Heat treatment process of limited deep hardening of groove end of shifting fork and special device thereof

A technology of shifting fork groove and depth, applied in heat treatment equipment, heat treatment furnace, manufacturing tools, etc., can solve problems such as failure to meet process requirements, difficult to meet millimeter level requirements, and process difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

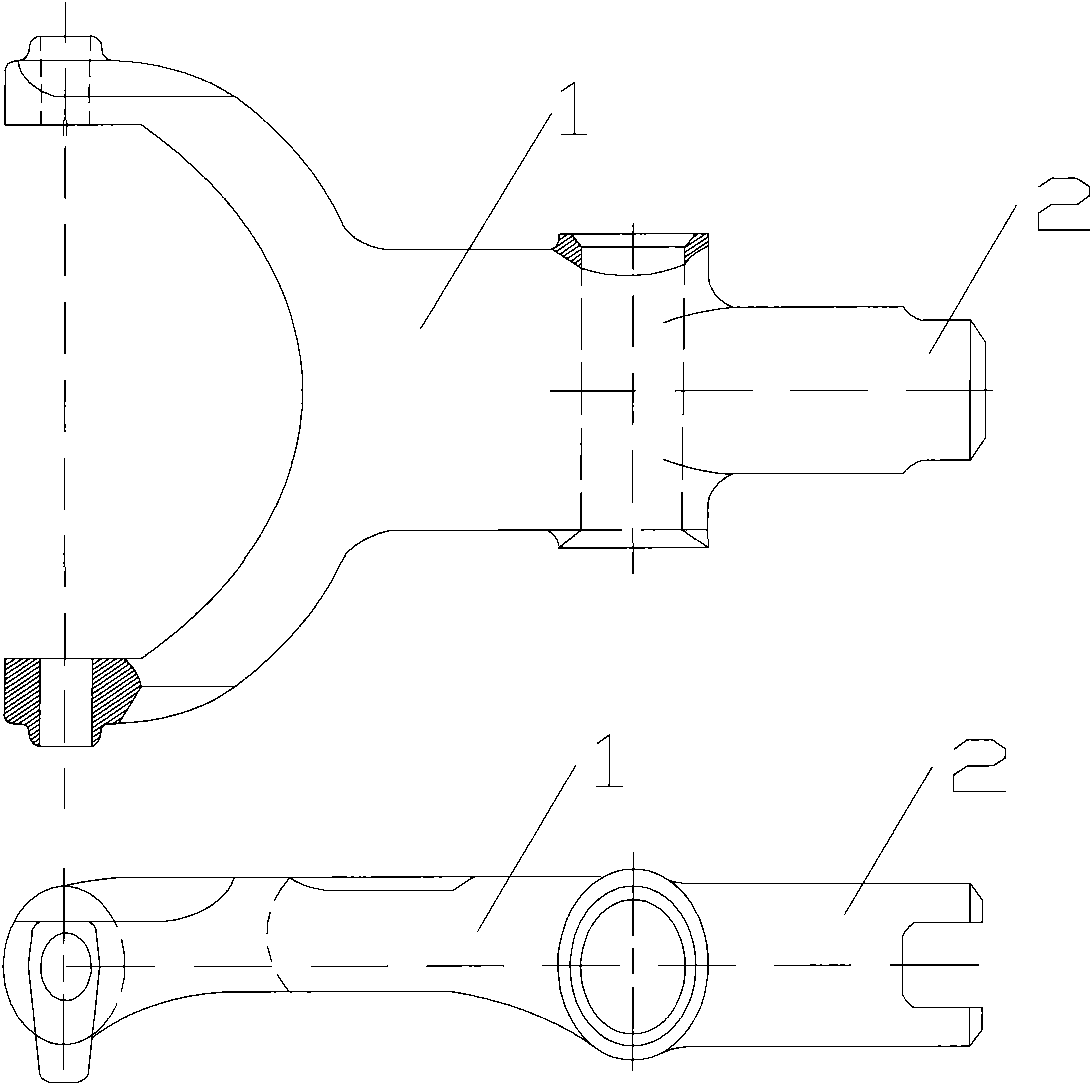

[0018] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

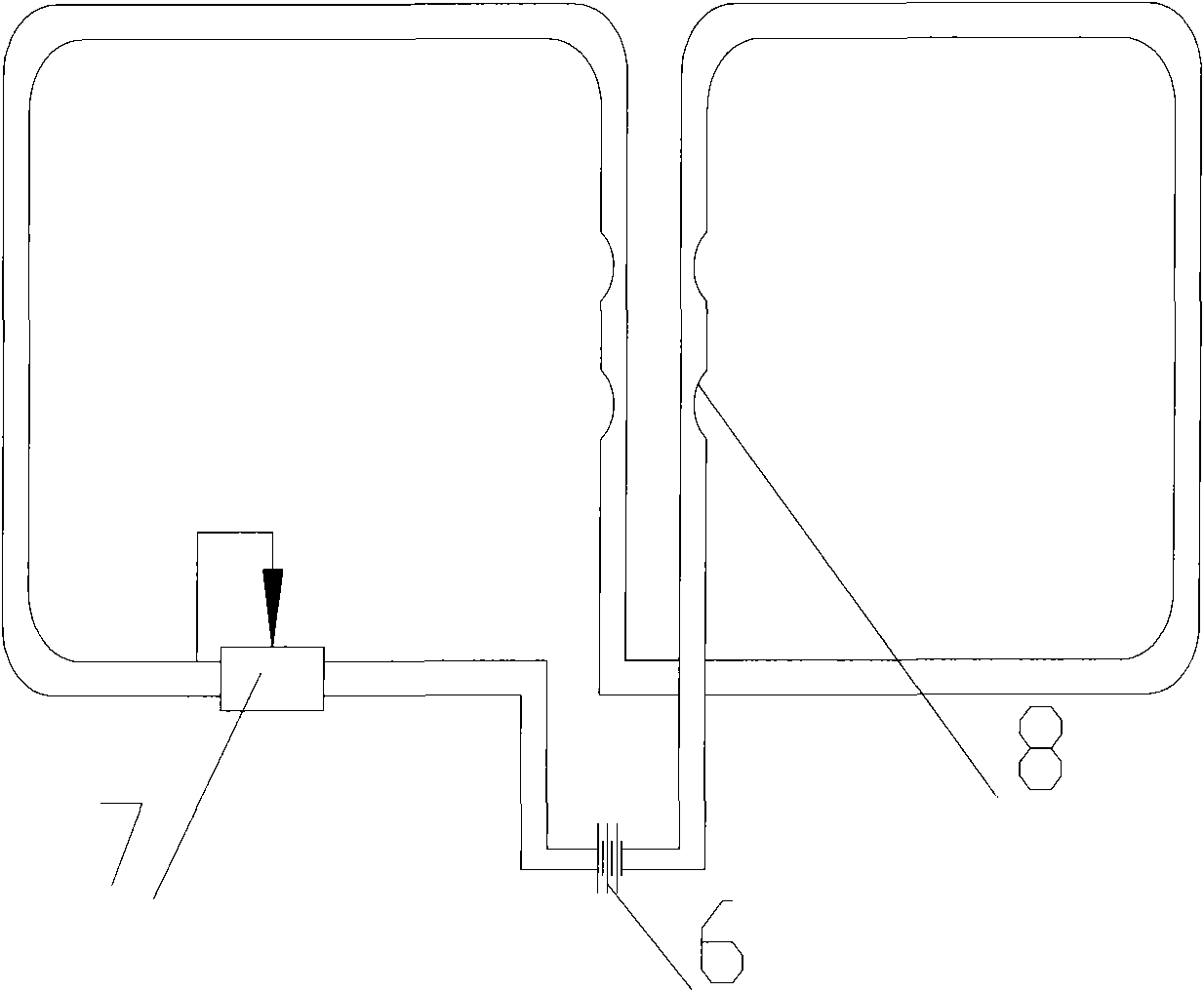

[0019] As shown in the accompanying drawings, the present invention is a heat treatment process for hardening the groove end of the shift fork with limited depth, which includes the following steps: (1) partially Carry out high-frequency induction quenching treatment; (2) Cooling the groove end by spraying cooling water through the jet pipe; (3) Partial tempering of the groove end.

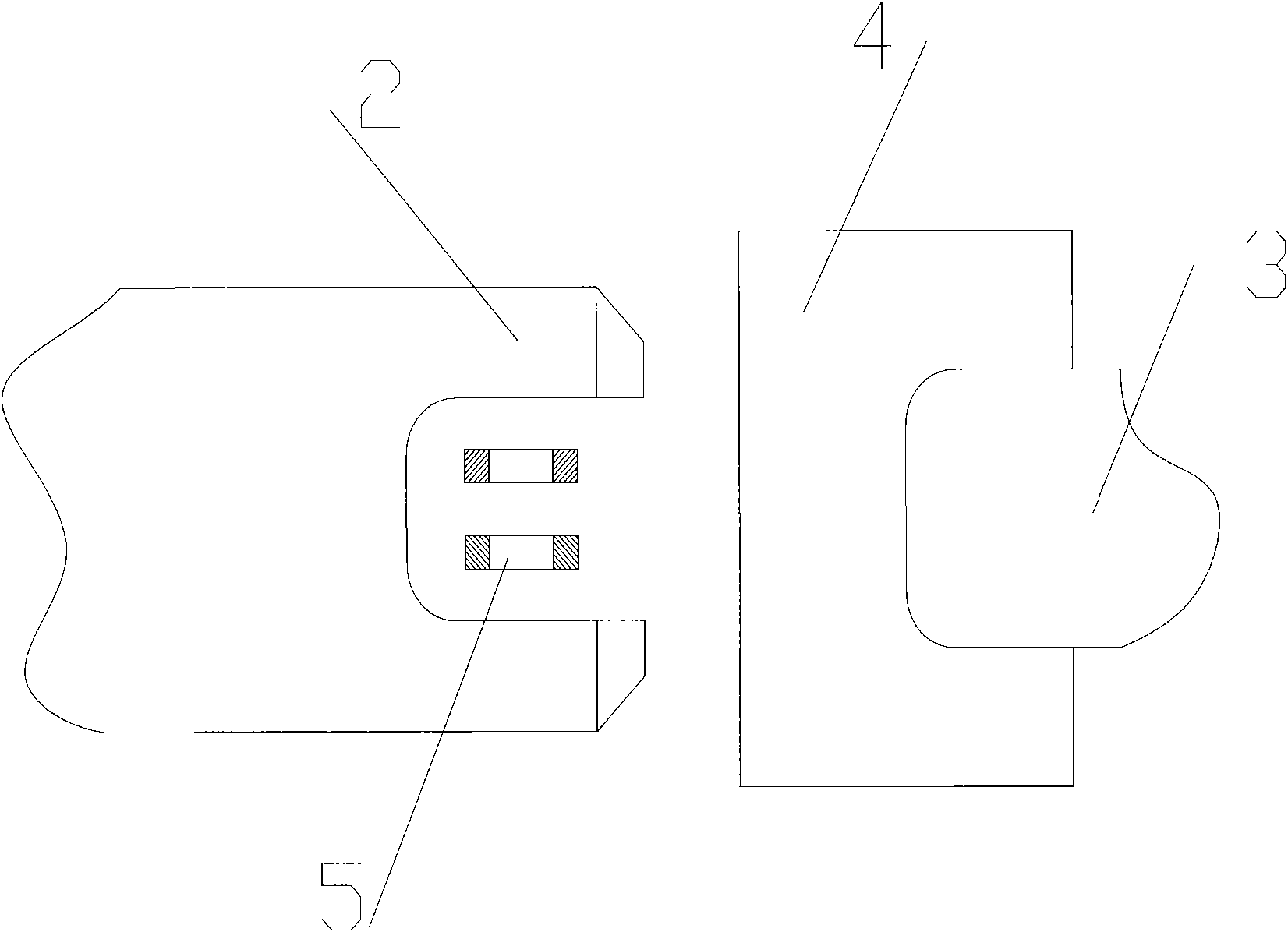

[0020] In order to avoid insufficient hardness at the front edge of the groove end, a magnetizer is added at the front of the groove end. The magnetizer is a silicon steel sheet to reduce the dissipation of the magnetic force lines and improve the induction efficiency.

[0021] The temperature of the cooling water used is 35°C±5°C, and the spray pipe adopts a flat spray pipe. At the same time, in order to avoid the possibility of high hardness outside the fork groove end, compressed ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com