Magnet valve with a valve housing

A technology of solenoid valve and valve shell, applied in the field of solenoid valve, can solve problems such as high cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

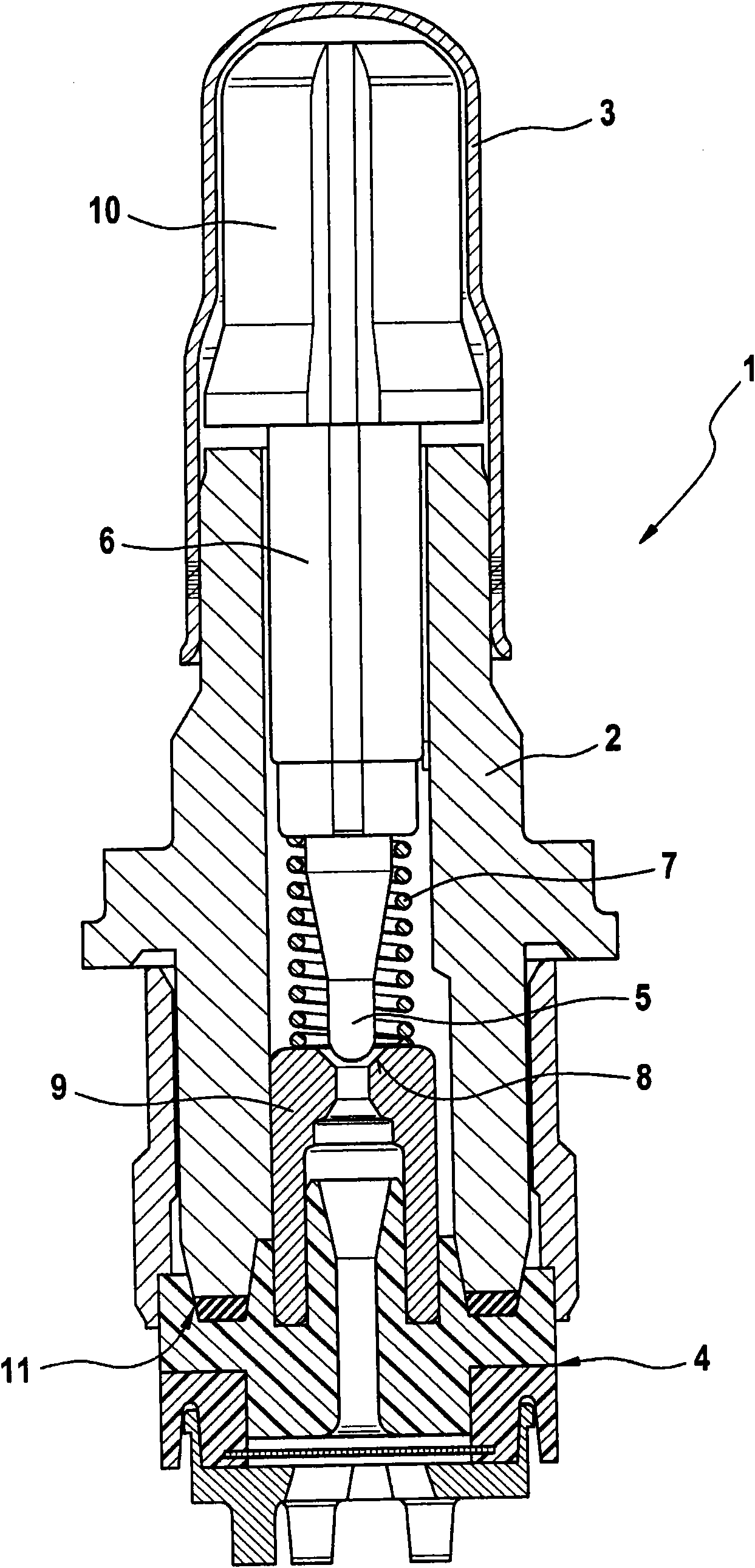

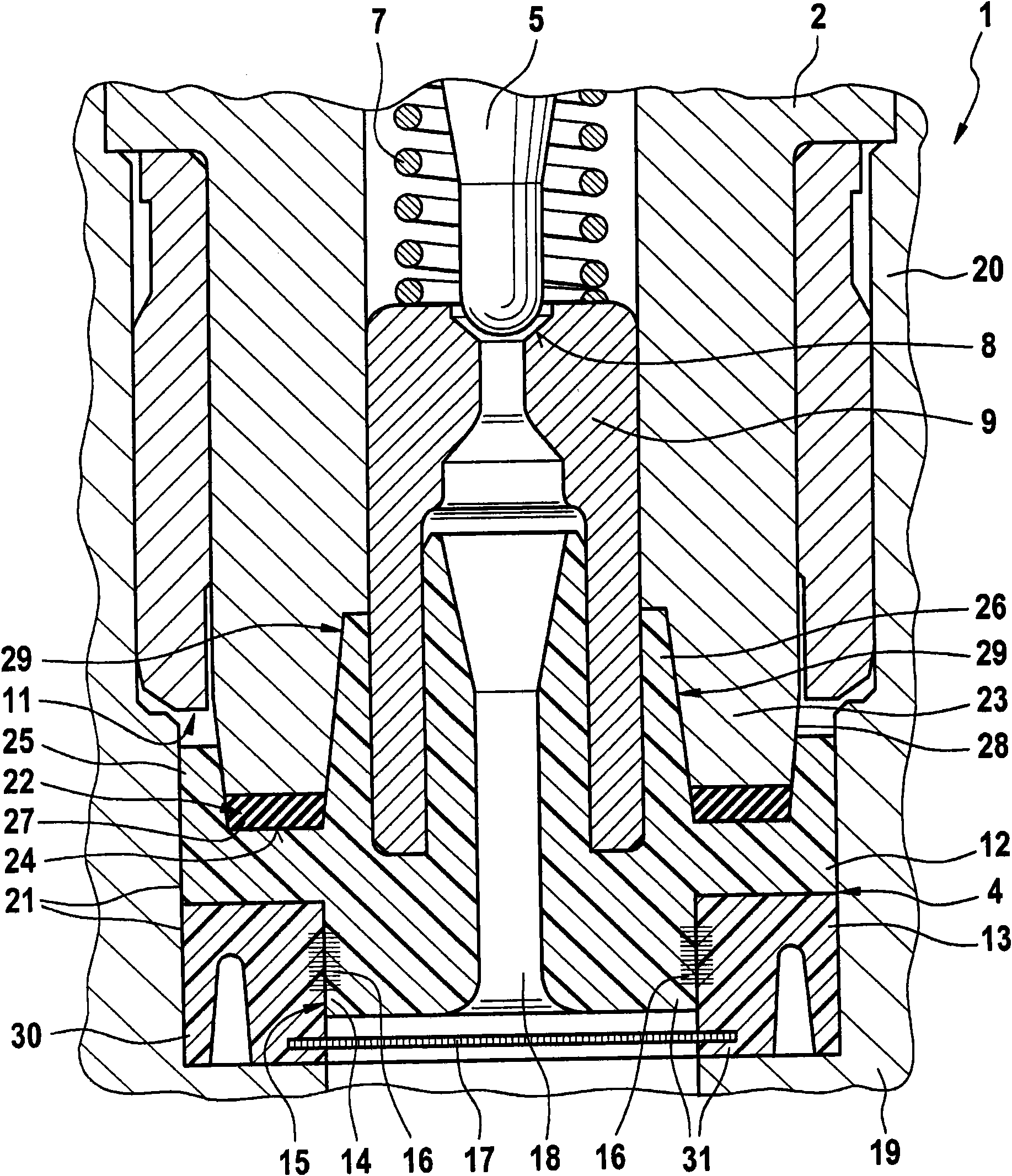

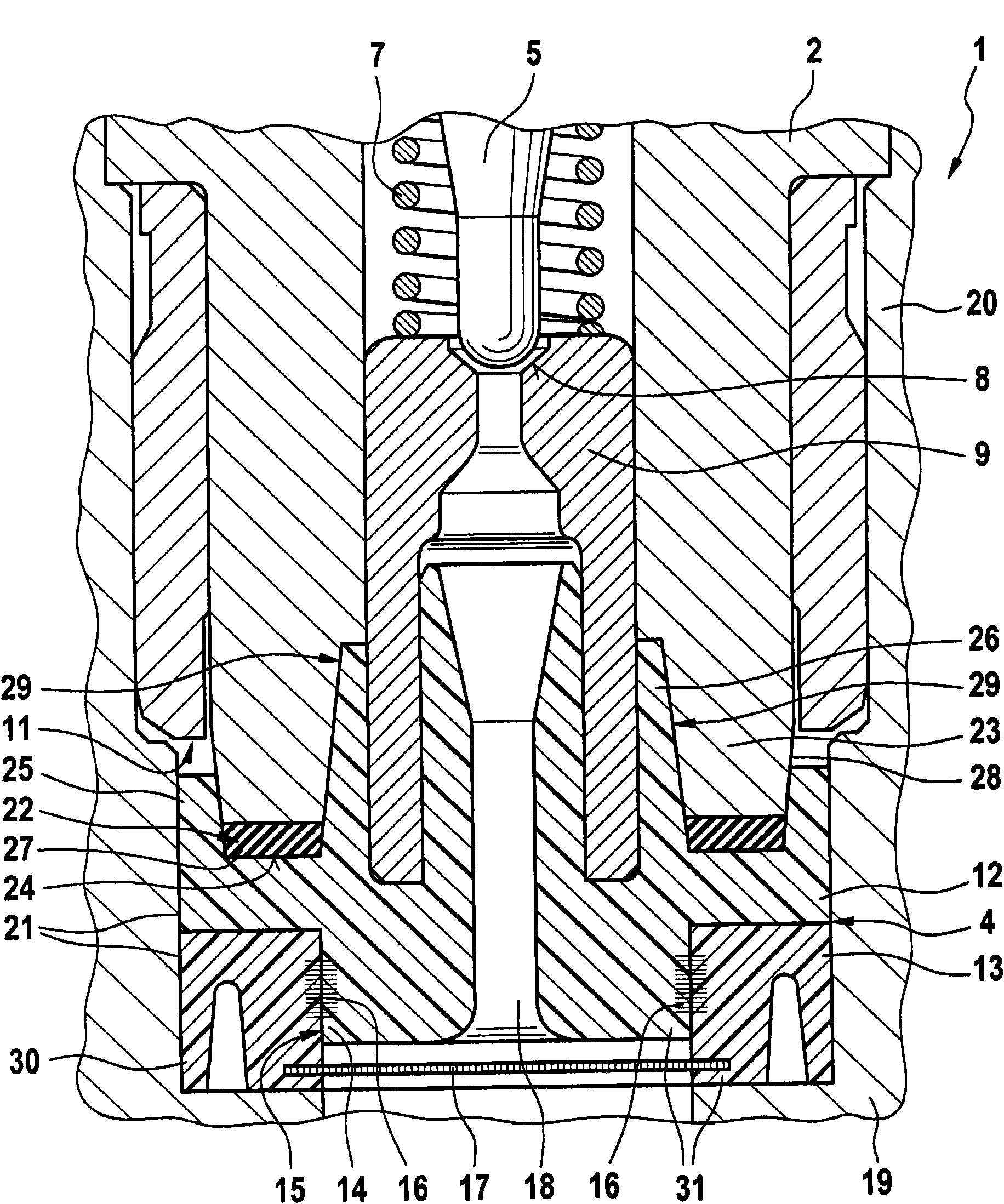

[0019] figure 1 A solenoid valve 1 with a valve housing 2 is shown, which is closed hermetically by a housing cap 3 on the upper side and a sealing body 4 on the lower side. The valve lifter 5 is longitudinally movably supported inside the valve housing 2. The valve lifter is in contact with the armature 6 axially in the direction of the housing cap 3 and the spiral pressure spring surrounding the valve lifter 5 7 works together, wherein the spiral compression spring 7 is supported on the armature 6 on one side, and on the other side is supported on the valve body 9 adjacent to the valve tappet 5 in the axial direction, the valve body There is a valve seat 8 for opening and closing by the valve tappet 5. The valve housing 2 is substantially configured as a hollow cylindrical shape for accommodating an armature 6, a valve tappet 5 connected to the armature, a valve body 9 connected to the valve tappet and having a valve seat 8 and a valve The position of the tappet 5 is opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com