Method and device for treating stator of large wind turbine with insulating varnish and device for baking insulating varnish on stator

A wind turbine and stator insulation technology, which is used in electromechanical devices, manufacturing motor generators, laying solid insulation, etc., can solve the problems of increasing materials, hidden dangers of motor operation safety, affecting product quality, etc. Reduced process time and energy consumption, the effect of reduced process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

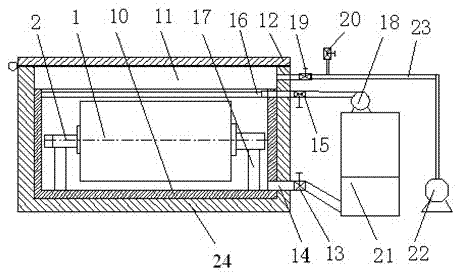

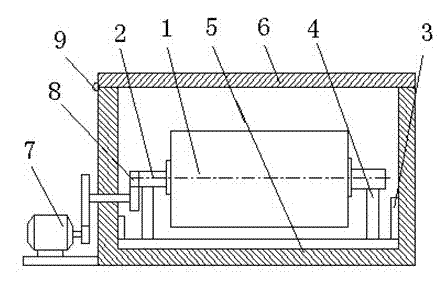

[0027] A large permanent magnet direct drive wind power generator stator insulation dipping treatment method, the insulation dipping treatment process method includes the following steps:

[0028] 1. According to the size of the inner hole of the motor stator, make a dummy shaft that can pass through the center hole of the stator and has a rotating shaft at both ends; there is also a mounting seat that matches the flange assembly surface of the motor stator on the dummy shaft ; And there are special lifting holes and rotary drive interfaces at both ends of the dummy shaft;

[0029] 2. Place the stator vertically on the worktable, install the dummy shaft with the flange assembly surface in the stator, and fix the mounting seat on the dummy shaft with the flange assembly surface in the motor stator, so that the stator is located in the middle of the dummy shaft. There are rotatable rotating shafts protruding from both ends;

[0030] 3. Clamp both ends of the dummy shaft with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com