Compression releasing engine braking method and device

An engine brake and release type technology, applied in engine control, engine components, machine/engine, etc., can solve the problems of increasing engine height and weight, inconvenient installation and debugging, poor reliability and durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

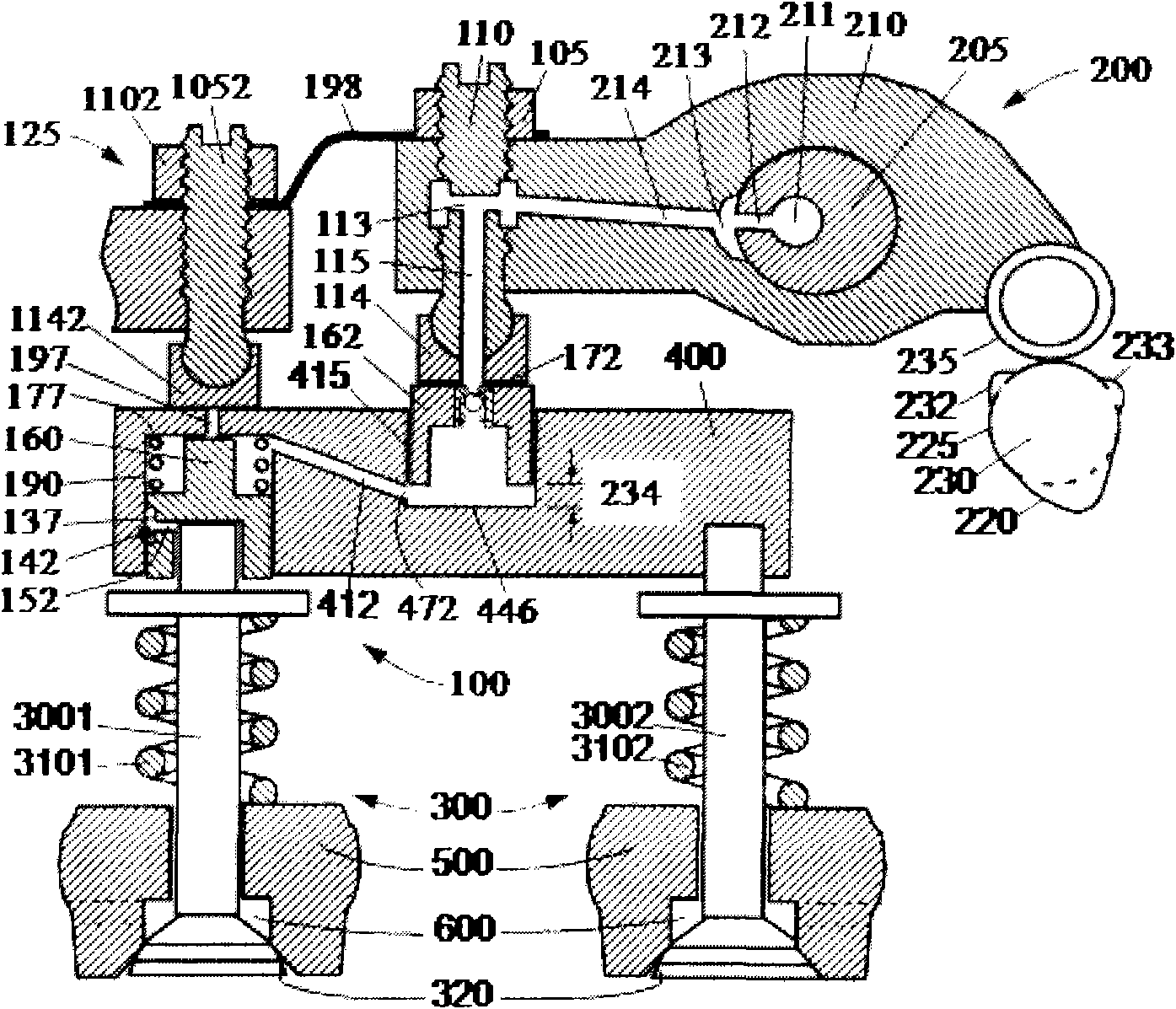

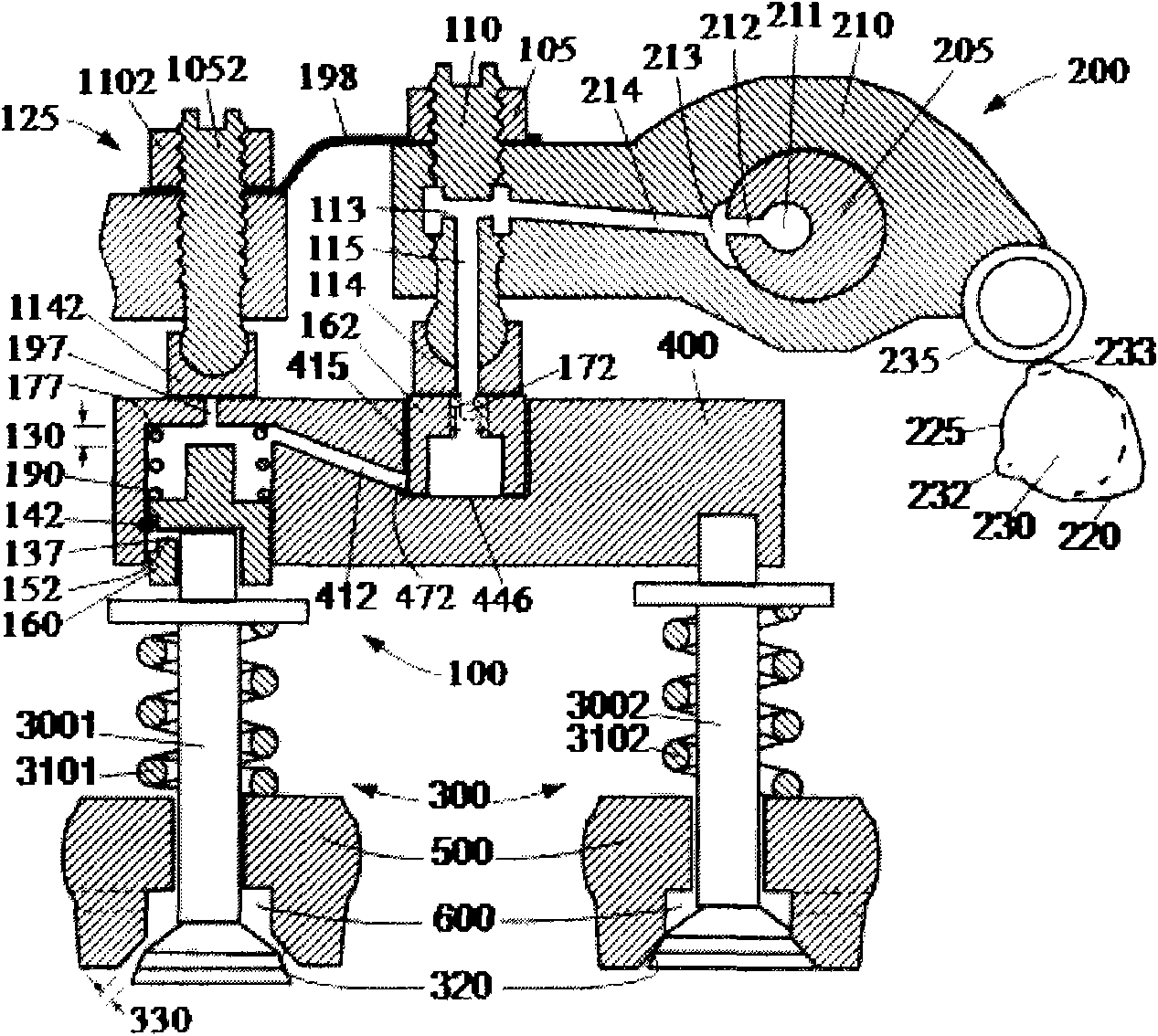

[0082] Such as figure 1 with figure 2 As shown, the cam 230 of the first embodiment of the compression release engine braking device of the present invention is respectively at the position of the inner base circle 225 and the position of the highest lift of the braking boss during braking. figure 1 with figure 2 It includes three main components: the exhaust valve actuator 200, the exhaust valve 300 (including the first exhaust valve 3001 and the second exhaust valve 3002) and the engine brake driving mechanism 100.

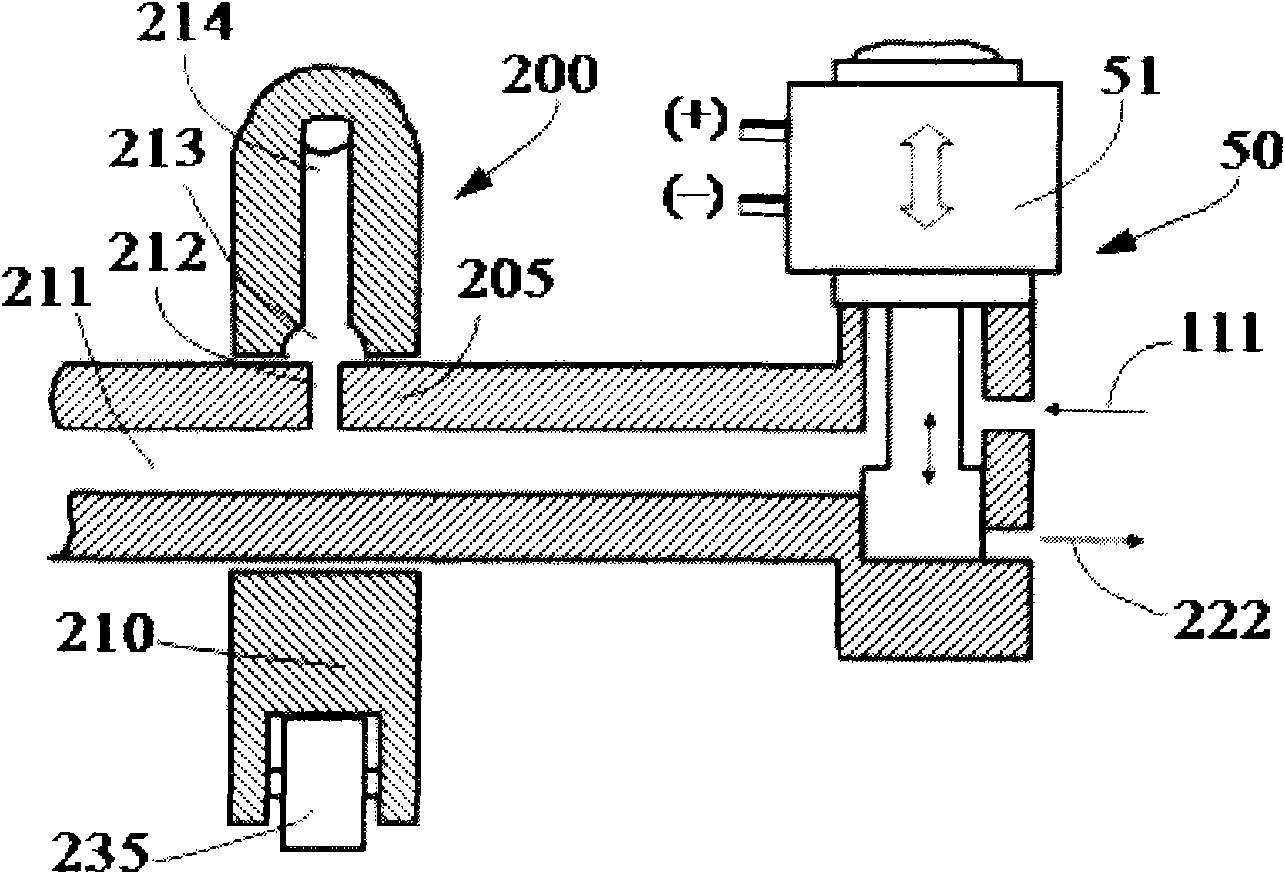

[0083] Exhaust valve actuator 200 includes cam 230 , cam follower 235 , rocker arm 210 and valve bridge 400 . Collectively, exhaust valve actuator 200 and exhaust valve 300 may be referred to as an exhaust valve drive train. Usually, one end of the rocker arm 210 (the side close to the valve bridge 400 or the side close to the cam 230 ) is provided with a valve clearance adjustment system. The valve gap adjusting system in this embodiment is composed of a ...

Embodiment 2

[0106] Such as Figure 9 with Figure 10 As shown, the second embodiment of the compression release engine braking device of the present invention has the cam in the position of the inner base circle during non-braking and braking. The difference between this embodiment and the first embodiment is that this embodiment uses a different brake bracket 125 . The brake bracket 125 located above the valve bridge 400 has two main functions: one is to support the valve bridge 400 during engine braking, prevent or limit the upward movement of the valve bridge 400, and close the oil discharge channel above the auxiliary piston hole 190 197, bear the braking load transmitted from the brake exhaust valve 3001; second, in each cycle of engine braking, when the top of the integrated exhaust boss 220 pushes the valve bridge down, the secondary piston hole is opened The oil unloading channel 197 above the 190 unloads the oil, and resets the valve lift curve of the brake exhaust valve 3001. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com