Method for shifting the point of machining of a work piece and machine tool

A technology for processing positions and moving workpieces. It is used in metal processing machinery parts, metal processing, automatic control devices, etc. It can solve the problems of increased workspace, low dynamics, and high quality, and achieves low air pollution and high dynamics. , optimize the suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

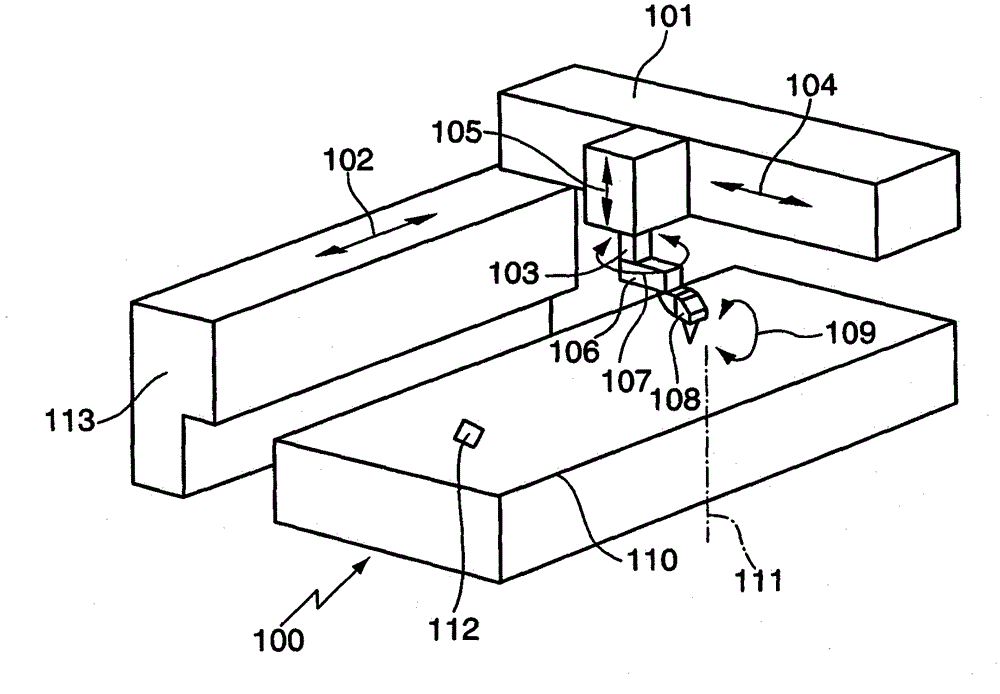

[0036] exist figure 2 A machine tool 100 is shown in which a cantilever beam 101 is movable in an axial direction 102 . The device 103 is movable in the axial direction 104 along the cantilever beam 101 . Device 103 is additionally movable in axial direction 105 . The x, y, z directions of the Cartesian coordinate system are determined by the axial directions 102 , 104 , 105 . Part 106 is rotatable in axial direction 107 . A tool 108 designed as a laser cutting head, which in turn is rotatable in an axial direction 109 , is arranged on the component 106 . The device causing the movement in one of the axial directions 102 , 104 , 105 , 107 or 109 is the tool axis and is responsible for the movement of the tool 108 relative to the workpiece carrier 110 . The workpiece holder 110 is arranged rotatably about a rotation axis 111 . The workpiece holder 110 is in particular arranged to be rotatable. The device that causes the workpiece support 110 to rotate about the axis of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com