Clamping method and clamping device for irregular non-metal workpiece

A clamping method and non-metal technology, applied in metal processing mechanical parts, metal processing equipment, positioning devices, etc., can solve the problem that the clamping method and device cannot complete the clamping operation, and achieve convenient material acquisition and clamping force distribution. Uniform, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments.

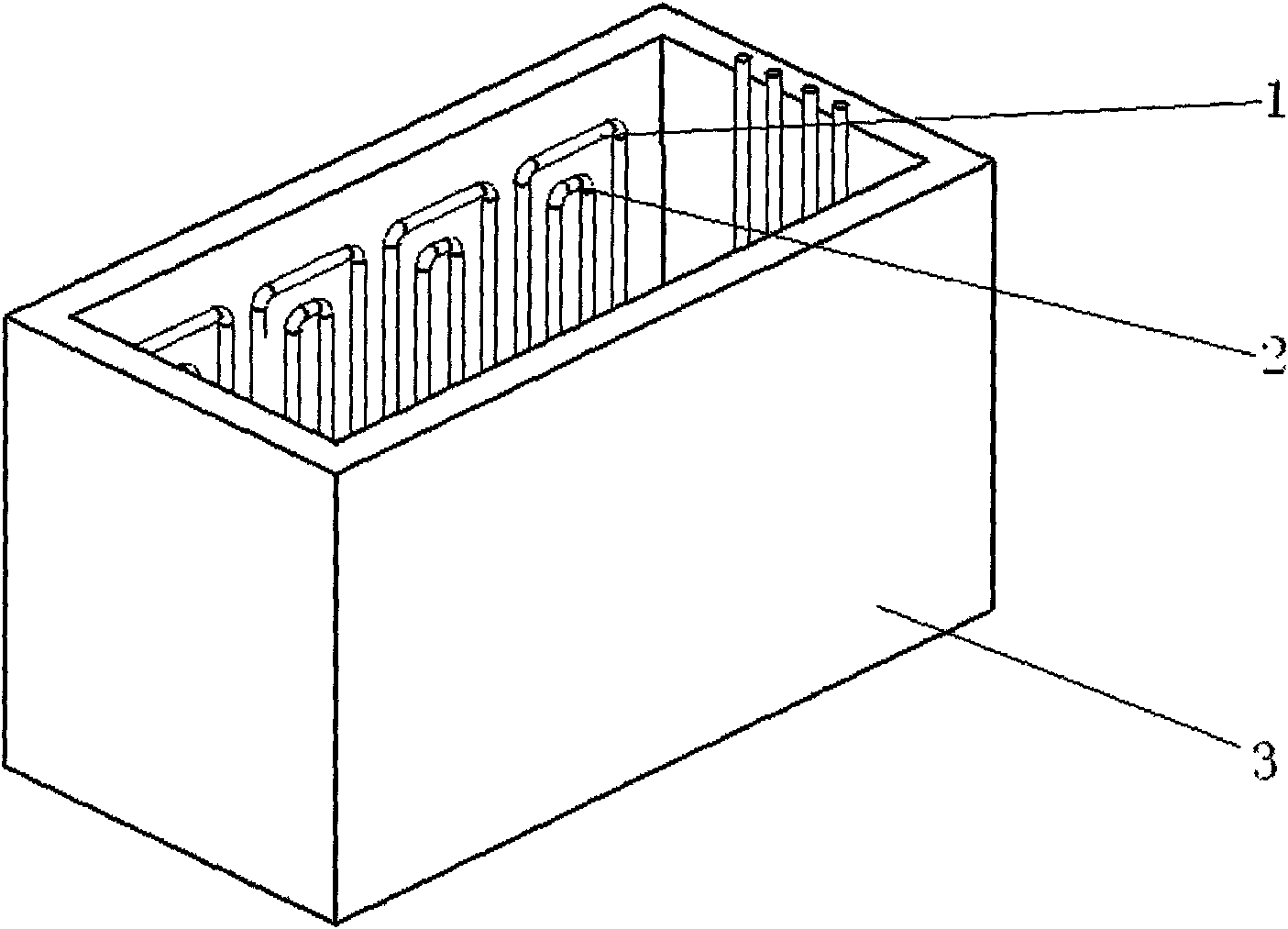

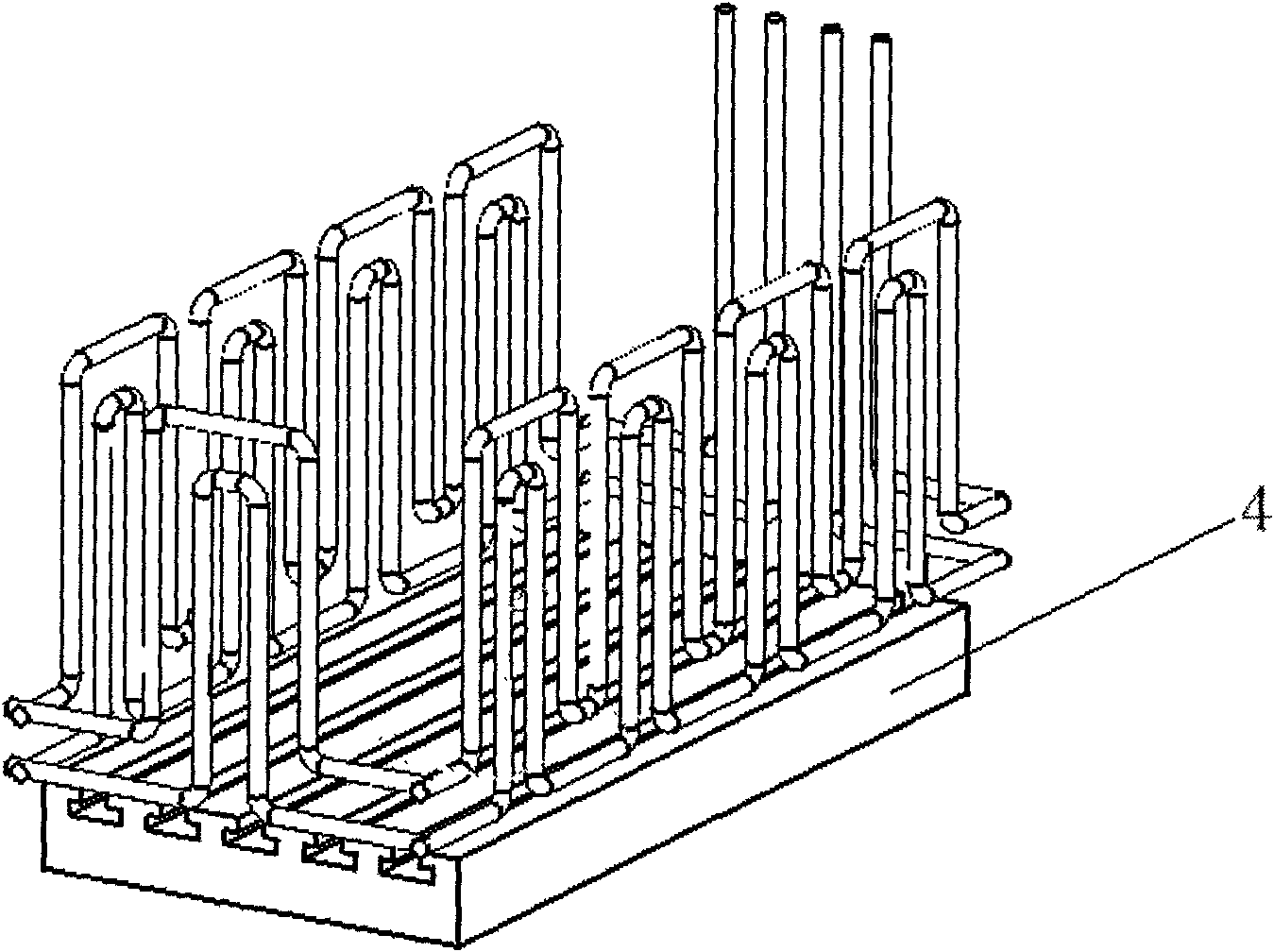

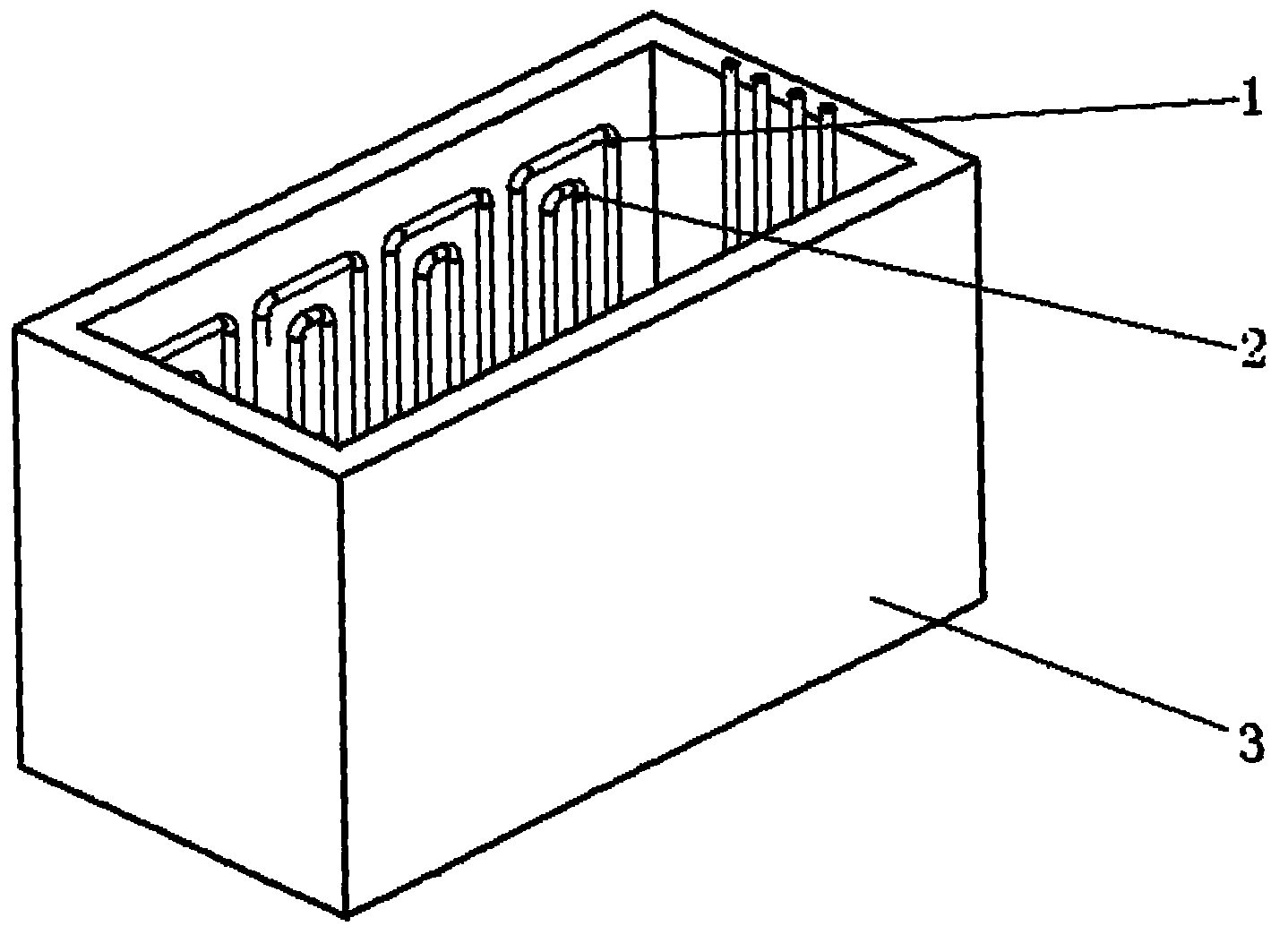

[0023] Such as figure 1 , figure 2 As shown, the present invention is provided on the bottom surface of the cooling tank 3 with a T-slot worktable 4 fixed with a positioning mechanism for irregular non-metallic workpieces to be processed, and the four inner sides of the cooling tank 3 are provided with a condenser tube 1 and heating The tube 2, the condenser tube 1 and the heating tube 2 are respectively connected with the refrigeration device and the heating device.

[0024] The working principle of the present invention is:

[0025] 1) Position the irregular non-metallic workpiece to be processed on the positioning mechanism, and then place the irregular non-metallic workpiece and the positioning mechanism together on the bottom surface of the cooling tank to fix; according to the characteristics of the irregular non-metallic workpiece to be processed, The six-point p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com