Applicator for applying a sealing compound to an edge-raised seam and associated operating method

An operation method and technology of an applicator, which can be applied to devices for applying liquid to surfaces, coatings, liquid distribution, etc., can solve the problems of large required space, loss, increased investment costs, etc., so as to save construction space and save The effect of cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

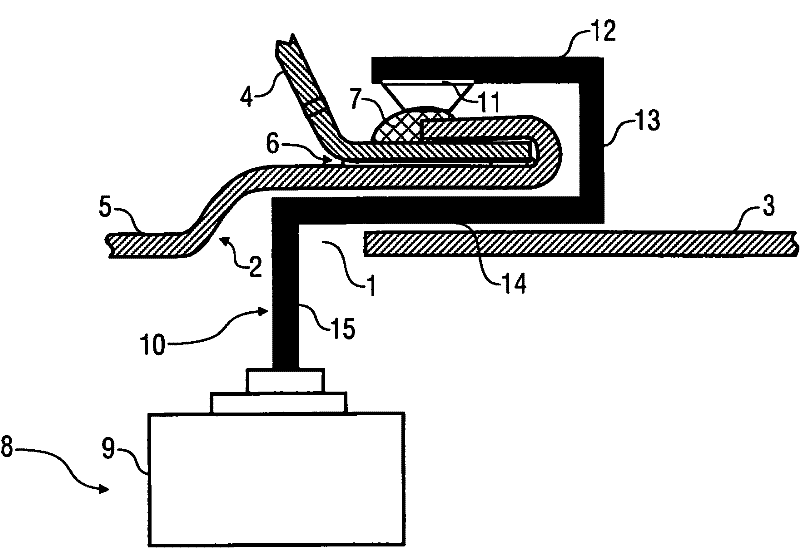

[0043] figure 1 The area of the gap 1 between the motor vehicle door 2 and the screen wing 3 (baffle) is shown. In the closed state shown in the figure, the motor vehicle door 2 and the screen wing 3 overlap to enhance the impact safety.

[0044] The motor vehicle door 2 has an inner panel 4 and a sheet metal panel 5 forming a flange around the curved edge of the inner panel 4 . In the region of the curved edges, the inner panel 4 is connected to the sheet metal panel 5 by means of an adhesive layer 6 . In this construction, the danger is that in the area of the flange seam, moisture will enter the gap between the bent edge of the inner panel 4 and the flanged edge of the sheet metal panel 5 and cause corrosion. The flange joint between the inner panel 4 and the sheet metal panel 5 is therefore sealed with a sealant 7 which is at right angles to the plane of the drawing along the entire length of the flange joint to prevent the penetration of moisture into the flange join...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com