U-shaped channel combined heat pipe receiver

A combined type and receiver technology, applied in the field of U-shaped channel combined heat pipe receiver, can solve the problems of unfavorable Stirling engine operation, increased gas flow resistance, and decreased heat transfer capacity, achieving good sealing and replacement Good thermal effect, enhanced stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described with reference to the accompanying drawings.

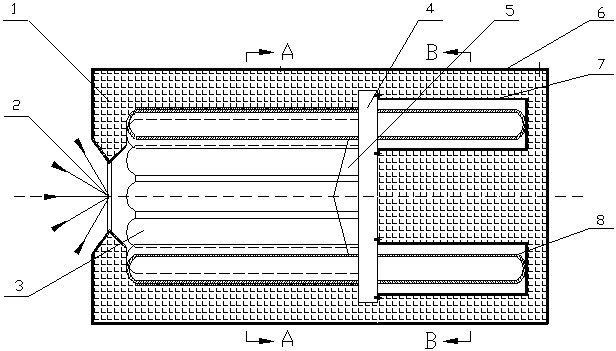

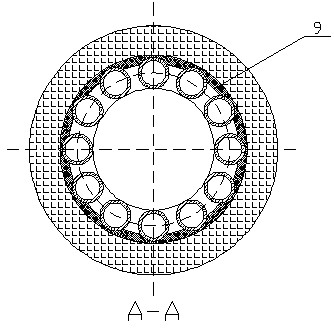

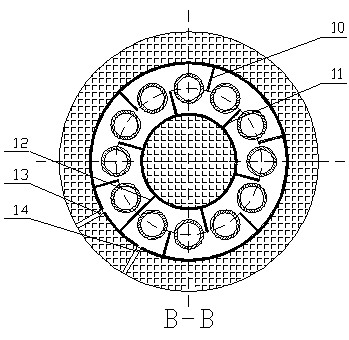

[0020] Such as figure 1 , figure 2 , image 3 As shown, the U-shaped channel combined solar heat pipe receiver includes a high-temperature-resistant insulation layer 1, a lighting hole 2, a heat-absorbing section of the heat pipe group 3, a partition plate 4, a diffuse reflection cone 5, an aluminum alloy shell 6, and an annular sleeve 7 , heat pipe group condensation section 8, annular radiation absorbing rib 9, outer wall semi-enclosed air flow baffle 10, inner wall semi-enclosed air flow baffle 11, fully enclosed air flow baffle 12, gas inlet 13 and gas outlet 14; heat pipe group suction The heat section 3 and the condensation section 8 of the heat pipe group pass through the dividing plate, and are evenly arranged in a ring in the center. The annular radiation absorbing rib 9 is in contact with the heat absorbing section 3 of the heat pipe group. The reflective cone 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com