Base broth powder and method for producing same

A basic, broth technology, used in food preparation, egg preservation by freezing/cooling, food science, etc., can solve the problems of heavy, perishable, difficult to provide taste, etc., and achieve the effect of ensuring storability and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

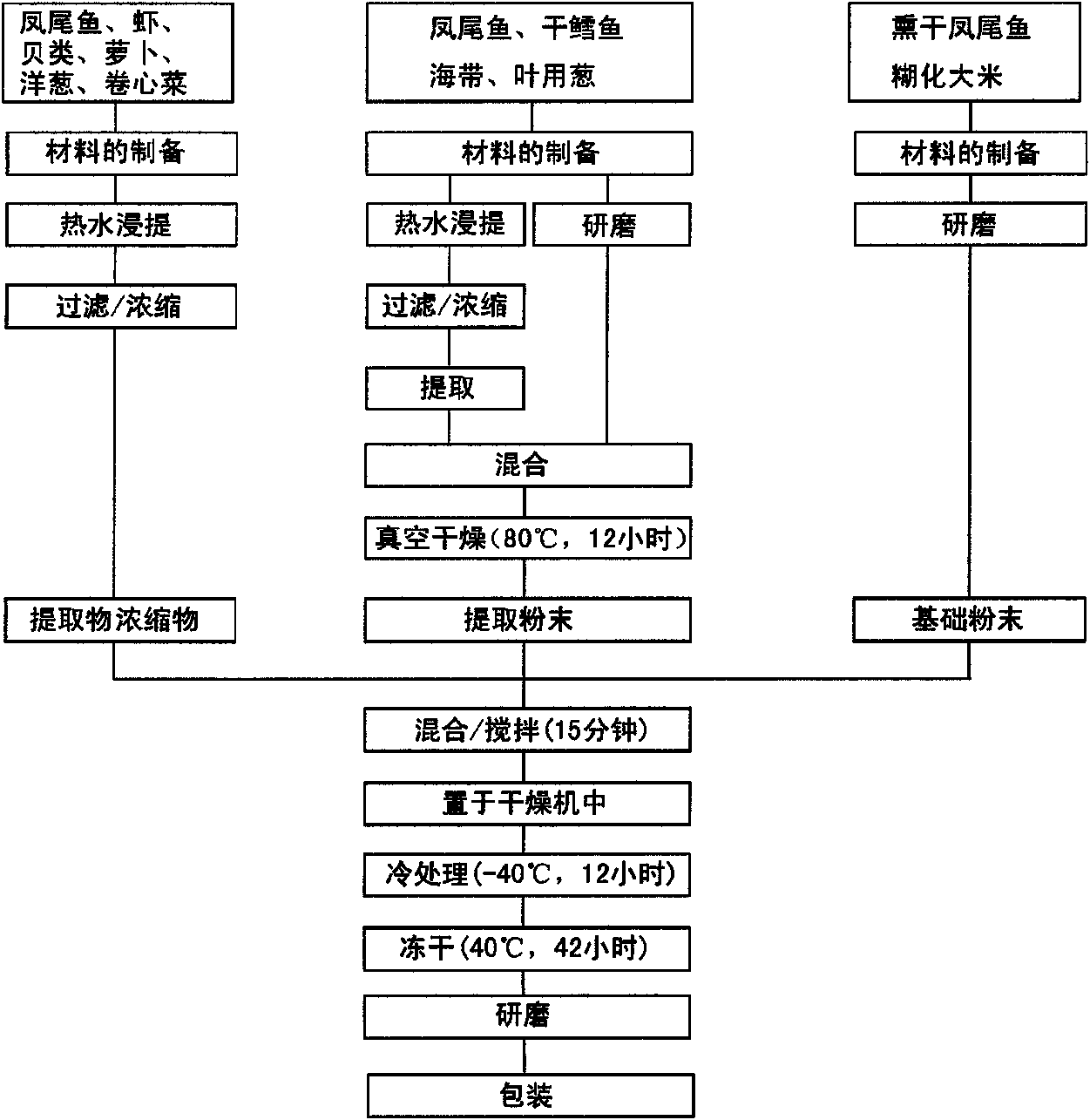

[0028] Embodiment 1: the preparation of base broth powder material

[0029] Anchovy, dried cod, shrimp, shellfish, radish, onion, and cabbage were prepared and extracted through hot water, respectively, and the obtained extracts were concentrated by vacuum filtration to make extract concentrates each having a Brix of 55-65.

[0030] Then, prepare the kelp, anchovies, dried cod and green onions and soak them in hot water. The obtained extracts were concentrated by filtration under reduced pressure to prepare extract concentrates each having a Brix content of 10-30. Meanwhile, grind kelp, anchovies, dried cod and leaf shallots into powder. The extract concentrate and powder were mixed, and the mixture was dried in vacuum at 80° C. for 12 hours and pulverized into powder, thereby obtaining an extract powder.

[0031] Next, the anchovies were prepared to be smoked and dried, and 90% of the anchovies were passed through a 25-mesh sieve to provide a powder, and the rice flour was ...

Embodiment 2

[0032] Embodiment 2: the preparation of basic bouillon powder

[0033]The extract concentrate, extract powder and base powder prepared in Example 1 were mixed in a mixer for 15 minutes at the content ratios shown in Table 1 below. The obtained mixture was placed in a desiccator and frozen in a -40°C freezer for 12 hours. The mixture was dried under reduced pressure at 40° C. for 42 hours, and pulverized to obtain a base broth powder.

[0034]

[0035] The composition of the material of the base bouillon powder of embodiment 2

[0036]

[0037] The components in Table 1 can be represented by the component composition ratios of the following raw materials.

[0038]

[0039]

[0040]

[0041] 10 g of base bouillon powder prepared as described above was added to 1 L of water and boiled. After simmering for 5 minutes, a base broth is obtained.

Embodiment 3 and 4

[0042] Examples 3 and 4: Preparation of base bouillon powder

[0043] The base bouillon powder was prepared in the same manner as in Example 2, except that seafood, cooking vegetables and rice noodles were mixed in the mixing ratios listed in Table 2 and Table 3 below.

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com