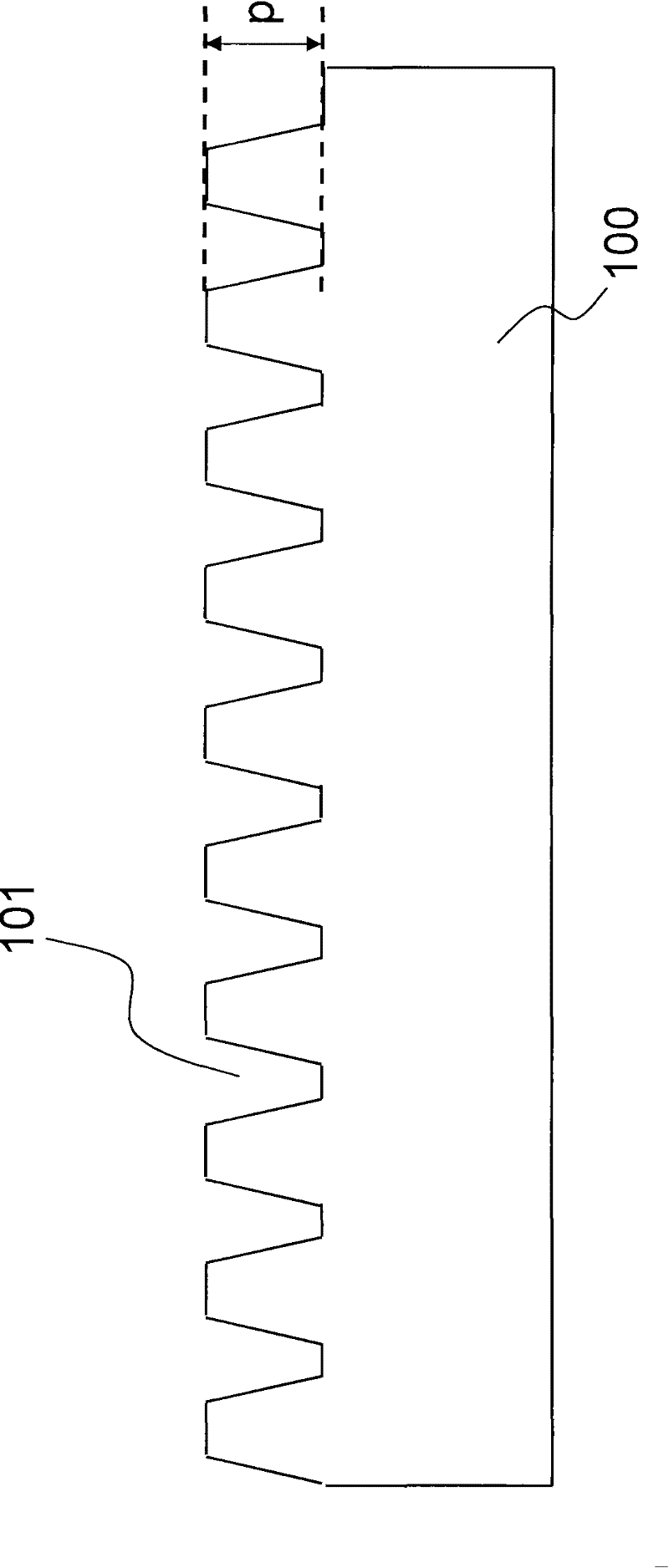

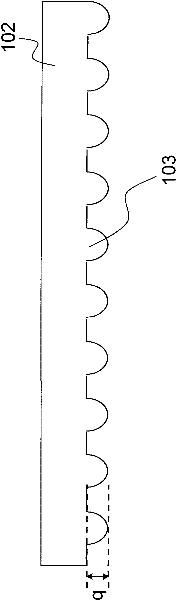

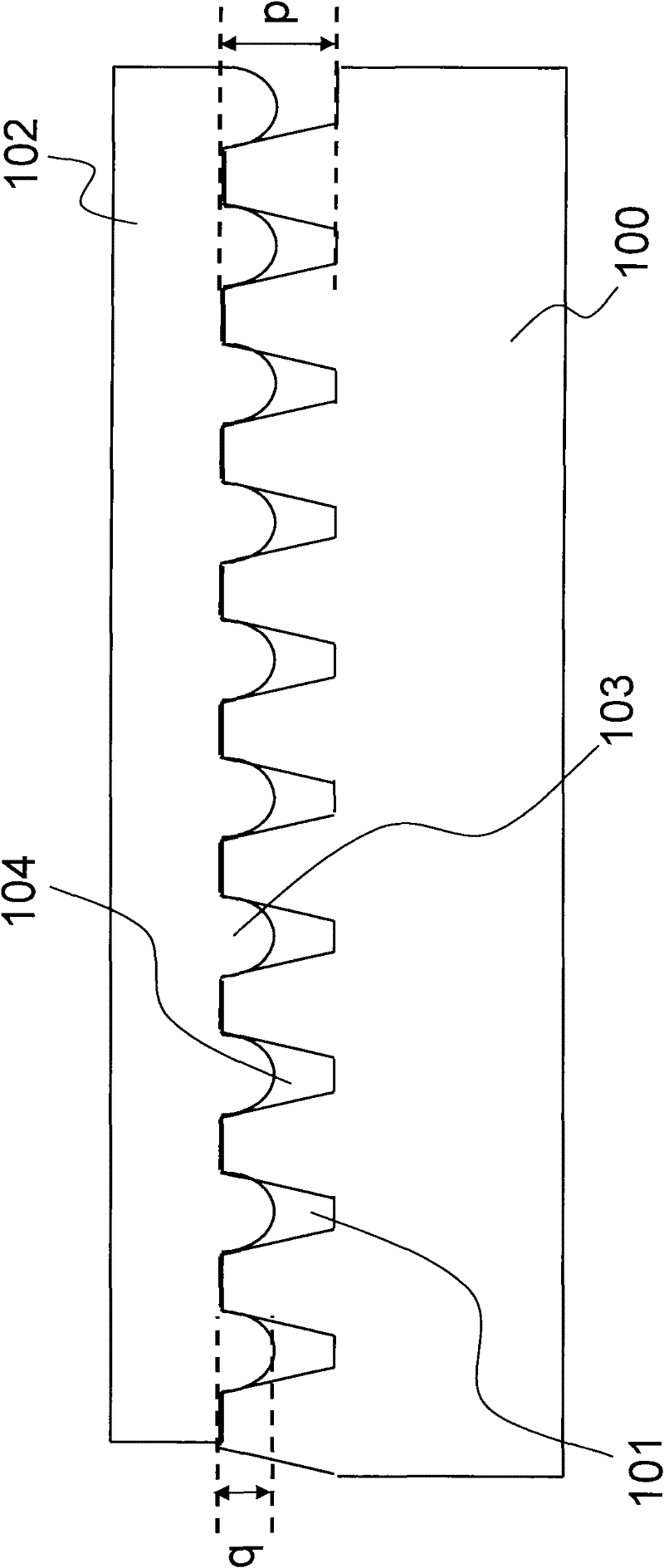

[0026] Figure 1 to Figure 9 The first embodiment of this case is shown. In this embodiment, firstly, a sapphire substrate 100 is provided. Thereafter, a plurality of recesses 101 are formed on the sapphire substrate 100 by a photoetching process, a wet etching process, or a dry etching process. The depth of the recess 101 is p, and the width of the recess is m. The buffer layer 102 formed on the sapphire substrate 100 has a plurality of protrusions 103 with a height q and a width n of the protrusions.

[0027] The convex portion 103 of the buffer layer 102 is housed in the concave portion 101 of the sapphire substrate 100 . Since the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com