End surface arc turning clamp

A fixture and arc-shaped technology, which is applied in the field of end-face arc-shaped turning fixtures, can solve the problems of inability to process arc-shaped end faces of workpieces, poor machining accuracy, time-consuming and laborious, etc., and achieve the goals of widening the processing range, reducing processing costs, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

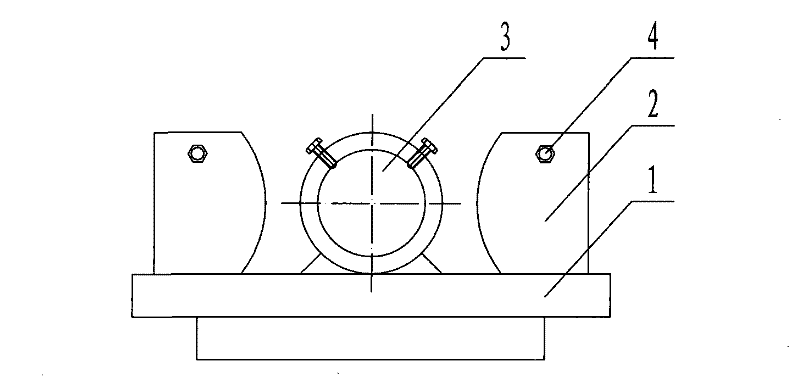

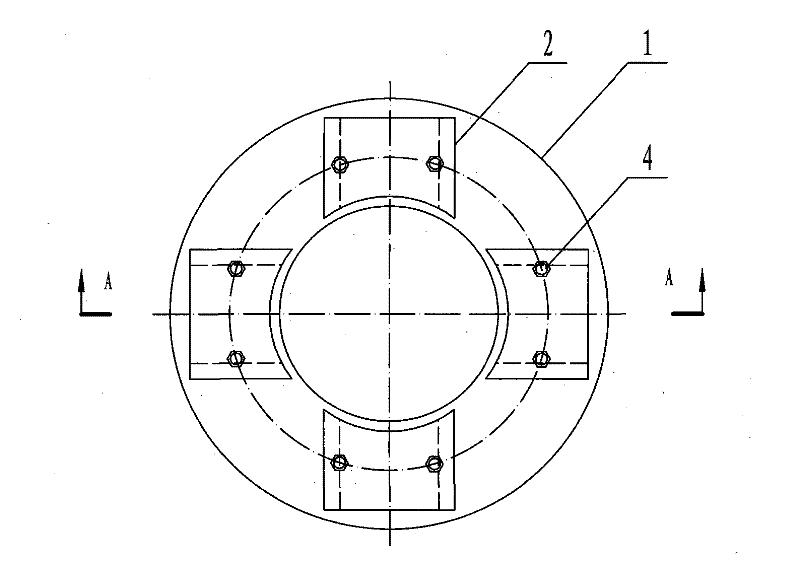

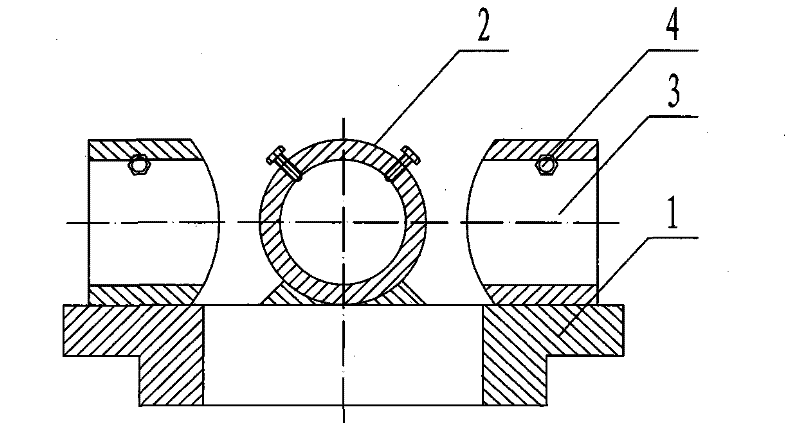

[0016] Attached below Figure 1-3 The end surface arc-shaped turning jig of the present invention will be described in detail below.

[0017] as attached Figure 1-3 As shown, the end face arc-shaped turning fixture of the present invention has a structure including a fixture base

[0018] 1. The clamp base 1 is in the form of a circular ring structure, its axial section is in a stepped structure, and the center line is perpendicular to the upper surface. On the upper surface of the fixture base 1, there are 4 round tube workpiece fixing seats 2 evenly distributed, and each round tube workpiece fixing seat 2 is provided with two workpiece fixing bolts 4, and each round tube workpiece fixing seat 2 is provided with Circular through holes 3, all circular through holes 3 have the same diameter, their centerlines are parallel to the upper surface of the fixture base 1 and have the same height and meet at the centerline of the circular fixture base 1, the above-mentioned circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com