Method for curing salted eggs

A technology of salted eggs and pickling liquid, which is applied in the field of food processing, can solve the problems of salty egg whites and other problems, and achieve the effect of golden egg, saving consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

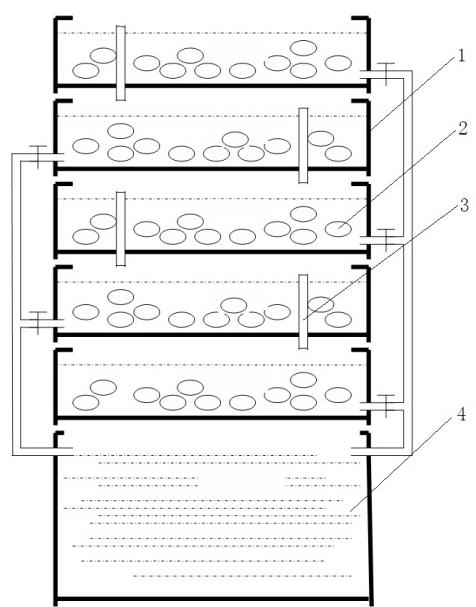

Image

Examples

Embodiment 1

[0050] Raw materials of fresh poultry eggs: select fresh poultry eggs, sort, grade, wash, and dry for later use;

[0051]The first pickling: prepare a 25% concentration of pickling solution, put the graded and washed fresh eggs into the pickling box (tank), make the fresh eggs completely submerged in the pickling solution, and marinate for 15 days. Drain the first pickling liquid into the pickling liquid recovery tank, and recycle the pickling liquid for reuse; inject the second pickling liquid into the pickling box: prepare a 15% concentration of pickling liquid, so that the fresh eggs are completely submerged In the pickling liquid, marinate for 10 days. Drain the second pickling liquid into the pickling liquid recovery pool for recycling and reuse of the pickling liquid; inject three pickling liquids into the pickling box: prepare a 5% concentration of pickling liquid to make fresh eggs completely Immerse in the pickling liquid and marinate for 5 days; discharge the third ...

Embodiment 2

[0053] Raw materials of fresh poultry eggs: select fresh poultry eggs, sort, grade, wash, and dry for later use;

[0054] The first pickling: prepare a 25% concentration of pickling solution, put the graded and washed fresh eggs into the pickling box (tank), so that the fresh eggs are completely submerged in the pickling solution, and marinate for 20 days. Discharge the first pickling liquid into the pickling liquid recovery pool for recycling and reuse of the pickling liquid; inject the second pickling liquid into the pickling box: prepare a 15% concentration of pickling liquid to fully submerge the fresh eggs In the pickling liquid, marinate for 5 days. Discharge the second pickling liquid into the pickling liquid recovery pool for recycling and reuse of the pickling liquid; Inject three pickling liquids into the pickling box: prepare a 5% concentration of pickling liquid to make all fresh eggs Immerse in the pickling liquid and marinate for 5 days; discharge the third pick...

Embodiment 3

[0056] Raw materials of fresh poultry eggs: select fresh poultry eggs, sort, grade, wash, and dry for later use;

[0057] The first pickling: prepare a 25% concentration of pickling solution, put the graded and washed fresh eggs into the pickling box (tank), make the fresh eggs completely submerged in the pickling solution, and marinate for 25 days. Drain the first pickling liquid into the pickling liquid recovery tank, and recycle the pickling liquid for reuse; Inject pure water pickling liquid into the pickling box: prepare pure water, make the fresh eggs fully submerged in the liquid, immerse 5 days; discharge the effluent, drain the pure water pickling solution into the pickling solution recovery pool, and recycle the pickling solution for reuse; take out the pickled fresh eggs, vacuum pack and autoclave after cleaning, and pack the finished product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com